Saturation and hydrogenation method of C9 fraction through cracking by petroleum hydrocarbons

A technology for cracking carbon and petroleum hydrocarbons, which is applied in the field of hydrogenation of alkynes, dienes, and monoolefins into corresponding alkanes in the cracking of carbon nine fractions of petroleum hydrocarbons, which can solve the problem that dienes do not have hydrogenation selectivity, etc., and achieve The effect of mild operating conditions, good water resistance, and increased added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

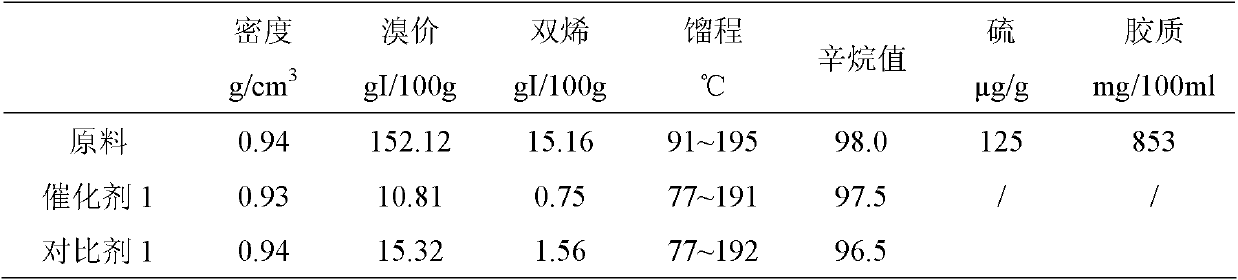

Embodiment 1

[0041] Dissolve 200g of sodium carbonate and 38g of ammonium bicarbonate in 1000ml of water to make a precipitant; 212g of nickel nitrate, 30g of aluminum nitrate, 28g of sodium metaaluminate, 5g of magnesium nitrate, 6.6g of zirconium nitrate, 1.7g of copper nitrate, and 16.8g of molybdenum Dissolve ammonium nitrate, 3g of lanthanum nitrate, and 15g of sodium stannate in 800ml of water, heat to 55°C, add a precipitant, and then add 30g of diatomaceous earth after all the precipitant is added. Continue heating to 90°C, adjust the pH value to 8.6 with potassium carbonate, and stir for 1 h. After filtration, the filter cake was washed 5 times with distilled water. The filter cake was dried and extruded into a cylindrical shape of Φ3×8mm to obtain the catalyst precursor 1. In a 100ml fixed-bed reactor, under a hydrogen atmosphere, reduce the catalyst precursor 1 at a reduction temperature of 380°C for 24 hours, cool down to 80°C, pass nitrogen to cool to 30°C, stop nitrogen flow...

Embodiment 2

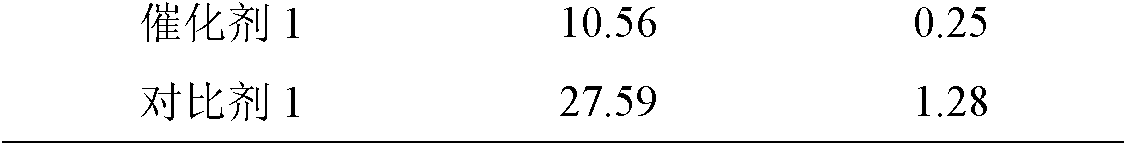

[0054] Dissolve 200g of sodium carbonate and 38g of ammonium bicarbonate in 1000ml of water to make a precipitant; 221g of nickel nitrate, 30g of aluminum nitrate, 28g of sodium metaaluminate, 15g of magnesium nitrate, 3.4g of copper nitrate, 7.5g of ammonium molybdate, and 6g of nitric acid Dissolve lanthanum and 9.9g sodium stannate in 800ml water, heat to 55°C, add a precipitating agent, and then add 30g diatomaceous earth after all the precipitating agent is added. Continue heating to 90°C, adjust the pH value to 8.8 with potassium carbonate, and stir for 1 h. After filtration, the filter cake was washed 5 times with distilled water. The filter cake was dried and extruded into a cylindrical shape of Φ3×8mm to obtain the catalyst precursor 2. In a 100ml fixed-bed reactor, under a hydrogen atmosphere, reduce the catalyst precursor 2 at a reduction temperature of 350°C for 28 hours, cool down to 90°C, cool down to 35°C with nitrogen, stop nitrogen, and increase air Measure ...

Embodiment 3

[0067] Dissolve 200g sodium carbonate and 38g ammonium bicarbonate in 1000ml water to make a precipitant; 230g nickel nitrate, 30g aluminum nitrate, 28g sodium metaaluminate, 15g magnesium nitrate, 9g zinc nitrate, 5g zirconium nitrate, 7.5g ammonium molybdate 1. Dissolve 9.9g of sodium stannate in 800ml of water, heat to 55°C, add a precipitating agent, and then add 30g of diatomaceous earth after all the precipitating agent is added. Continue heating to 90°C, adjust the pH value to 9 with potassium carbonate, and stir for 1 h. After filtration, the filter cake was washed 5 times with distilled water. The filter cake was dried and extruded into a cylindrical shape of Φ3×8 mm to obtain the catalyst precursor 3 . In a 100ml fixed-bed reactor, under a hydrogen atmosphere, the catalyst precursor 3 was reduced at a reduction temperature of 440° C. for 15 hours, and the temperature was lowered to 100° C. Cool the temperature down to 35°C by blowing nitrogen, stop blowing nitrogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com