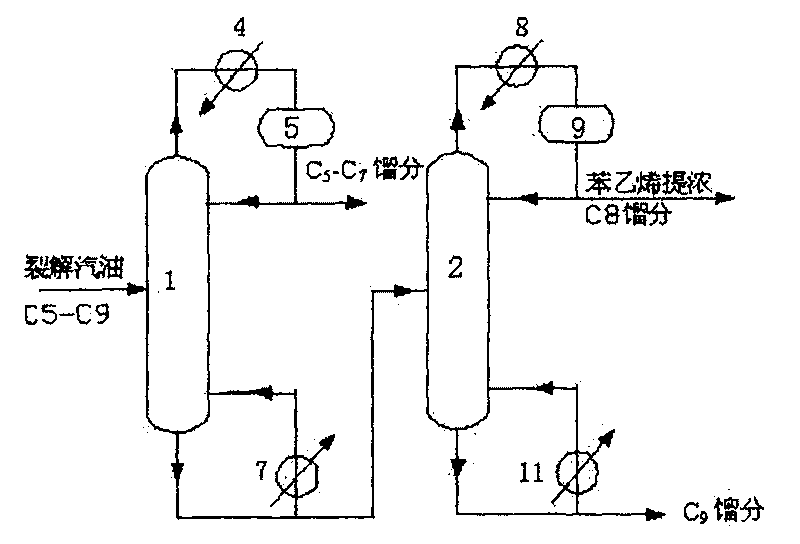

Device and method for separating rough styrene contained in pyrolysis gasoline

A crude styrene and pyrolysis gasoline technology, applied in distillation purification/separation, petroleum industry, hydrocarbon distillation, etc., can solve the problems of ineffective separation of fractions, high energy consumption, long separation process, etc., and achieve the effect of saving auxiliary equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

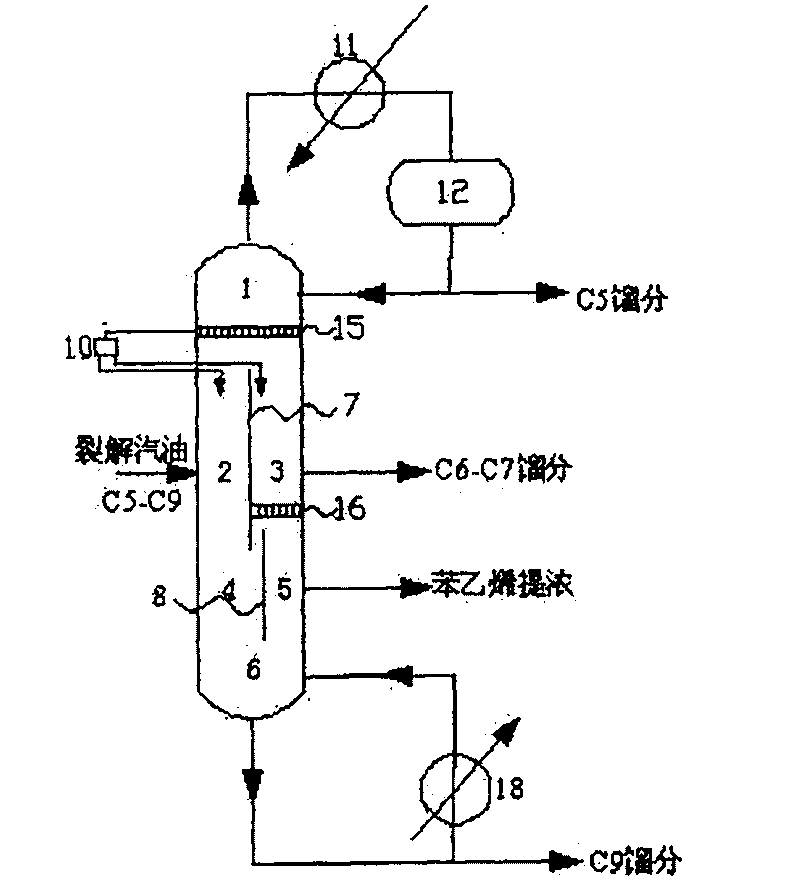

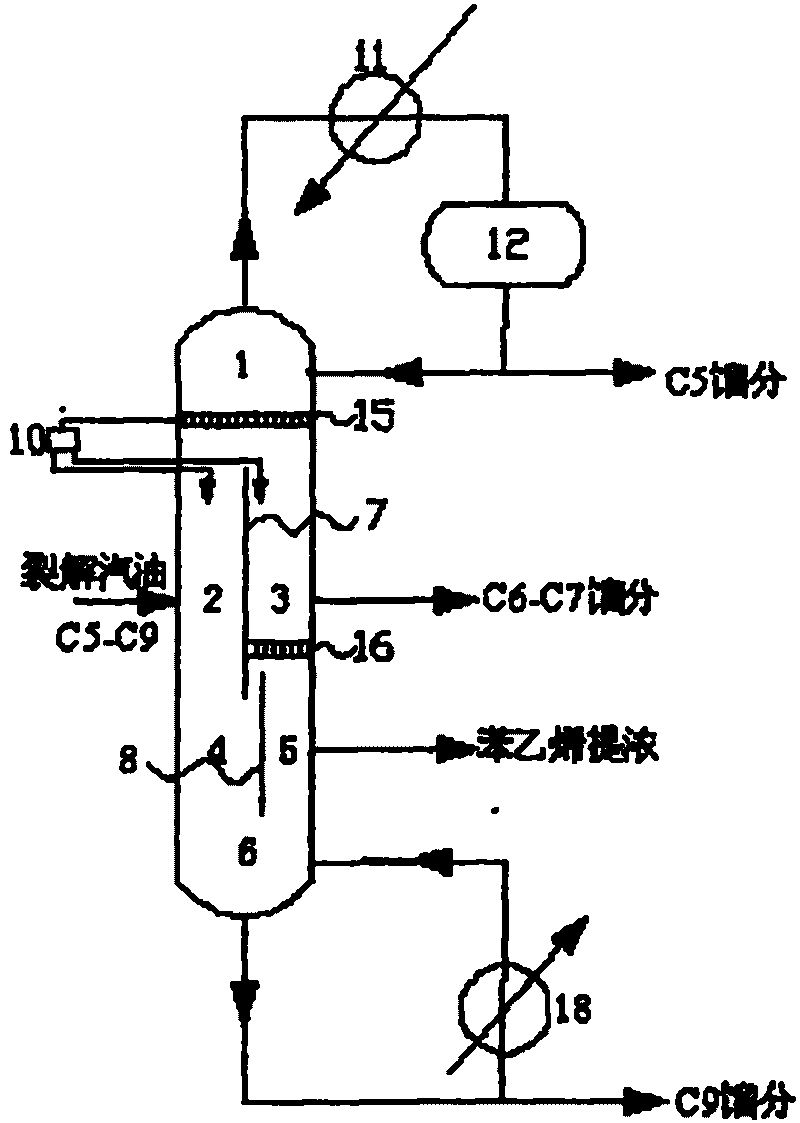

Method used

Image

Examples

Embodiment 1

[0022] Feed with the raw materials in Table 1, the height of the dividing wall rectification tower H=8300mm, the diameter of 76mm, the height of the dividing wall 7 is 2500mm, the height of the dividing wall 8 is 1500mm, the total number of theoretical plates is 100-110, the pressure at the top of the tower is 1atm, and the feed Feed at the center of zone 2, the feed rate is 10kg / h, the reflux ratio is 2, the liquid distribution ratio (C 6 -C 7 Discharge area 3: feed area 2) is 2:1, tower top discharge 1.5kg / h, C 6 -C 7 Discharge at the center of discharge area 3, side line C 6 -C 7 The production rate is 4.7kg / h, the crude styrene is discharged from the center of the discharge area 5, and the side line C 8 The production rate is 2.5kg / h, the tower top temperature is 15-20℃, C 6 -C 7 The discharge temperature is 80-85°C, the crude styrene discharge temperature is 110-120°C, and the tower kettle temperature is 150-160°C. Under this condition, the tower top C 5 The mass ...

Embodiment 2

[0026] Feed with the raw material of Table 1, in the same dividing wall rectifying tower as embodiment 1, under the same situation of operating conditions, only change the discharge position, side line C 6 -C 7 Outlet position ratio C 6 -C 7 The central position of the discharge area 3 is 5 theoretical plates lower, and the crude styrene discharge position is 3 theoretical plates lower than the central position of the crude styrene discharge area 5. Under this condition, the tower top C 5 The mass percentage content reaches 99.90%; side line C 6 -C 7 In discharge C 5 The massfraction of styrene is 0.85%; the yield of styrene can reach 99.20%, and the tower still C 8 The mass fraction is 0.30%

Embodiment 3

[0028] Table 2 The mass fraction of each component of pyrolysis gasoline

[0029]

[0030] Feed with the raw material of Table 2, in the same dividing wall rectifying tower as embodiment 1, the inlet and outlet position is the same as embodiment 1, tower top pressure 0.5atm, feed rate is 10kg / h, and reflux ratio is 2, and liquid The distribution ratio (C6-C7 discharge area 3: feed area 2) is 1:2, the output at the top of the tower is 1.0kg / h, the recovery rate of side line C6-C7 is 4.7kg / h, and the recovery rate of side line C8 is 3.0 kg / h, the discharge temperature of C6-C7 is 60-75°C, the discharge temperature of crude styrene is 90-100°C, and the temperature of the tower kettle is 130-140°C. Under these conditions, the mass percentage of C5 at the top of the tower reaches more than 99.95%; the mass fraction of C5 in the side line C6-C7 discharge is 0.46%; the yield of styrene can reach 99.50%, and the mass fraction of C8 in the tower kettle is 0.50%. %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com