A kind of selective hydrogenation catalyst and its preparation method and application

A technology for selective hydrogenation and catalysts, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc. improvement etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

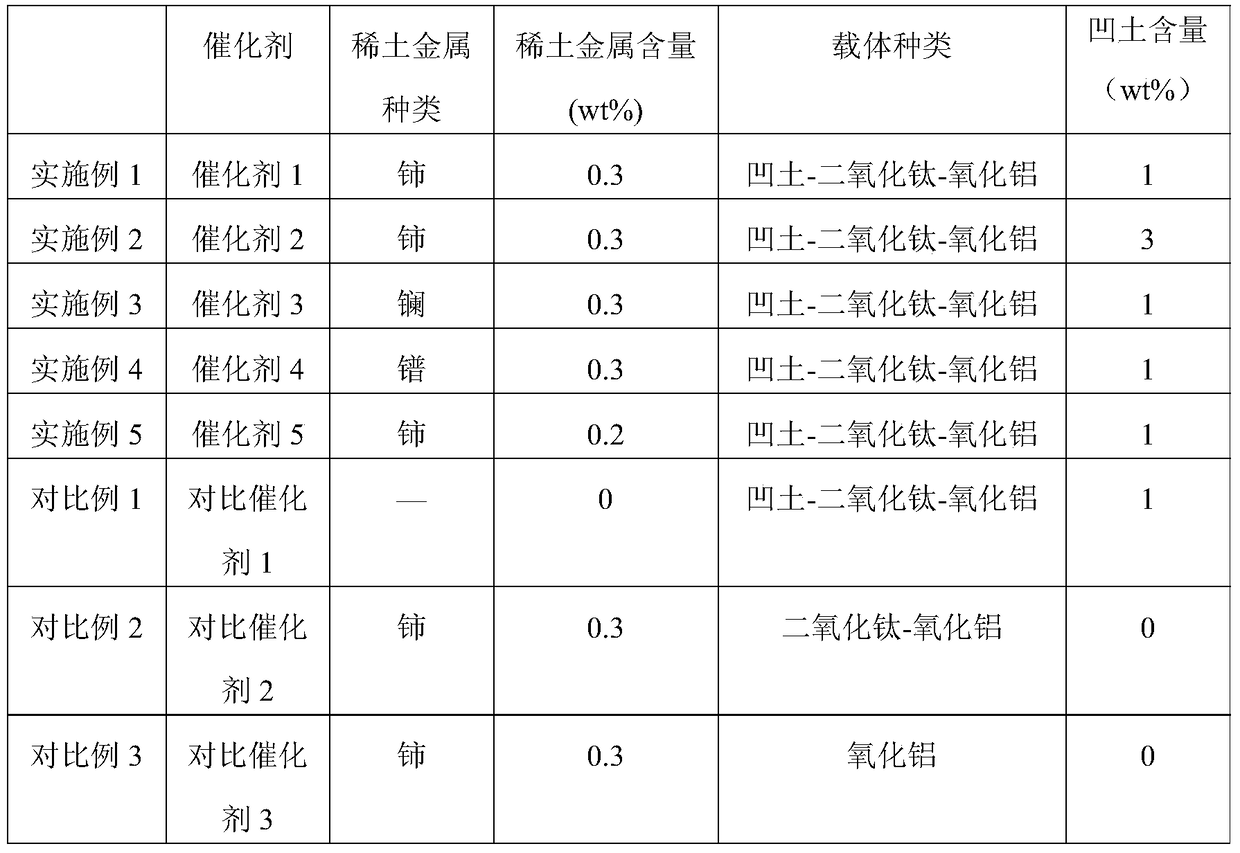

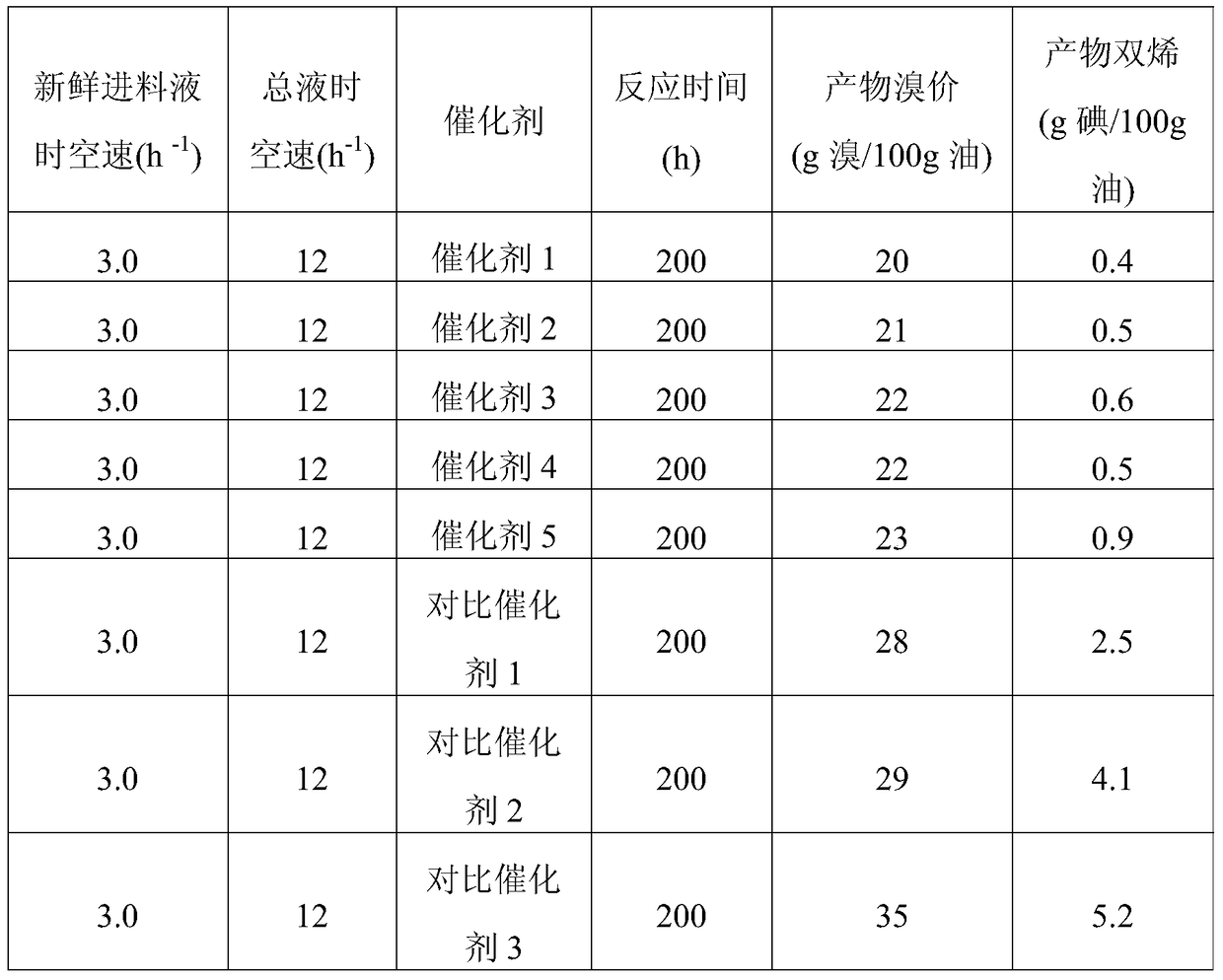

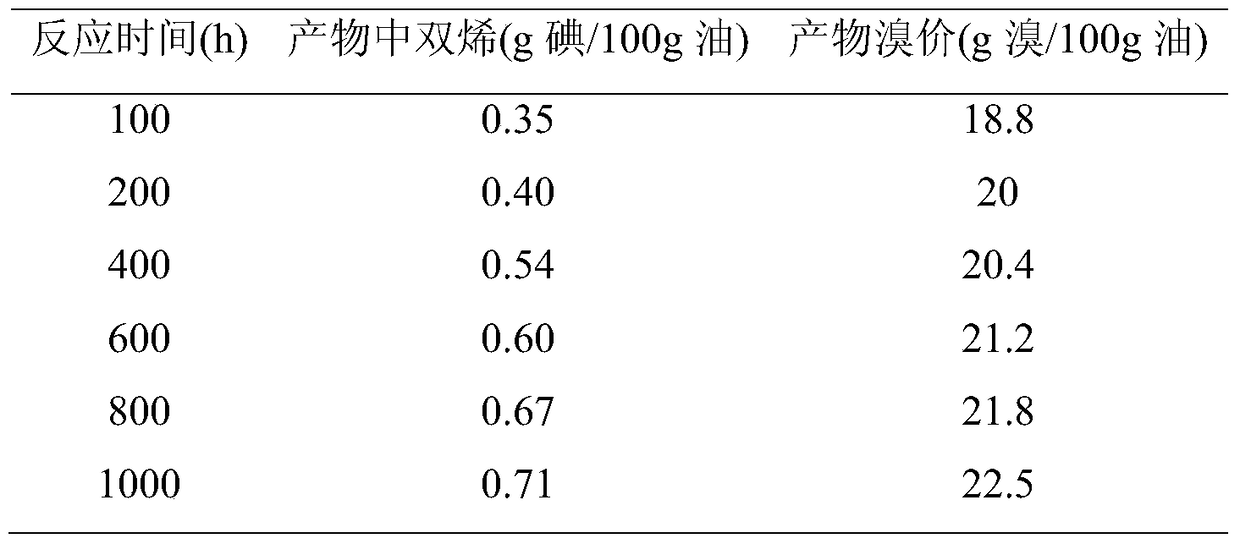

Embodiment 1

[0066] step 1

[0067] (1) Using TiCl 4 Prepare 0.25mol / L TiCl with deionized water 4 aqueous solution;

[0068] (2) Using Al(NO 3 ) 3 9H 2 O crystal and deionized water prepare the aluminum nitrate aqueous solution of 1.55mol / L;

[0069] (3) use attapulgite and deionized water to prepare the attapulgite aqueous solution of 10g / L;

[0070] (4) According to Al 2 o 3 weight of TiCl 4 with TiO 2 The content of meter is 20% by weight and the attapulgite content is the amount of 1% by weight, solution A, B and C are mixed, obtain the mixed solution containing attapulgite, Ti and Al;

[0071] (5) Using the co-current co-precipitation method, in a constant temperature water bath at 40°C, 0.5mol / L (NH 4 ) 2 CO 3 Aqueous solution and prepared mixed solution containing attapulgite, Ti and Al, wherein the dropping rate of mixed solution is 60 drops / min, (NH 4 ) 2 CO 3 The dropping rate of the aqueous solution is 30 drops / min; after the dropwise addition is completed, adju...

Embodiment 2

[0079] Repeat the steps 1-3 of embodiment 1, difference is: in the sub-step (4) of step 1, according to based on aluminum nitrate with Al 2 o 3 weight of TiCl 4 with TiO 2 The content of the attapulgite is 20% by weight, and the content of attapulgite is 3% by weight. Solutions A, B and C are mixed to obtain a mixed solution containing attapulgite, Ti and Al.

[0080] As a result, in the attapulgite-titania-alumina composite oxide support obtained in Step 1, the content of attapulgite was 3% by weight based on the weight of alumina, and TiO 2 The content of is 20% by weight; and the specific surface area of the carrier is 122m 2 / g, the most probable pore diameter is 17nm, and the pore volume is 0.50ml / g.

[0081] As a result, palladium-based catalyst 2 was obtained through step 3. The palladium content of the palladium-based catalyst 2 is 0.3% by weight, the cerium content is 0.3% by weight, and the crushing strength is 21 N / mm; in the carrier of the catalyst, the cont...

Embodiment 3

[0083] Steps 1-3 of Example 1 were repeated, except that the impregnation solution used in step 2 for impregnating the composite carrier was replaced with 90 ml of 0.2 mol / L lanthanum nitrate aqueous solution.

[0084] As a result, palladium-based catalyst 3 was finally obtained. Palladium-based catalyst 3 has a palladium content of 0.3% by weight, a lanthanum content of 0.3% by weight, and a crush strength of 21 N / mm; in the carrier of the catalyst, the content of attapulgite is 1% by weight based on the weight of alumina, TiO 2 The content based on the weight of alumina is 20% by weight; and the specific surface area of the carrier is 128m 2 / g, the most probable pore diameter is 18nm, and the pore volume is 0.52ml / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com