Selective hydrogenation catalyst and its preparation method and application

A hydrogenation catalyst and selective technology, applied in the field of selective hydrogenation catalyst and its preparation, can solve the problems of insignificant increase in selectivity, accelerated carbon and coke deposition, unsuitable high hydrogenation activity, etc., to achieve a large theory Effects of specific surface area, extended regeneration period, and multiple active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] First, the prepared graphene was washed with 10% nitric acid for 3 hours, then washed with water until neutral, then soaked in 2% dilute ammonia water for 1 hour, and dried at 120° C. for 5 hours to obtain the graphene carrier.

[0030] The preparation of Pd / graphene (0.5% by weight): the palladium chloride of metering is dissolved in pure water, hydrochloric acid is added dropwise to all dissolving and the pH value of solution is adjusted to 3 while heating, and above-mentioned treated graphite Graphene is impregnated in the prepared palladium chloride solution by metering, and after soaking for 12 hours, it is dried at 120° C. to prepare a supported graphene catalyst precursor.

[0031] Prepare the supported graphene catalyst precursor of Pd / graphene (0.3% by weight), Pd / graphene (0.2% by weight) in the same way.

Embodiment 2

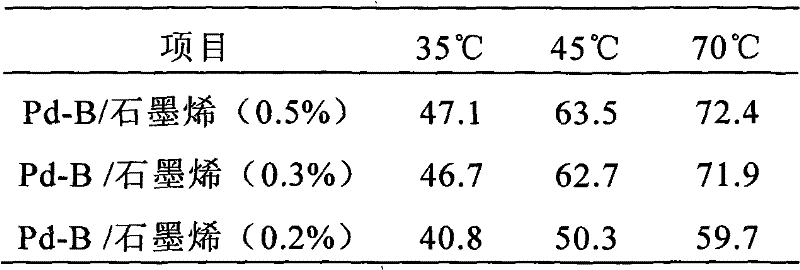

[0033] Three kinds of catalyst precursors prepared by Example 1 were reduced by electroless plating to obtain Pd / graphene catalysts with different active metal contents. The specific method is:

[0034] Put the Pd / graphene catalyst precursor into a three-necked flask with an ice-water bath, and after passing through nitrogen, add metered KBH dropwise 4 -KOH mixed solution reduction, until there is no gas release in the system, the black solid Pd-B / graphene catalyst obtained. After repeated washing with distilled water, they were stored in absolute ethanol for later use.

Embodiment 3

[0036] The three catalyst precursors prepared in Example 1 were subjected to hydrogen reduction to obtain Pd / graphene catalysts with different active metal contents. The specific method is:

[0037] The Pd / graphene catalyst precursor is directly put into a tubular reactor, and the Pd / graphene catalyst is obtained by passing hydrogen gas at 120° C. for 3 to 5 hours for reduction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com