Aqueous macromolecule-isocyanic ester stalk artificial board and preparation thereof

A water-based polymer and isocyanate technology, which is applied in the field of wood science and engineering, can solve the problems of loose blanks and slabs, poor slab pre-pressing performance, and high production costs, and achieve low manufacturing costs, good pre-pressing performance, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

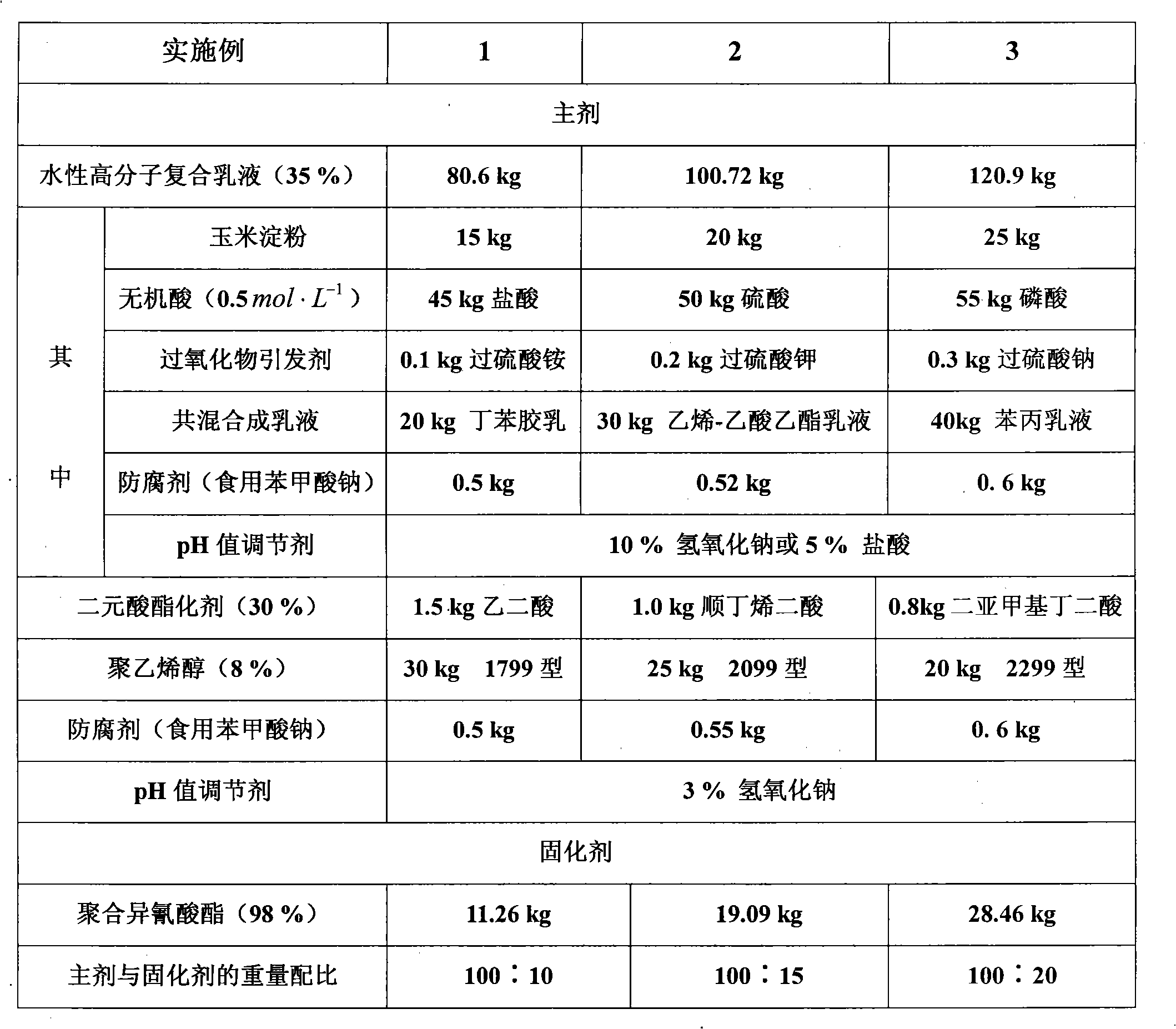

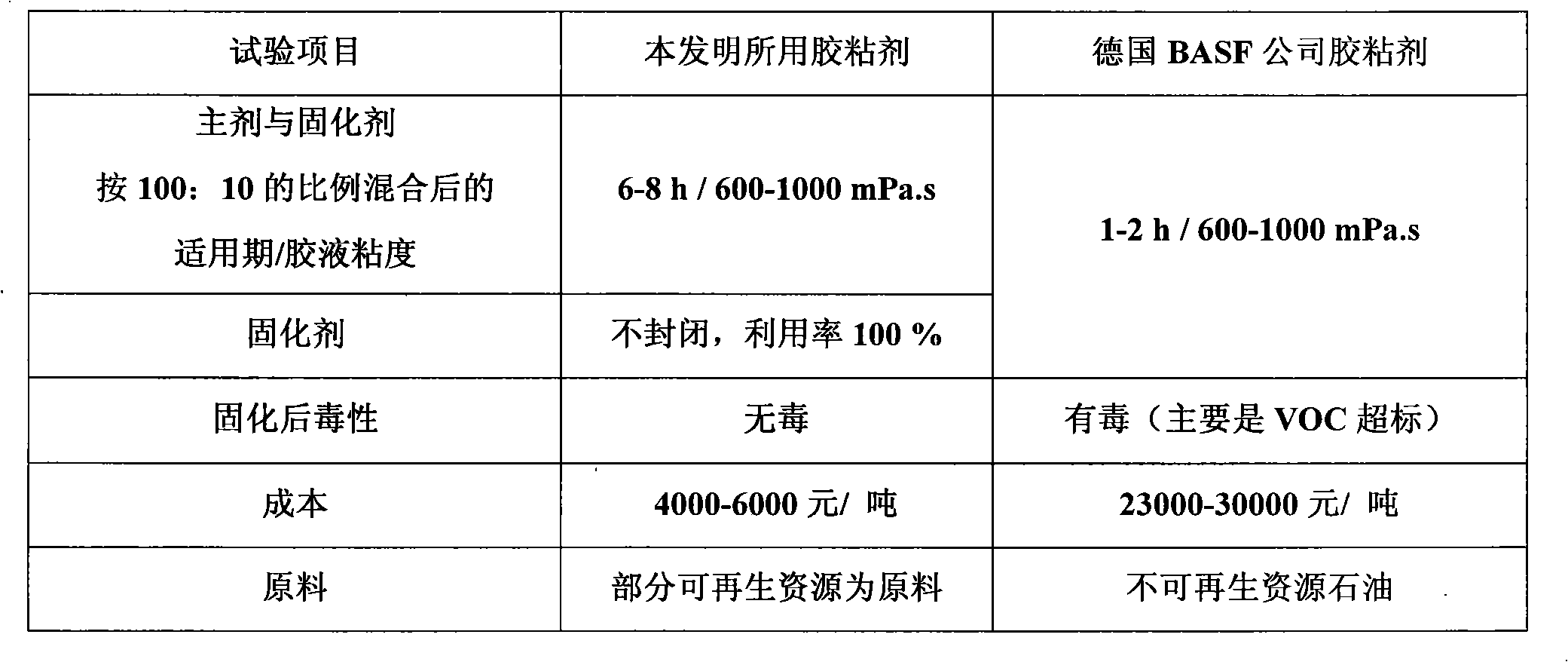

[0041] Example 1-3: Preparation of Water-based Polymer-isocyanate Adhesive for Water-Based Polymer-Isocyanate Straw Wood-based Panels of the Present Invention

[0042] The weight ratio of the raw materials used in each embodiment is shown in Table 1.

[0043] Table 1

[0044]

[0045]Its preparation method: (taking embodiment 1 as example, other embodiments are except raw material consumption difference, and preparation method is substantially identical with embodiment 1)

[0046] (1) Add 45kg of hydrochloric acid solution with a concentration of 0.5mol / L into the reactor with agitator and condenser, slowly add 15kg of cornstarch in the hydrochloric acid solution, stir vigorously to prepare cornstarch milk with a concentration of 35%, and heat up Keep warm at 55°C, add 0.1kg of ammonium persulfate to cornstarch milk, stir evenly, acidolysis and oxidation at 55°C, and pre-initiate for 30 minutes at the same time, adjust the pH value to 7 with 10% sodium hydroxide to obtain ...

Embodiment 4-6

[0049] Embodiment 4-6: Preparation of the water-based polymer-isocyanate straw-based panel of the present invention

[0050] The weight ratio of the raw materials used in each embodiment is shown in Table 2, and the water-based polymer-isocyanate glue is obtained from Example 1.

[0051] Table 2

[0052] Example

4

5

6

Raw material of straw

Rice straw with a moisture content of 8%

108.7kg

Wheat straw with a moisture content of 6%

106.4kg

Corn stover with 10% moisture content

111.2kg

Equivalent to dry straw

100kg

100kg

100kg

Water-based polymer-isocyanate glue

main ingredient

10kg

12kg

14.4kg

Water-based polymer-isocyanate glue

Hardener

1.0kg

1.2kg

1.44kg

Sizing method

Main agent mixing glue, curing agent spray glue

After the main agent and curing agent are mixed, the glue is mixed

Main agent mixing glue, cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com