Method for deep desulfurization olefin hydrocarbon reduction of gasoline

A deep desulfurization and olefin technology, applied in refining to remove heteroatoms, etc., can solve the problems of high olefin saturation rate, large loss of octane number, and inability to handle olefin content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

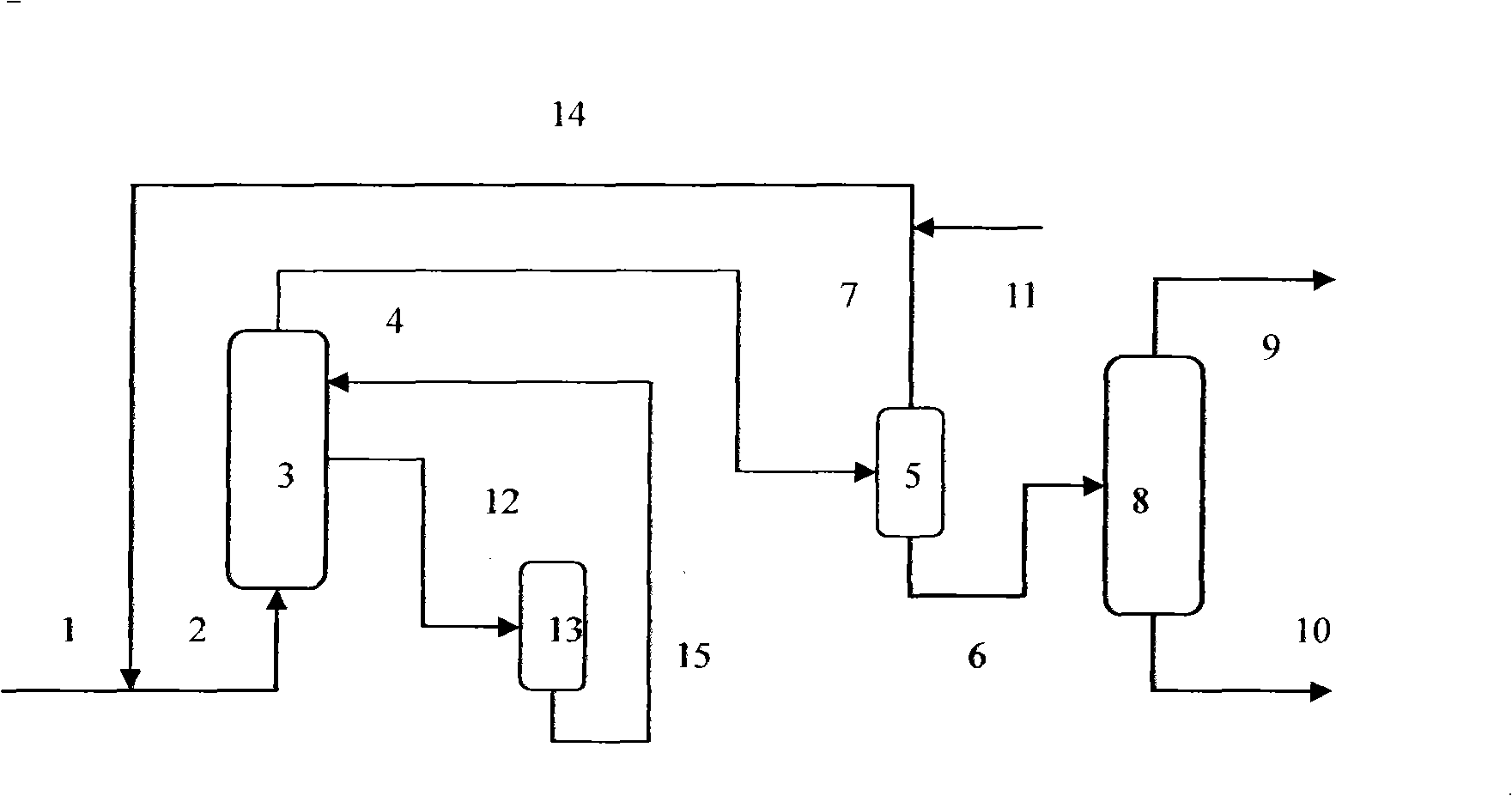

Image

Examples

Embodiment 1

[0033] Compared with the comparative example, under the condition of the same raw materials, the mixture of gasoline fraction, hydrogen and hydrogenation adsorption catalyst and olefin aromatization catalyst is contacted to carry out hydrodesulfurization reaction and olefin aromatization reaction. Process conditions and product properties are shown in Table 2. It can be seen from Table 2 that the sulfur content of the gasoline fraction is 45 μg / g, the olefin content is 19.0 v%, and the antiknock index (RON+MON) / 2 has decreased by 0.5 units.

Embodiment 2

[0035] Using FCC gasoline B as raw material, the mixture of gasoline fraction, hydrogen and hydrogenation adsorption catalyst and olefin aromatization catalyst are contacted to carry out hydrodesulfurization reaction and olefin aromatization reaction. Process conditions and product properties are shown in Table 2. It can be seen from Table 2 that the gasoline fraction has a sulfur content of 18 μg / g, an olefin content of 19.1 v%, and an antiknock index (RON+MON) / 2 decreased by 0.4 units.

Embodiment 3

[0037] Using FCC gasoline C as raw material, the mixture of gasoline fraction, hydrogen and hydrogenation adsorption catalyst and olefin aromatization catalyst are contacted to carry out hydrodesulfurization reaction and olefin aromatization reaction. Process conditions and product properties are shown in Table 3. As can be seen from Table 2, the sulfur content of the gasoline fraction is 3 μg / g, the olefin content is 19.2v%, and the antiknock index (RON+MON) / 2 has decreased by 0.3 units.

[0038] Table 1 Main properties of gasoline raw materials used in the examples

[0039] raw material A

raw material B

raw material C

Density (20℃), g / cm 3

0.7133

0.7155

0.7240

Sulfur content, μg / g

900

900

680

Olefin content, v%

37

40

41

Aromatic content, v%

16

15

16

Distillation range, ℃

initial boiling point

42

41

38

10%

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com