Pyrolysis gasoline cut fraction section selective hydrogenation method

A pyrolysis gasoline and selective technology, which is applied in the field of one-stage selective hydrogenation of pyrolysis gasoline fractions, can solve the problems of small pore volume, easy coking and clogging of the pores on the catalyst, affecting the hydrogenation stability of the catalyst, etc., and achieves good hydrogenation performance, The effect of good hydrogenation activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

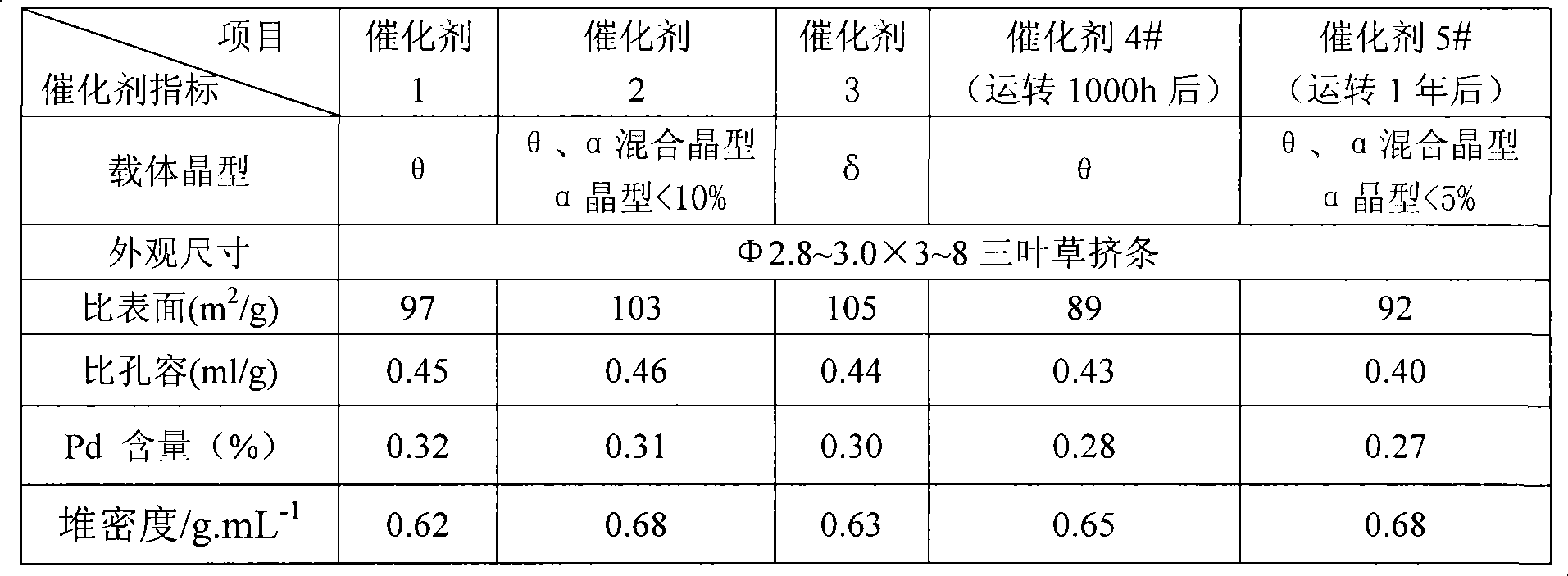

[0027] The preparation of catalyst 1~5:

[0028] ① Add 180ml of water to 300g of alumina powder, knead and extrude to shape, dry in the air at 120°C, bake at 560°C for 4 hours, then weigh a certain amount of lanthanum nitrate and / or cerium nitrate, alkaline earth metal The nitrate is dissolved in water, impregnated on the carrier, dried in the air at 120°C, and roasted at 850-1100°C for 4-6 hours to obtain modified Al 2 o 3 carrier.

[0029]Weigh a certain amount of palladium chloride powder with a palladium content of not less than 59%, add 200ml of water, then add hydrochloric acid, dissolve and dilute to 1-1.2L with deionized water, adjust the pH value according to the required shell thickness; Take 1.0kg of the finished carrier, add deionized water to pre-soak the carrier, and then filter the water; pour the prepared palladium chloride solution onto the carrier, filter the water after 20 minutes, dry at 120°C, and roast at 400-450°C for 4 Hours, fresh catalysts 1, 2, 3,...

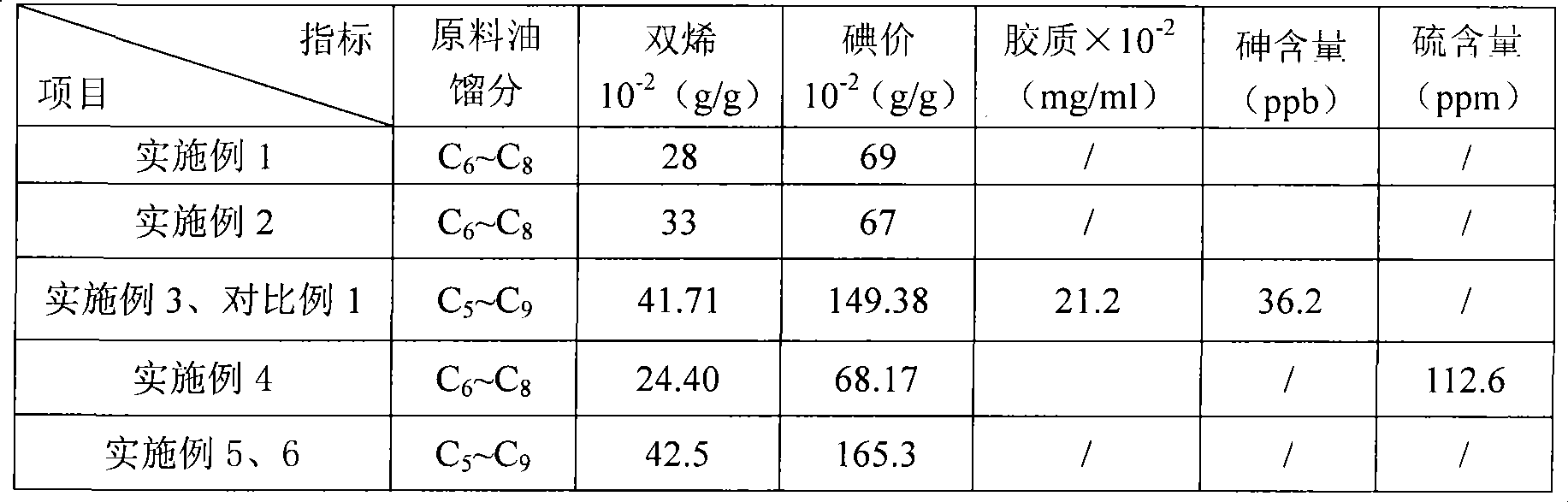

Embodiment 1

[0036] Put the fresh catalyst 1 into a 100ml adiabatic bed reaction device, reduce it for 7 hours under the conditions of pressure 0.03MPa, temperature 120°C, and volume ratio of hydrogen to catalyst 200:1, then feed the raw material oil after cooling down to 40°C; the reaction process conditions are: The inlet temperature is 40°C, the volume ratio of hydrogen to oil is 350:1, the reaction pressure is 2.8MPa, and the fresh oil space velocity is 3.0h -1 ; The average diene of the hydrogenation product within 170 hours of operation is 0.77 gram of iodine / 100 gram of oil, and the iodine value is 26.1 gram of iodine / 100 gram of oil.

Embodiment 2

[0038] Put the fresh catalyst 2 into a 100ml adiabatic bed reaction device, reduce it for 9 hours under the conditions of pressure 0.03MPa, temperature 100°C, and volume ratio of hydrogen to catalyst 500:1, then feed the raw material oil after cooling down to 40°C; the reaction process conditions are: The inlet temperature is 45°C, the volume ratio of hydrogen to oil is 200:1, the reaction pressure is 2.5MPa, and the space velocity of fresh oil is 3.5h -1 ; The average diene of the hydrogenation product within 168 hours of operation is 0.42 gram of iodine / 100 gram of oil, and the iodine value is 27.65 gram of iodine / 100 gram of oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com