Preparation method for hollow silver sulfide microspheres

A technology of silver sulfide and microspheres, which is applied in the fields of copper sulfide, textiles, papermaking, fiber treatment, etc. It can solve the problems of difficult mass production, complex process, high toxicity, etc., and achieve low cost, good water solubility, and uniform particle size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

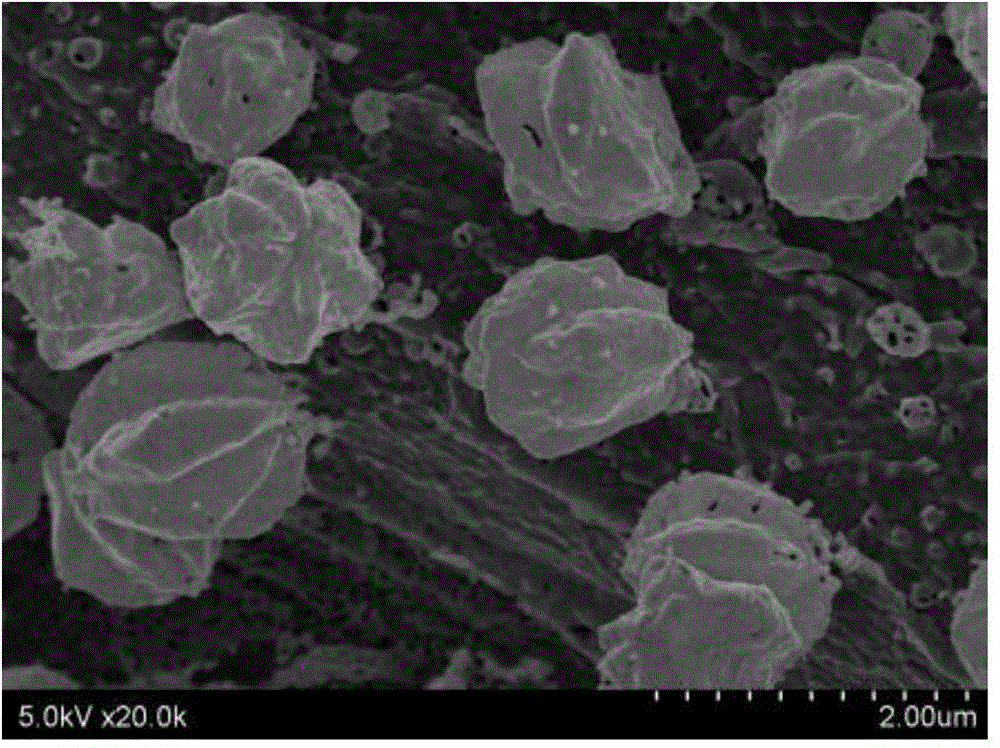

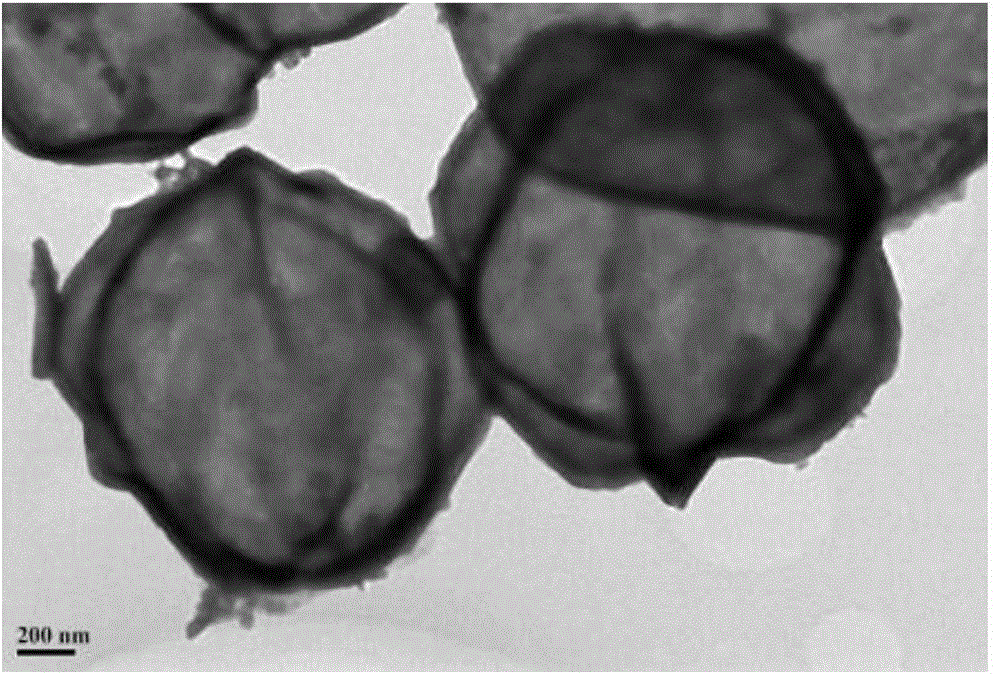

[0026] Mix 50mL 0.04mol / L thiourea aqueous solution with 25mL 0.04mol / L silver nitrate aqueous solution, then add 25mL 0.04mol / L sodium chloride aqueous solution, after adding the reaction solution, place it at 4°C for 2 hours, and filter the resulting precipitate Then add water to wash and dry; add the precipitate to 100mL of 50mL / L diethanolamine aqueous solution, react at 80°C for 15min under the aid of microwave, naturally cool, filter and dry to obtain the product. The SEM and TEM images of the product are attached figure 1 and 2 .

Embodiment 2

[0028] Mix 50mL 0.02mol / L thiourea aqueous solution with 25mL 0.02mol / L silver nitrate aqueous solution, then add 25mL 0.02mol / L sodium chloride aqueous solution, after adding the reaction solution, place it at 4°C for 2 hours, and filter the resulting precipitate Then add water to wash and dry; add the precipitate to 100mL of 25mL / L diethanolamine aqueous solution, react at 70°C for 25min under the aid of microwave, naturally cool, filter and dry to obtain the product.

Embodiment 3

[0030] Mix 50mL of 0.04mol / L thiourea aqueous solution with 25mL of 0.04mol / L silver fluoride aqueous solution, then add 25mL of 0.04mol / L potassium chloride aqueous solution. After filtration, add water to wash and dry; add the precipitate to 100mL of 50mL / L diethanolamine aqueous solution, react at 80°C for 15min under the aid of microwave, naturally cool, filter and dry to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com