Apparatus and process for treating breeding wastewater in pig farm and producing algal powder by utilizing microalgae

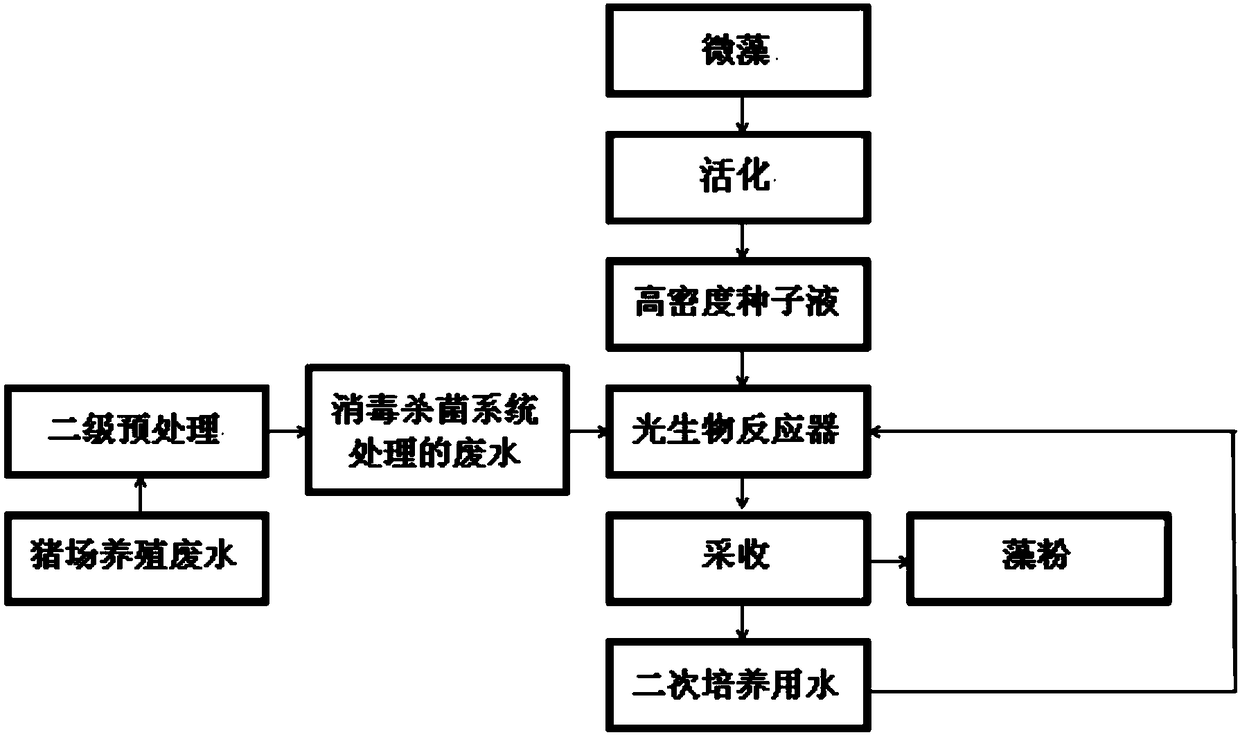

A technology for aquaculture wastewater and microalgae, applied in biological treatment devices, enzymology/microbiology devices, methods based on microorganisms, etc., can solve problems such as unstable biogas combustion, increased environmental pressure, and non-recyclable bacteria slime, etc., to achieve The effects of sustainable development and utilization, elimination or reduction of emissions, and short process cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

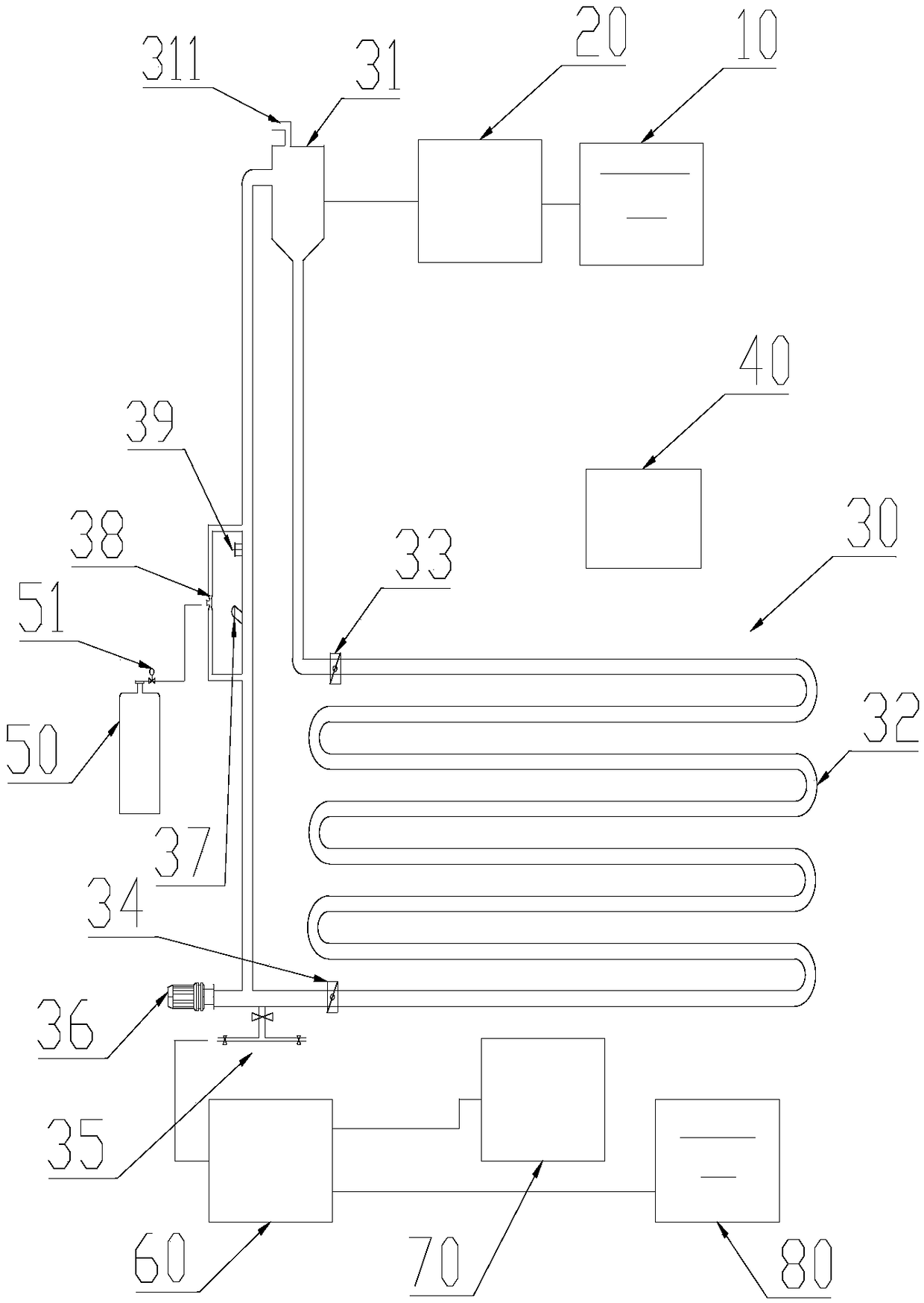

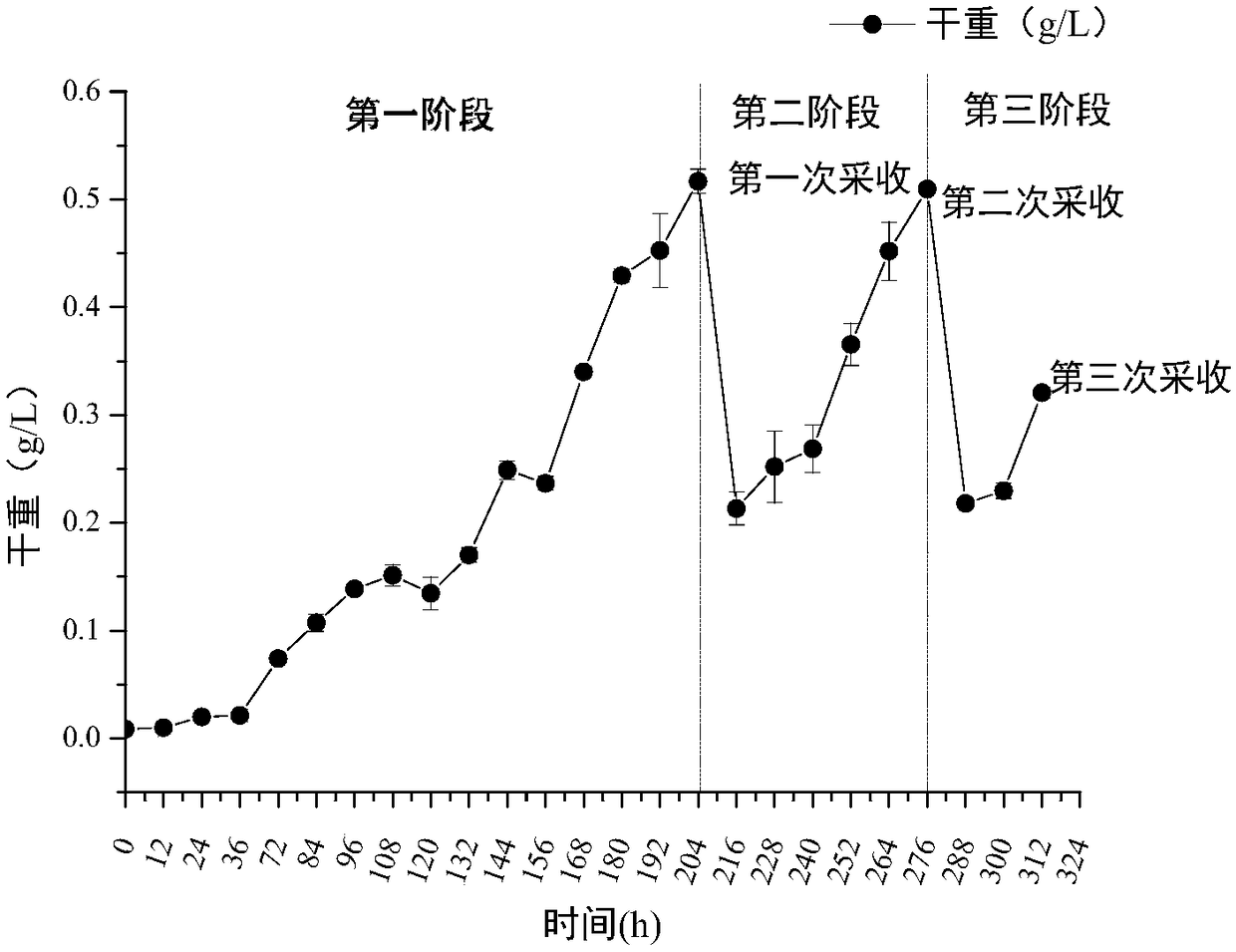

[0067] Example 1 Cultivation using pig farm wastewater in a 600L PVC pipe reactor

[0068] 1.1 Activation of algal species and preparation of seed solution

[0069] Pick a single algae colony from the activated Basal medium solid plate, and inoculate it into a 250mL Erlenmeyer flask filled with Basal medium (containing 10g / L glucose), and the filling volume is 100mL. Place them in a constant temperature shaker with a temperature of 28°C, 4000 lux, and 150 r / min and cultivate them for 6 days.

[0070] Using the improved Basal medium, in the ultra-clean workbench, the pre-cultivated first-grade Chlorella seed solution was inserted into a 2L large triangular flask according to the inoculum size 10% (v / v), and the liquid volume was 900mL. Cultivated under natural conditions in a large outdoor shaker.

[0071] 1.2 Pretreatment and inoculation of wastewater

[0072] The fermented biogas slurry of pig farming wastewater is passed through sand filtration and activated carbon filt...

Embodiment 2

[0090] Example 2 Cultivation of Chlorella using swine farm wastewater in a 1500L PVC pipe-type photobioreactor

[0091] 2.1 Activation of algae species and preparation of seed solution: the method is the same as 1.1

[0092] 2.2 Pretreatment and inoculation of wastewater

[0093] The fermented biogas slurry of pig farming wastewater is passed through sand filtration and activated carbon filtration for secondary treatment, and then passed into a 1500L photobioreactor. After 30 minutes of ozone disinfection, the gas is diffused for 2 hours. The seed solution of Chlorella pyrenoidosa was inoculated into the photobioreactor.

[0094] 2.3 Test method: the method is the same as 1.3

[0095] 2.4 Result analysis

[0096] Table 3 Pig farm wastewater and water quality parameters after pretreatment

[0097]

[0098]

[0099] Table 4 COD, TN, TP, NH 3 -N, PO 4 3- , chroma removal rate (%) statistics

[0100] parameter

COD

NH 3 -N

PO 4 3-

TN

...

Embodiment 3

[0104] Example 3 Cultivation of Chlorella using swine factory wastewater in a 1000L flat-lay film pipe reactor

[0105] 3.1 Activation of algae species and preparation of seed solution: the method is the same as 1.1

[0106] 3.2 Pretreatment and inoculation of wastewater

[0107] The fermented biogas slurry of pig farming wastewater is passed through sand filtration and activated carbon filtration for secondary treatment, and then passed into a 1000L flat film pipeline reactor. After 30 minutes of ozone disinfection, the gas is diffused for 2 hours. The seed solution of Chlorella pyrenoidosa was inoculated into the photobioreactor.

[0108] 3.3 Test method: the method is the same as 1.3

[0109] 3.4 Result analysis

[0110] Table 5 Pig farm wastewater and water quality parameters after pretreatment

[0111]

[0112] Table 6 COD, TN, TP, NH 3 -N, PO 4 3- , chroma removal rate (%) statistics

[0113] parameter

COD

NH 3 -N

PO 4 3-

TN

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com