Strengthened polysulfone nano-fiber air filter membrane and electrostatic spinning preparation method thereof

A nanofiber and air filtration technology, applied in separation methods, chemical instruments and methods, membrane technology, etc., can solve the problem of difficult to achieve controllable preparation of reinforced polysulfone nanofiber air filtration membranes, poor adhesion of substrates, and fiber structure. Changes and other problems, to achieve the effect of enhancing automatic cleaning performance, prolonging service life, and improving structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

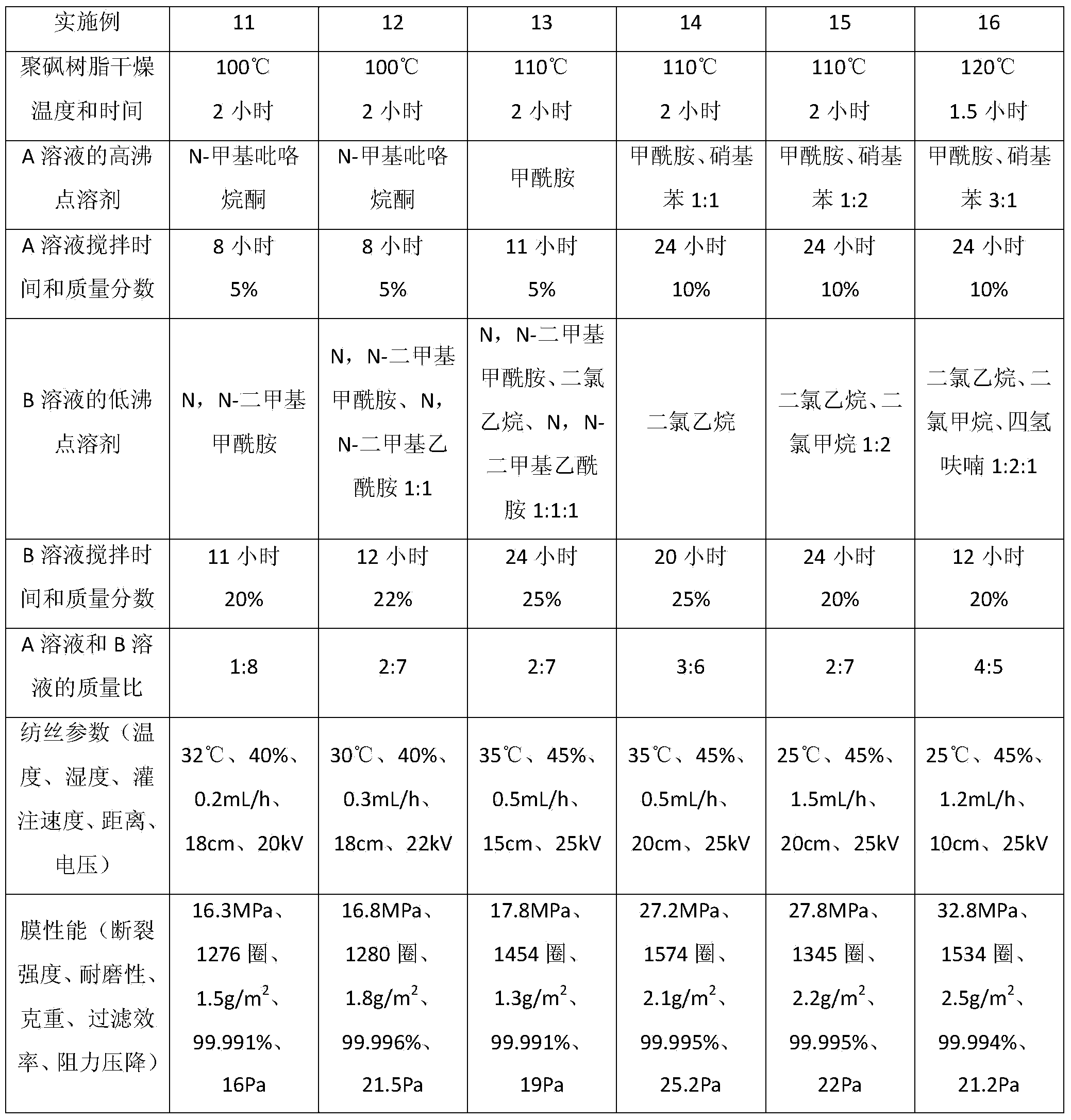

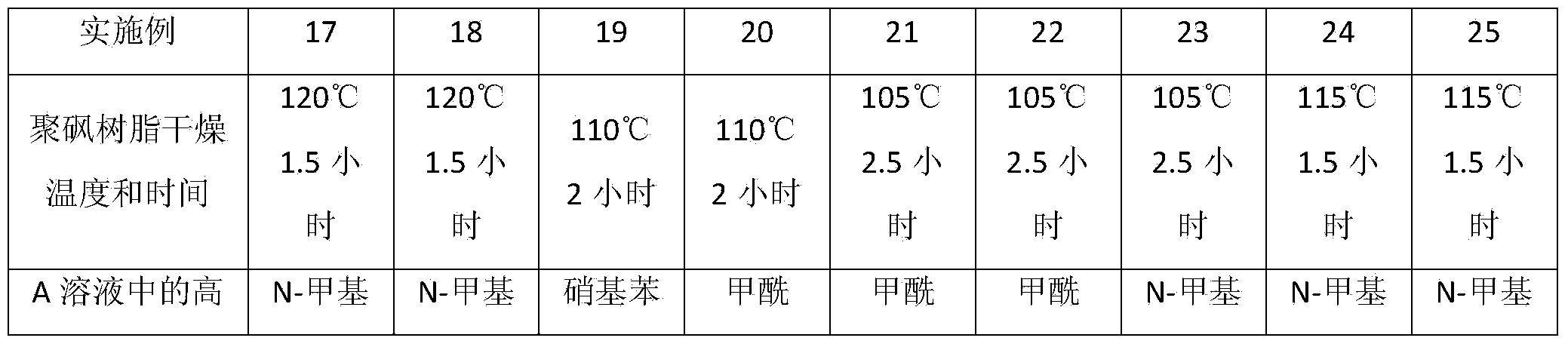

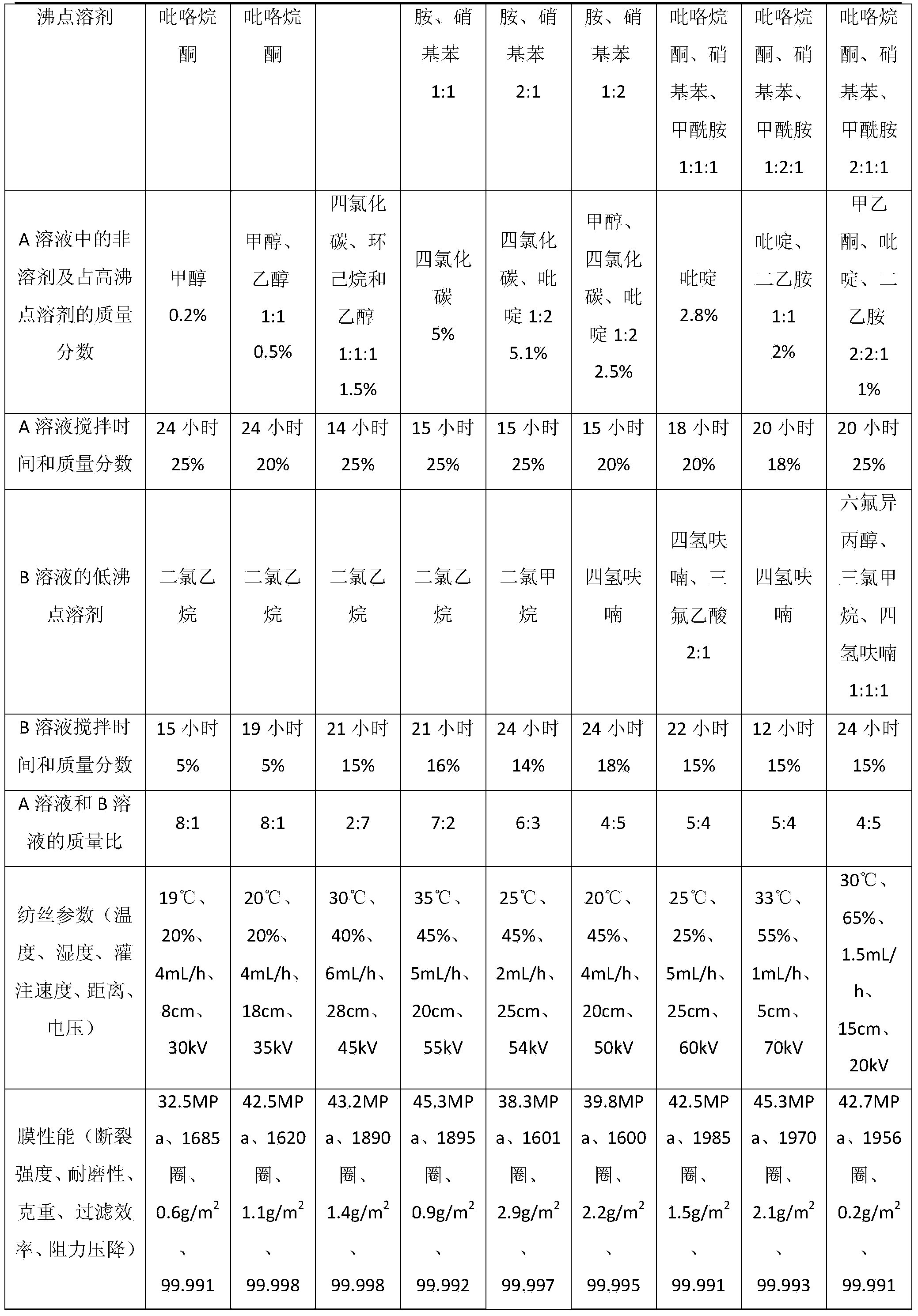

Examples

Embodiment 1

[0026] A reinforced polysulfone nanofiber air filter membrane and its electrospinning preparation method, the specific steps are:

[0027] Step 1: Place the polysulfone resin particles in a vacuum oven and dry them under vacuum at 100°C for 3 hours;

[0028] The second step: dissolve the dried polysulfone resin particles in a 1:1:1 mixed solvent of N-methylpyrrolidone, dimethyl sulfoxide and formamide, and place on a magnetic stirrer to stir for 8 hours to form Homogeneous solution; In the homogeneous solution, the massfraction of polysulfone resin is 5%;

[0029] Step 3: Dissolve the dried polysulfone resin particles in a 1:1 mixed solvent of N,N-dimethylacetamide and N,N-dimethylformamide, and stir on a magnetic stirrer 12 hours, form homogeneous solution; In described homogeneous solution, the massfraction of polysulfone resin is 20%;

[0030] The fourth step: under the conditions of temperature 35°C and humidity 50%, the polysulfone electrospinning solution with a mass f...

Embodiment 2

[0032] A reinforced polysulfone nanofiber air filter membrane and its electrospinning preparation method, the specific steps are:

[0033] Step 1: Place the polysulfone resin particles in a vacuum oven and dry them under vacuum at 120°C for 1.5 hours;

[0034] The second step: dissolve the dried polysulfone resin particles in a 1:1 mixed solvent of nitrobenzene and N-methylpyrrolidone, and then add 1 dropwise of methanol, ethanol and isobutanol to the solution : 1:1 mixed solution, the solution was placed on a magnetic stirrer and stirred for 24 hours to form a homogeneous solution; in the homogeneous solution, the total mass of methanol, ethanol and isobutanol was nitrobenzene and N-formazol 0.1% of the total mass of pyrrolidone, and the mass fraction of polysulfone resin is 25%;

[0035] The third step: dissolve the dried polysulfone resin particles in a 2:1:1 mixed solvent of dichloroethane, chloroform and tetrahydrofuran, and place on a magnetic stirrer to stir for 16 hou...

Embodiment 3

[0038] A reinforced polysulfone nanofiber air filter membrane and its electrospinning preparation method, the specific steps are:

[0039] Step 1: Place the polysulfone resin particles in a vacuum oven and dry them under vacuum at 110°C for 2.5 hours;

[0040] Second step: dissolve the dried polysulfone resin particles in a 1:1 mixed solvent of 2-phenoxyethanol and ethyl benzoate, place the solution on a magnetic stirrer and stir for 20 hours to form a uniform phase solution; in the homogeneous solution, the massfraction of polysulfone resin is 35%;

[0041] The third step: dissolve the dried polysulfone resin particles in a 1:1 mixed solvent of trifluoroacetic acid and hexafluoroisopropanol, and then add toluene, xylene, phenol, chlorinated 1:1:1:1:1 mixed solvent of benzene and water, and described solution is placed on magnetic stirrer and stirred for 24 hours, forms homogeneous solution; In described homogeneous solution, toluene, xylene, phenol, The total mass of chloro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com