Full-cut fraction pyrolysis gasoline diolefin selective hydrogenation method

A technology for pyrolysis gasoline and selective hydrogenation, which is applied in the field of selective hydrotreating of medium and low distillates, can solve the problems of bearing hydrogenation load and poor hydrogenation stability, and achieves good hydrogenation stability performance and excellent hydrogenation stability. Performance, strong resistance to impurities and the effect of anti-glue ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

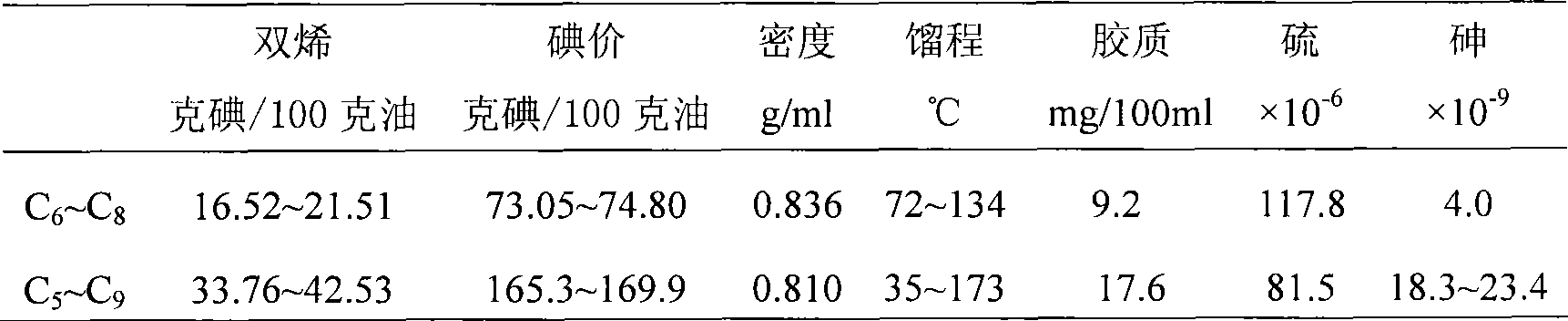

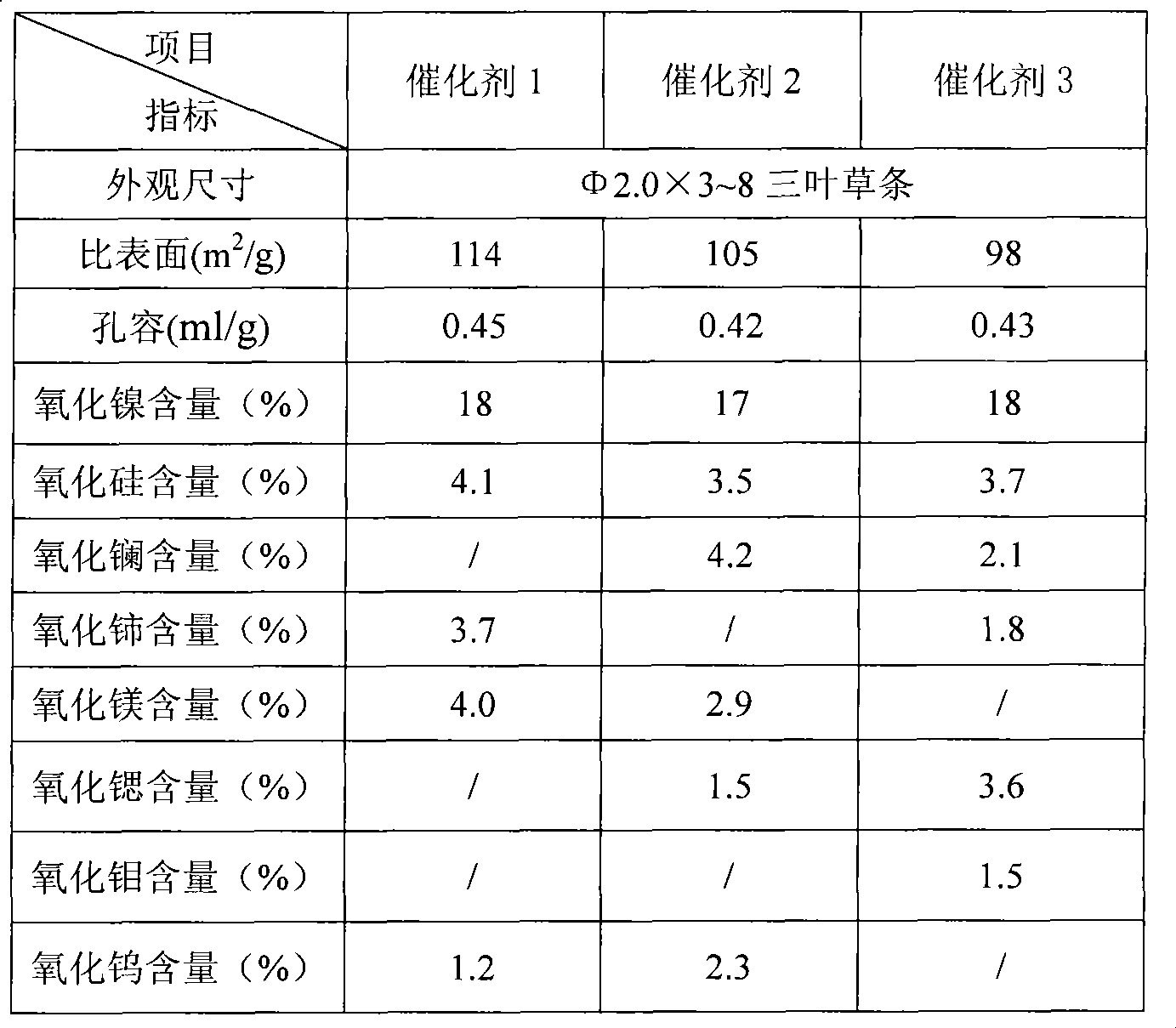

[0026] Preparation of catalysts 1-3:

[0027] Add 140ml of water, 5ml of nitric acid (content 60%), and silica sol (containing 40% of silicon dioxide) to 300g of pseudo-boehmite alumina powder, knead and extrude into strips, and dry at 120°C in the air at 350- Bake at 560°C for 3 to 6 hours. Take 100 g of the roasted carrier, then dissolve magnesium nitrate and / or strontium nitrate into water according to the required amount, impregnate the carrier, dry at 120 °C in the air, and roast at 800 to 1100 °C to obtain the corresponding modification. Al 2 O 3 vector.

[0028] Add nickel nitrate to 20ml~30ml of water, stir and dissolve, add cerium and / or lanthanum, soluble salt of VIB element in the stirring according to the required amount, adjust the pH value to 4, then immerse it on 10g carrier, age for 12 hours, The catalyst was prepared by drying at 120°C and calcining at 400°C for 4 hours. The physicochemical properties of the obtained catalysts are shown in Table 2.

[00...

Embodiment 1

[0032] The catalyst 1 was loaded into a 100ml adiabatic bed hydrogenation reaction device, and under the condition of a pressure of 0.5MPa, the bed was heated to 240°C at a rate of 50°C / h and maintained for 5h, and then heated to 360°C at a rate of 10°C / h. ℃, maintained for 10h, then heated to 410℃ at a rate of 15℃ / h, maintained for 5h; then cooled to 50℃, put in cyclohexane containing 1000ppm of dimethyl disulfide, and continued to run for 3h. with C 5 ~C 9 Whole distillate oil is used as raw material, at reaction pressure: 2.8MPa, inlet temperature: 60℃, fresh raw material oil space velocity: 3h -1 , hydrogen and oil volume ratio: 200:1 (volume ratio is based on fresh oil) under the condition of running for 200h. The average diene of the hydrogenation product within 200 hours was 0.82 g iodine / 100 g oil, and the iodine value was 35.6 g iodine / 100 g oil.

Embodiment 2

[0034] The catalyst 1 was loaded into a 100ml adiabatic bed hydrogenation reactor, and under the condition of a pressure of 0.5MPa, the bed was heated to 260°C at a rate of 65°C / h and maintained for 6h, and then heated to 350°C at a rate of 12°C / h. ℃, maintained for 11h, then heated to 390℃ at a rate of 12℃ / h, maintained for 4h; then cooled to 60℃, put in cyclohexane containing 2000ppm of dimethyl disulfide, and continued to run for 2h. with C 5 ~C 9 Whole distillate oil is used as raw material, at reaction pressure: 2.8MPa, inlet temperature: 70℃, fresh raw material oil space velocity: 2.8h -1 , hydrogen and oil volume ratio: 200:1 (volume ratio is based on fresh oil) under the condition of running for 400h. The average diene of the hydrogenation product within 400 hours was 0.81 g iodine / 100 g oil, and the iodine value was 36.9 g iodine / 100 g oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| olefinic | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com