Catalyst for selective hydrogenation of petroleum hydrocarbon and preparation method and application thereof

A catalyst and selective technology are applied in the catalyst for the selective hydrogenation of pyrolysis gasoline, the preparation of the catalyst, the catalyst field in which the metal Ni is the active component, can solve the problems of high cost of the catalyst and the need to improve the stability of the catalyst, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

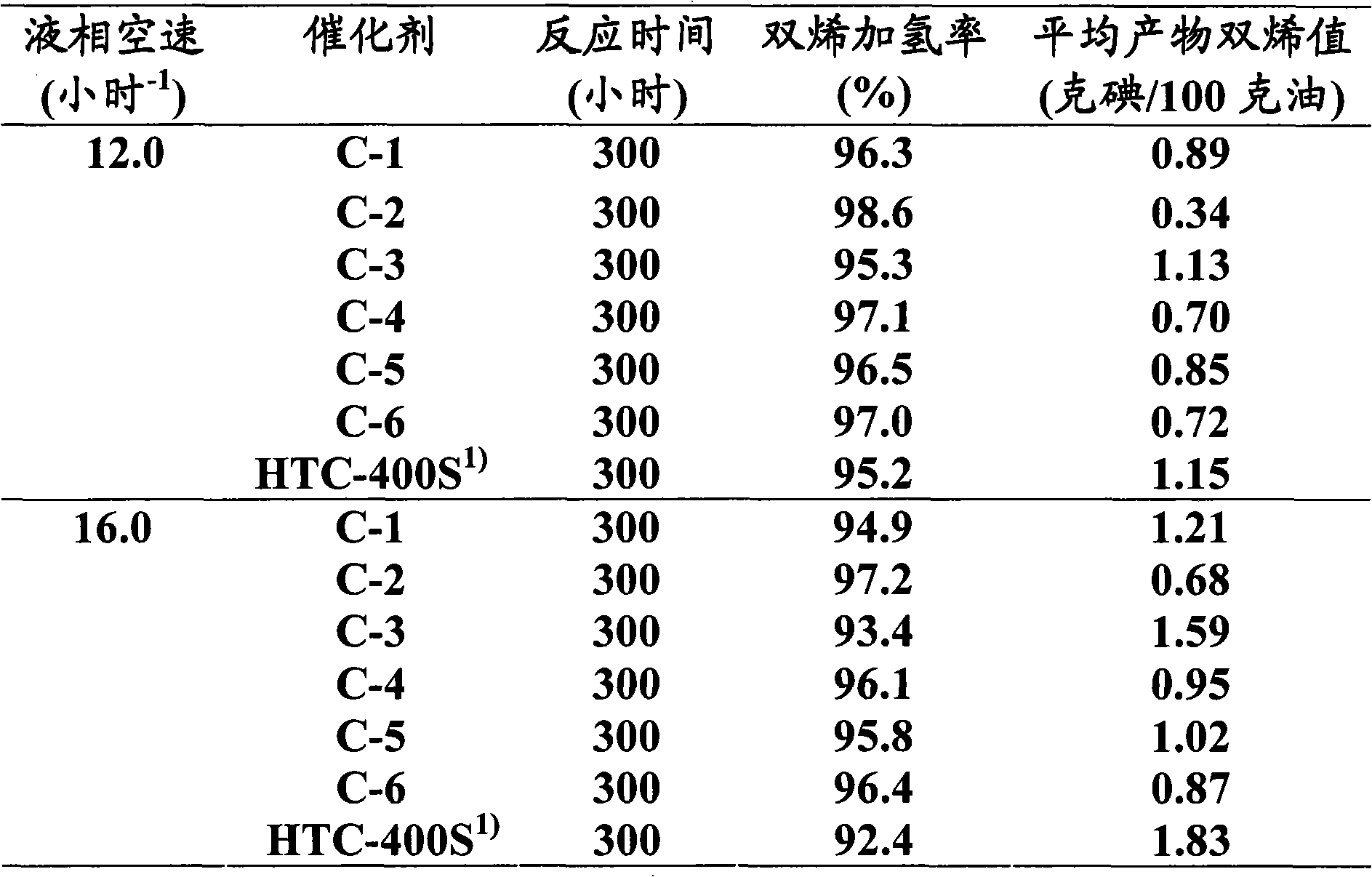

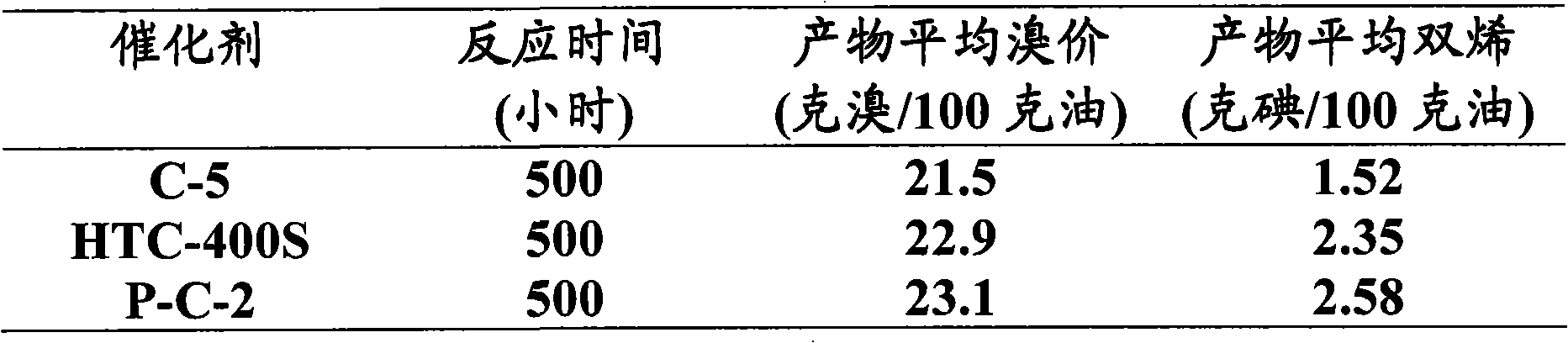

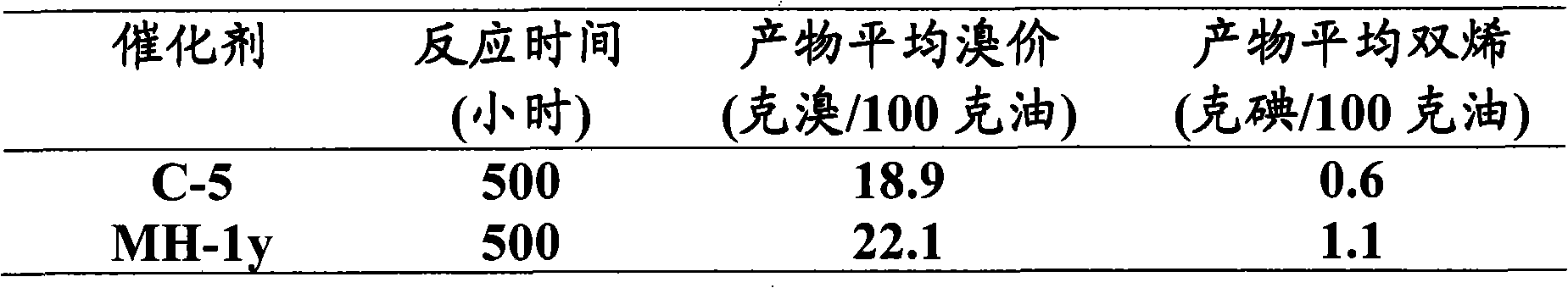

Examples

Embodiment 1

[0042] 1. Preparation of Vectors

[0043] Take TiCl with a concentration of 11.0g / 100ml 4 Aqueous solution 970 milliliters, get the AlCl that concentration is 13.5g / 100ml 3 3450ml aqueous solution, mix the two solutions at room temperature and heat to 80°C, add 6% by weight of ammonia solution under stirring, control the pH value to 9, continue stirring for 20 minutes, and then place the slurry in the oven Settling at 80°C for 30 minutes, filtering the settled slurry; taking out the filter cake, washing and filtering with deionized water 50 times the volume of the filter cake at 60°C, the washing and filtering process Repeat three more times, put the filter cake into the oven for the last time, dry it at 110-120°C for 12 hours, take it out and cool it to room temperature, grind it into powder, extrude it into a clover shape, and roast it at 700°C for 5 hours to obtain 200g of titania-alumina composite carrier A-1 with a specific surface area of 132m 2 / g, the total pore v...

Embodiment 2

[0048] Repeat the preparation process and conditions of the titania-alumina composite carrier A-1 in Example 1, the difference is: take the TiCl with a concentration of 4.07g / 100ml 4 Aqueous solution 700ml with AlCl concentration of 9.42g / 100ml 3 3000 milliliters of aqueous solution were mixed to obtain 100 g of titanium oxide-alumina composite carrier A-2, whose specific surface area was 138 m 2 / g, the total pore volume is 0.38ml / g, the most probable pore diameter is 79 angstroms, and the titania content is 9.98% by weight based on the weight of the titania-alumina composite support.

[0049] Repeat the preparation process and conditions of Ni / titanium oxide-alumina catalyst C-1 in Example 1, the difference is: first get 50 milliliters of nickel nitrate aqueous solutions that are 28.0 g / 100 ml in terms of nickel atoms and impregnate 90 grams of the previous preparation The titania-alumina composite carrier A-2 reaches 35 minutes, blows dry, oven dry, after roasting, obtains...

Embodiment 3

[0051] Repeat the preparation process and conditions of the titania-alumina composite carrier A-1 in Example 1, the difference is: take the TiCl with a concentration of 11.58g / 100ml 4 800 ml of aqueous solution and AlCl with a concentration of 7.94 g / 100 ml 3 3000 milliliters of aqueous solution were mixed to obtain 117 g of titanium oxide-alumina composite carrier A-3, and its specific surface area was 135 m 2 / g, the total pore volume is 0.39ml / g, the most probable pore diameter is 76 angstroms, and the titania content is 29.97% by weight based on the weight of the titania-alumina composite support.

[0052] Repeat the preparation process and conditions of Ni / titania-alumina catalyst C-1 in Example 1, the difference is: first get 50 milliliters of nickel nitrate aqueous solutions that are 12.0 g / 100 ml in terms of nickel atoms and impregnate 80 grams of the previous preparation The titania-alumina composite carrier A-3 reaches 35 minutes, blows dry, dries, roasts and obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com