A kind of C5 petroleum resin hydrogenation catalyst and preparation method thereof

A hydrogenation catalyst, petroleum resin technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of high energy consumption, hydrogenation reaction temperature and pressure High-level problems, to achieve the effect of high low temperature hydrogenation activity and good resistance to impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

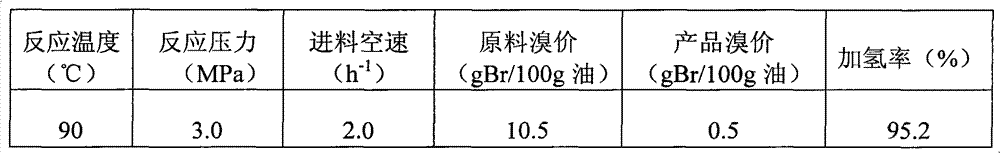

Embodiment 1

[0025] Preparation of carrier: 100g specific surface is 180m 2 / g and clover-type alumina with a pore volume of 0.74ml / g is impregnated with 100ml of titanium sulfate in a 0.8g / ml dilute sulfuric acid solution (wherein the weight concentration of the dilute sulfuric acid aqueous solution is about 10%) for 4 hours at a temperature of 120°C After drying for 10 hours and calcining at 700° C. for 6 hours, 126.7 g of alumina-titania composite carrier 1 was obtained, wherein the weight ratio of alumina to titania was 4:1.

[0026] The preparation of catalyst: the composite carrier 1 that 100g pore volume is 0.72ml / g is immersed in 85ml containing palladium chloride 0.51g / ml and in the mixed aqueous solution containing ammonium molybdate 0.006g / ml, after immersion 4 hours, drain moisture, It was reduced with 120ml of 40% hydrazine hydrate for 2 hours, washed with deionized water until there were no chloride ions, then dried at 110°C for 5 hours, and calcined at 700°C for 6 hours to o...

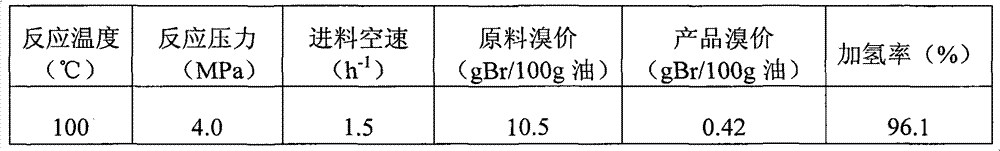

Embodiment 2

[0030] Preparation of the carrier: the specific surface area of 180g is 178m 2 / g and clover-type alumina with a pore volume of 0.76ml / g was impregnated with 142ml of cyclohexane solution containing tetraethyl titanate 1.25g / ml for 4 hours, dried at 110°C for 6 hours, and then dried at 700°C Calcined at high temperature for 5 hours; 240 g of alumina-titania composite carrier was obtained, wherein the weight ratio of alumina and titania was 3:1.

[0031] The preparation of catalyst: the composite carrier 2 that 120g pore volume is 0.72ml / g is immersed in 92ml containing palladium chloride 0.64g / ml and in the mixed aqueous solution containing ammonium molybdate 0.007g / ml, after 5 hours of immersion, drain moisture, It was reduced with 120ml of 40% hydrazine hydrate for 2 hours, washed with deionized water until there was no chloride ion, then dried at 110°C for 4 hours, and calcined at 700°C for 6 hours to obtain the catalyst. Wherein the content of palladium is 0.28% of the ...

Embodiment 3

[0033] Preparation of carrier: 175g specific surface is 180m 2 / g and a clover-type alumina with a pore volume of 0.74ml / g was impregnated with 135ml of tetraethyl titanate in a 0.62g / ml cyclohexane solution for 4 hours, dried at a temperature of 120°C for 9 hours, and then dried at a temperature of 500°C Calcined at the bottom for 6 hours to obtain 205 g of alumina-titania composite carrier, wherein the weight ratio of alumina to titania is 6:1.

[0034] Catalyst preparation: immerse 120g of composite carrier 1 with a pore volume of 0.72ml / g into 96ml of a mixed aqueous solution containing palladium chloride 0.64g / ml and ammonium metatungstate 0.005g / ml, and after immersion for 6 hours, drain the water , reduced with 120ml of 40% hydrazine hydrate for 2 hours, washed with deionized water until no chloride ions were present, dried at 120°C for 6 hours, and calcined at 600°C for 7 hours to obtain a catalyst. Wherein the content of palladium is 0.3% of the total weight of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com