Pd-Ag/Al2O3-TiO2 catalyst for selective hydrogenation of cracked gasoline or its fractions, and preparation method thereof

A technology for pyrolysis gasoline and catalysts, applied in the direction of metal/metal oxide/metal hydroxide catalysts, through selective hydrotreating, physical/chemical process catalysts, etc., which can solve the problems of catalyst stability and low deactivation rate and other problems, to achieve the effect of stable hydrogenation activity and good gel capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

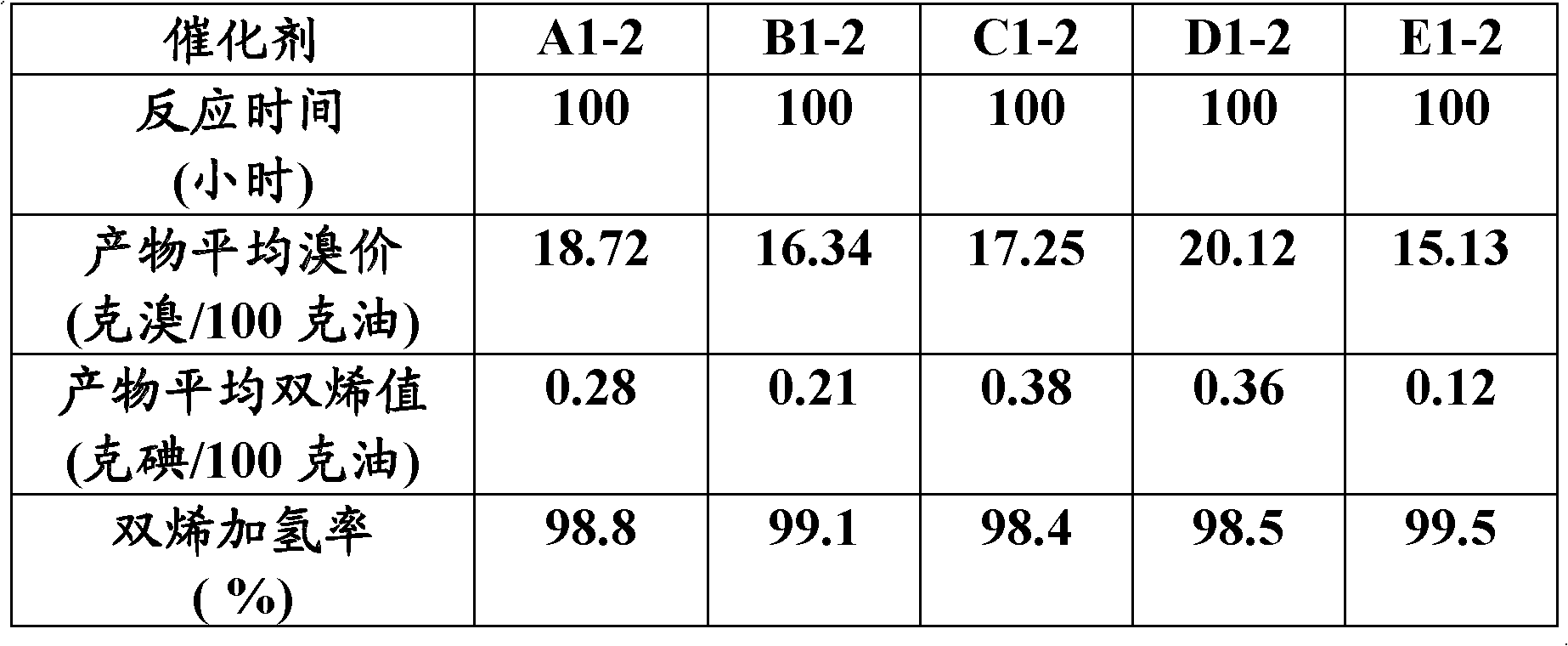

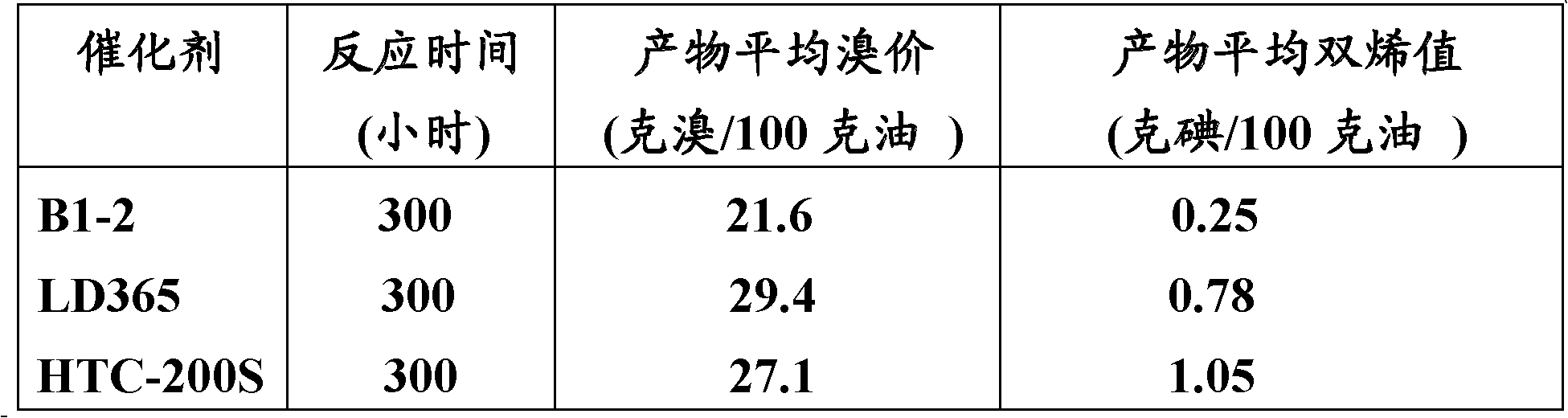

Examples

Embodiment 1

[0037] 1. Preparation of Vector

[0038] Take the specific surface area as 110 meters 2 88 g of clover-shaped alumina with a pore volume of 0.59 ml / g and a most probable pore diameter of 130 angstroms, impregnated with 0.557 g / ml dilute sulfuric acid solution of 65 ml of titanium sulfate, stirred for 15 minutes, and dried at 120°C After 8 hours, it was calcined at 900° C. for 4 hours to obtain a titanium oxide-alumina composite. The composite has a titanium oxide content of 11.87% by weight and a specific surface area of 87 m 2 / g, the pore volume is 0.53 ml / g, and the most probable pore diameter is 123 Angstroms.

[0039] 2. Preparation of catalyst semi-finished products

[0040] Get 100 grams of the titania-alumina composite prepared above, the concentration is Ag 2 O is calculated as 0.97 grams of Ag 2 110 ml of O / 100 ml silver oxalate aqueous solution was poured into the composite carrier, stirred for 20 minutes, allowed to stand for 1.5 hours, drained, and dried at...

Embodiment 2

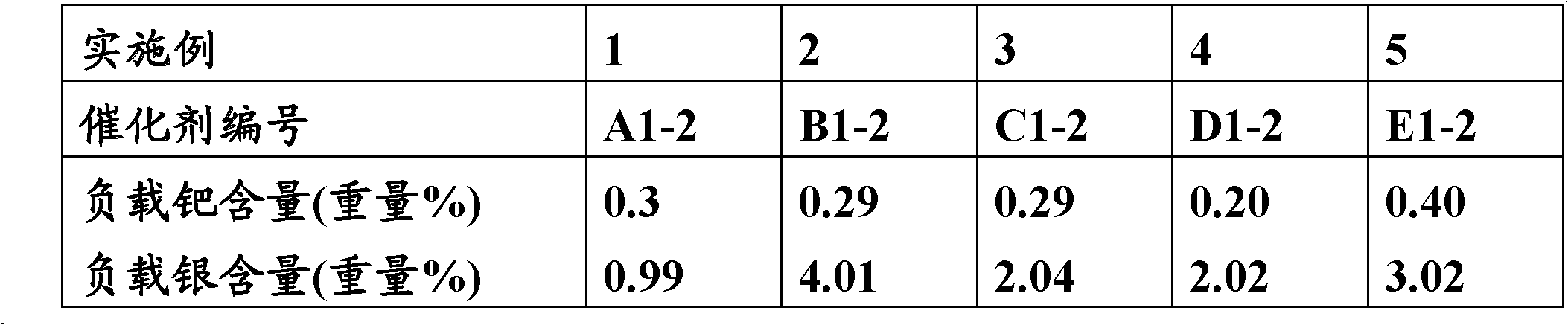

[0044] Repeat Example 1, the difference is: with the concentration of Ag 2 O counted as 3.906 grams of Ag 2 110 milliliters of silver oxalate aqueous solution of 0 / 100ml is impregnated 96 grams of titania-alumina composite carrier, and use concentration is 85 milliliters of palladium chloride aqueous solution of 0.307 gram of palladium / 100ml to impregnate 90 grams of catalyst semi-finished products, make catalyst B1-2, The results are shown in Table 1.

Embodiment 3

[0046] Repeat Example 1, the difference is: with the concentration of Ag 2 O counts as 1.96 grams of Ag 2 110 milliliters of silver oxalate aqueous solution of 0 / 100ml impregnates 98 grams of titania-alumina composite carrier, and use concentration is 0.307 gram palladium / 100ml palladium chloride aqueous solution 85 milliliters impregnates 90 grams of catalyst semi-finished products, makes catalyst C1-2, The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com