a ni 2 Preparation method of p/nc catalyst, ni2p/nc catalyst and its application

A catalyst and cyclohexane technology, applied in the preparation of organic compounds, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as unsuitable for large-scale production, low conversion rate of reactants, low product selectivity, etc. , to achieve good hydrogenation effect, low requirements for reaction equipment, and high reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

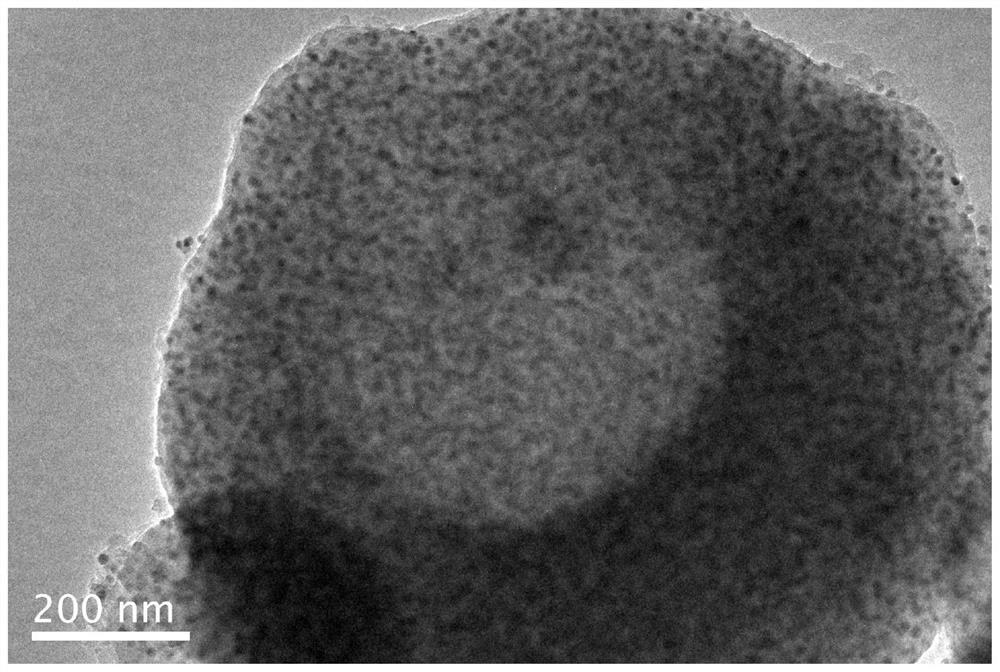

[0036] Ni in this example 2 The preparation method of P / NC catalyst comprises the following steps:

[0037] 1) 400ml of a mixed solution composed of absolute ethanol and water at a volume ratio of 1:1, add the above mixed solution to the agitator, adjust the speed of the agitator to 500r / min, stir, add 5g of polyoxyethylene polyoxypropylene The ether block copolymer was continued to stir for 1 h; then 2.5 g of dopamine was added and continued to stir for 2 h, and 2.5 g of nickel nitrate hexahydrate was weighed, added to the above solution and continued to stir for 2 h; adding concentration was 6 ml of hydrochloric acid of 12 mol / l, and stirred for 2 h; Then slowly drop (two drops per second) 10ml of mesitylene, stir for 4h, take 25mL of ammonia water with a concentration of 6mol / l, drop by drop (one drop per second) into the above solution, and continue stirring for 4h; finally perform centrifugation, The precipitate after centrifugation was alternately washed five times with...

Embodiment 2

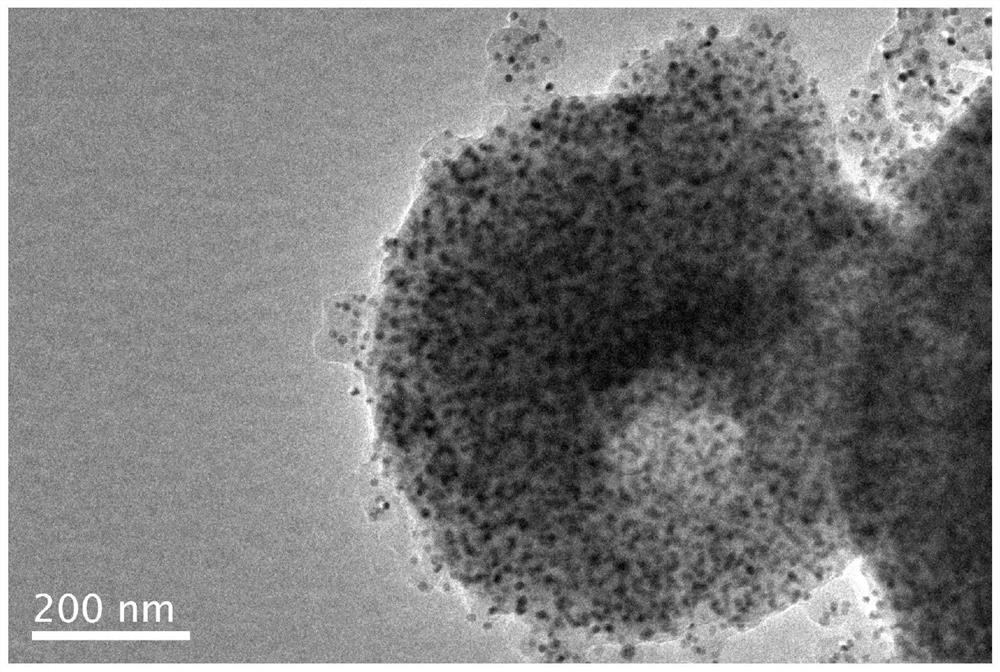

[0043] Ni in this example 2 The preparation method of P / NC catalyst comprises the following steps:

[0044] 1) 400ml of a mixed solution composed of absolute ethanol and water at a volume ratio of 1:1, add the above mixed solution into the agitator, adjust the speed of the agitator to 500r / min, stir, add 5g of polyoxyethylene polyoxypropylene Continue to stir the ether block copolymer for 1 hour; then add 2.5 g of dopamine and continue to stir for 2 hours, weigh 1.5 g of nickel nitrate hexahydrate, add the above solution and continue to stir for 2 hours; then add 6 ml of hydrochloric acid with a concentration of 12 mol / l, and stir for 2 hours; Slowly drop (two drops per second) 10ml of mesitylene, stir for 4 hours, take 25ml of ammonia water with a concentration of 6mol / l, drop by drop (one drop per second) into the above solution, and continue stirring for 4 hours; 70% ethanol aqueous solution and absolute ethanol were used to alternately wash the precipitate after centrifug...

Embodiment 3

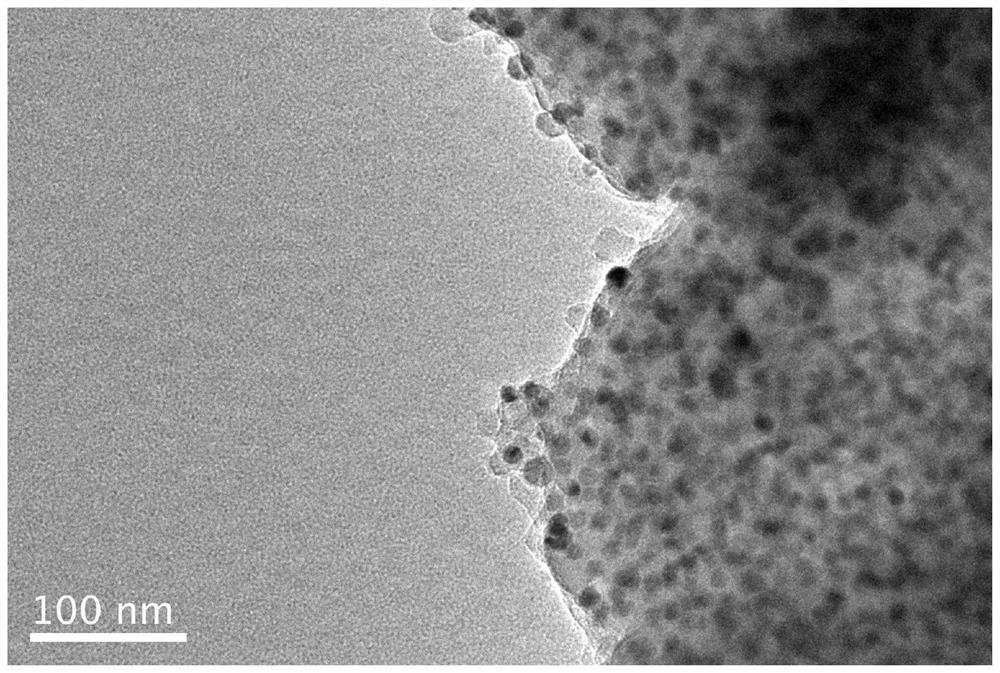

[0050] Ni in this example 2 The preparation method of P / NC catalyst comprises the following steps:

[0051] 1) 600ml of a mixed solution composed of absolute ethanol and water at a volume ratio of 2:1, add the above mixed solution to the agitator, adjust the speed of the agitator to 300r / min, stir, add 5g of polyoxyethylene polyoxypropylene Continue to stir the ether block copolymer for 1h; then add 1g of dopamine and continue to stir for 2h, weigh 4g of nickel nitrate hexahydrate, add the above solution and continue to stir for 2h; then add 6ml of hydrochloric acid with a concentration of 12mol / L, stir for 2h; then slowly drop Add (two drops per second) 10ml of mesitylene, stir for 4 hours, take 25ml of ammonia water with a concentration of 6mol / L, drop by drop (one drop per second) into the above solution, and continue stirring for 3 hours; finally, perform centrifugation and use 70% The ethanol aqueous solution and absolute ethanol were used to alternately wash the precipi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com