Soybean meal adhesive for blockboards, and preparation method thereof

A technology for blockboard and adhesive, applied in the field of boards, can solve the problems of limited industrial application of wood-based panels, such as durability, free formaldehyde release, poor water-resistant bonding performance, etc. performance, the effect of improving the initial viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

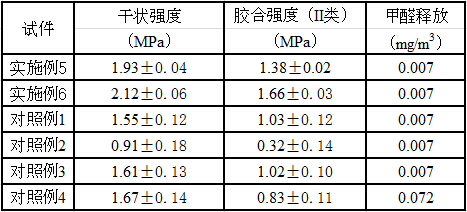

Examples

Embodiment 1

[0029] A soybean meal adhesive for blockboard, comprising the following components: 22g soybean meal powder, 86g distilled water, 2g trypsin, 1g composite viscosity modifier, 2g branched polymer crosslinking agent, 0.04g calcium phosphate;

[0030] The preparation method of described branched polymer crosslinking agent comprises the steps:

[0031] S1. After reacting phthalic acid, maleic anhydride, and diethylenetriamine at 150°C, cool down and dilute to obtain a hyperbranched amino polymer;

[0032] S2. After mixing epichlorohydrin, solvent, and the hyperbranched amino polymer at 60°C for reaction, adjust the pH to 8 to obtain the branched polymer crosslinking agent;

[0033] The composite viscosity regulator includes polyvinyl alcohol, sodium carboxymethylcellulose, and bentonite at a mass ratio of 1:1:5.

Embodiment 2

[0035] A soybean meal adhesive for blockboards, comprising the following components: 26g of soybean meal powder with a protein content of 43%-45% and a particle size of 160 meshes, 86g of distilled water with a pH of 7.3-7.5, 3g of trypsin, and 2g of compound viscosity Regulator, 3g branched polymer crosslinking agent, 0.08g calcium phosphate;

[0036] The preparation method of described branched polymer crosslinking agent comprises the steps:

[0037] S1. After reacting 0.9mol phthalic acid, 0.1mol maleic anhydride, and 1.4mol diethylenetriamine at 150°C for 3 hours, cool down and dilute with water to obtain a hyperbranched amino polymer, add water to dilute to a hyperbranched amino polymer The mass fraction of is 25%;

[0038] S2. Mix 25g of epichlorohydrin, 50g of water, and 50g of the hyperbranched amino polymer with a mass fraction of 25% and react at 60°C, then adjust the pH to 8 to obtain the branched polymer crosslinking agent.

[0039] The composite viscosity regula...

Embodiment 3

[0041] A soybean meal adhesive for blockboard, comprising the following components: 25g protein content is 43%-45%, particle size is 160 mesh soybean meal powder, 86g pH is 7.3-7.5 distilled water, 2.5g trypsin, 1.5g Compound viscosity modifier, 2.5g branched polymer crosslinking agent, 0.06g calcium phosphate;

[0042] The preparation method of described branched polymer crosslinking agent comprises the steps:

[0043] S1. After reacting 1.8mol phthalic acid, 0.2mol maleic anhydride, and 2.8mol diethylenetriamine at 150°C for 3 hours, cool down and dilute with water to obtain a hyperbranched amino polymer, add water to dilute to a hyperbranched amino polymer The mass fraction of is 30%;

[0044] S2. Mix 50g of epichlorohydrin, 100g of water, and 100g of the hyperbranched amino polymer with a mass fraction of 25% and react at 60°C, then adjust the pH to 8 to obtain the branched polymer crosslinking agent.

[0045] The composite viscosity regulator includes polyvinyl alcohol,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bonding strength | aaaaa | aaaaa |

| Dry strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com