E0-grade melamine modified urea-formaldehyde resin adhesive, and preparation method and application thereof

A technology of urea-formaldehyde resin glue and melamine, which is applied in adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve the problem of unstable formaldehyde emission, insufficient melamine reaction, and poor slab pre-compression in plywood and other problems, to achieve the effect of easy implementation, low price and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

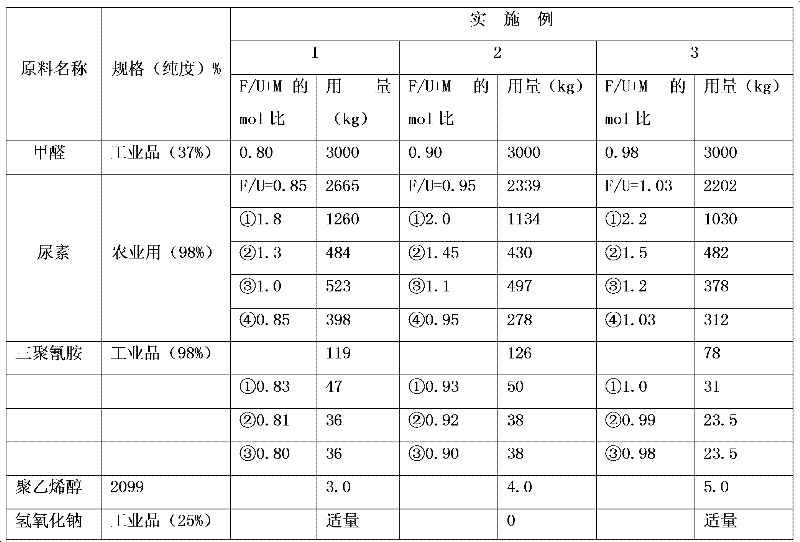

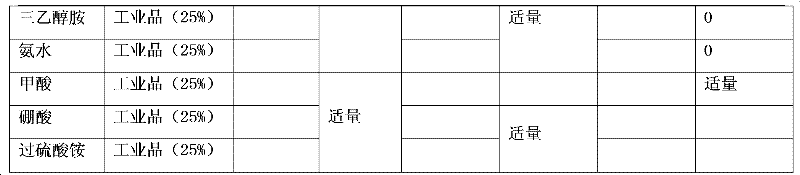

Examples

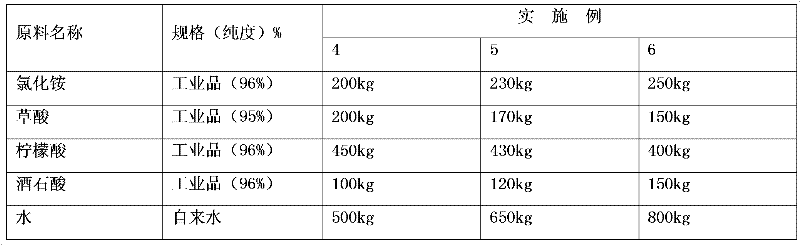

Embodiment 4-6

[0038] Embodiment 4-6: See Table 2 for the raw materials and consumptions used for preparing the composite curing agent:

[0039] Table 2

[0040]

[0041] Preparation method: Taking Example 4 as an example, other examples are the same as Example 4 except for the amount of raw materials.

[0042] Add 200kg of ammonium chloride, 200kg of oxalic acid, 450kg of citric acid, and 100kg of tartaric acid into 500kg of water at 40-50°C in sequence, and stir for 30 minutes to disperse evenly to obtain a composite curing agent.

[0043] Preparation of E0 grade melamine modified urea-formaldehyde resin adhesive:

[0044] The raw materials are as follows: 100 parts by mass of E0 grade melamine modified urea-formaldehyde resin, 15-25 parts by mass of composite filler and 3-5 parts by mass of composite curing agent, slowly add the composite filler into E0-MUF resin, and stir After 15 minutes, add composite curing agent, stir for 20 minutes, and make E0 grade melamine modified urea-for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com