Hydrogenation catalyst for C5 petroleum resin, and preparation method and application thereof

A petroleum resin and catalyst technology, which is applied in the field of C5 petroleum resin hydrogenation catalyst and its preparation, to achieve the effects of high low-temperature hydrogenation activity, good resistance to impurities and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

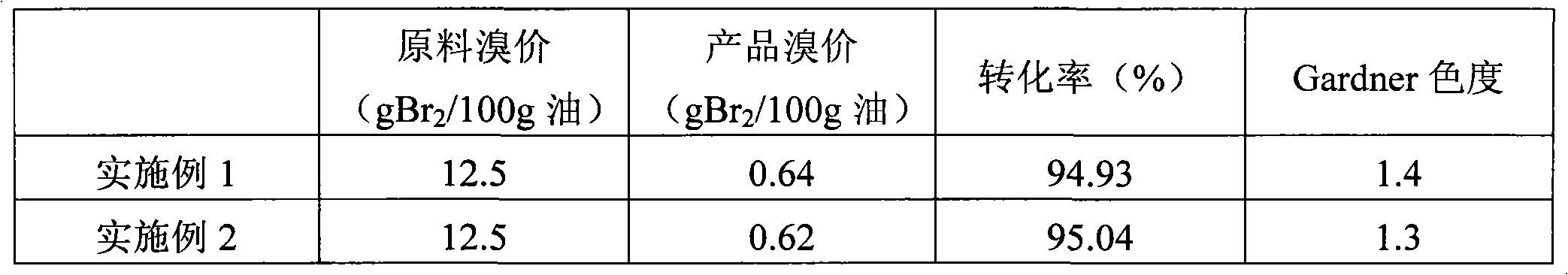

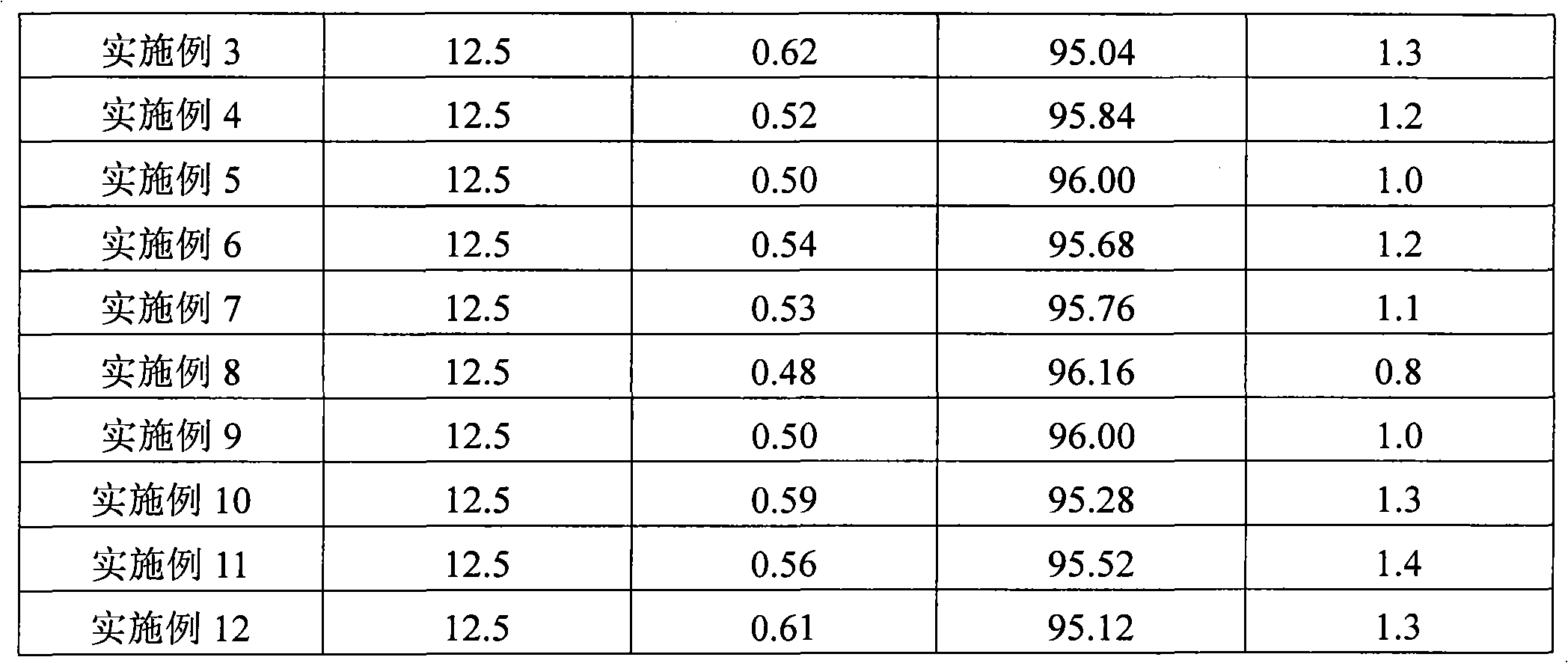

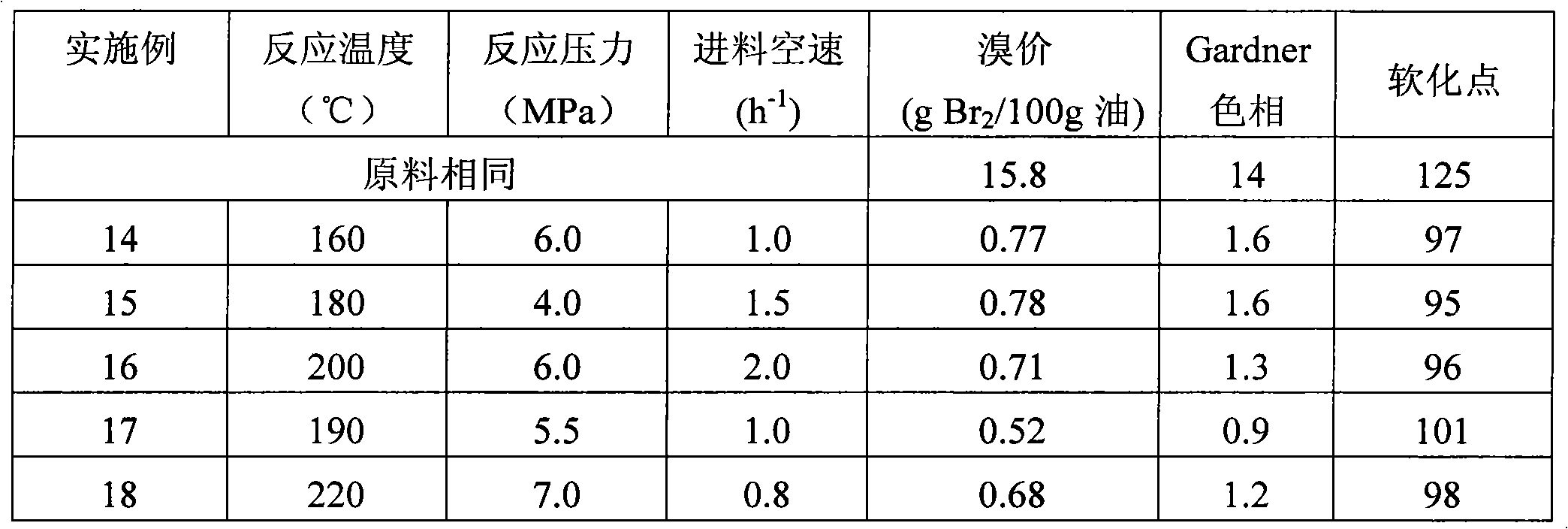

Examples

Embodiment 1

[0029] Preparation of the carrier: the specific surface area of 180g is 178m 2 / g and clover-shaped alumina with a pore volume of 0.76ml / g was impregnated with 142ml cyclohexane solution containing tetraethyl titanate 1.25g / ml for 4 hours, dried at 110°C for 6 hours, and then dried at 700°C Calcined at high temperature for 5 hours; 240 g of alumina-titania composite carrier was obtained, wherein the weight ratio of alumina and titania was 3:1.

[0030] Preparation of the catalyst: Add 3.44g of nickel nitrate into 5mL of water, stir to dissolve, add 1.31g of magnesium nitrate under stirring, adjust the pH value to 5 with dilute nitric acid, immerse 10g of alumina-titania composite carrier in it for 3 hours, The impregnated composite support was filtered off, dried at 110°C for 6 hours, and calcined at 600°C for 5 hours. 11.76 g of Catalyst 1A were obtained with a specific surface area of 156 m 2 / g, the pore volume is 0.58ml / g. The content of nickel oxide is 12% based on...

Embodiment 2

[0033] Preparation of the catalyst: Add 3.54g of nickel nitrate to 5mL of water, stir to dissolve, add 2.24g of magnesium nitrate under stirring, adjust the pH value to 5 with dilute nitric acid, immerse 10g of alumina-titania composite carrier in it for 4 hours, The impregnated composite support was filtered off, dried at 120°C for 5 hours, and calcined at 500°C for 7 hours. 12.1 g of catalyst 1B were obtained with a specific surface area of 160 m 2 / g, the pore volume is 0.61ml / g. The content of nickel oxide is 12% based on the weight of the catalyst, and the content of magnesium oxide is 5% based on the weight of the catalyst.

Embodiment 3

[0035] Catalyst preparation: Add 3.62g of nickel nitrate to 5mL of water, stir to dissolve, add 2.03g of copper nitrate under stirring, adjust the pH value to 4 with dilute nitric acid, immerse 10g of alumina-titania composite carrier in it for 4 hours, The impregnated composite support was filtered off, dried at a temperature of 110°C for 6 hours, and calcined at a temperature of 600°C for 6 hours. Obtained 12.35g catalyst 1C, its specific surface area is 162m 2 / g, the pore volume is 0.62ml / g. The content of nickel oxide is 12% based on the weight of the catalyst, and the content of copper oxide is 7% based on the weight of the catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com