Method for preparing copper hydroxide and copper oxide nano material and application

A copper hydroxide and nanomaterial technology, applied in copper oxide/copper hydroxide, nanostructure manufacturing, nanotechnology and other directions, can solve the problems of affecting health, pollute the environment, and high cost, and achieve significant production practical significance and preparation cost. Low, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

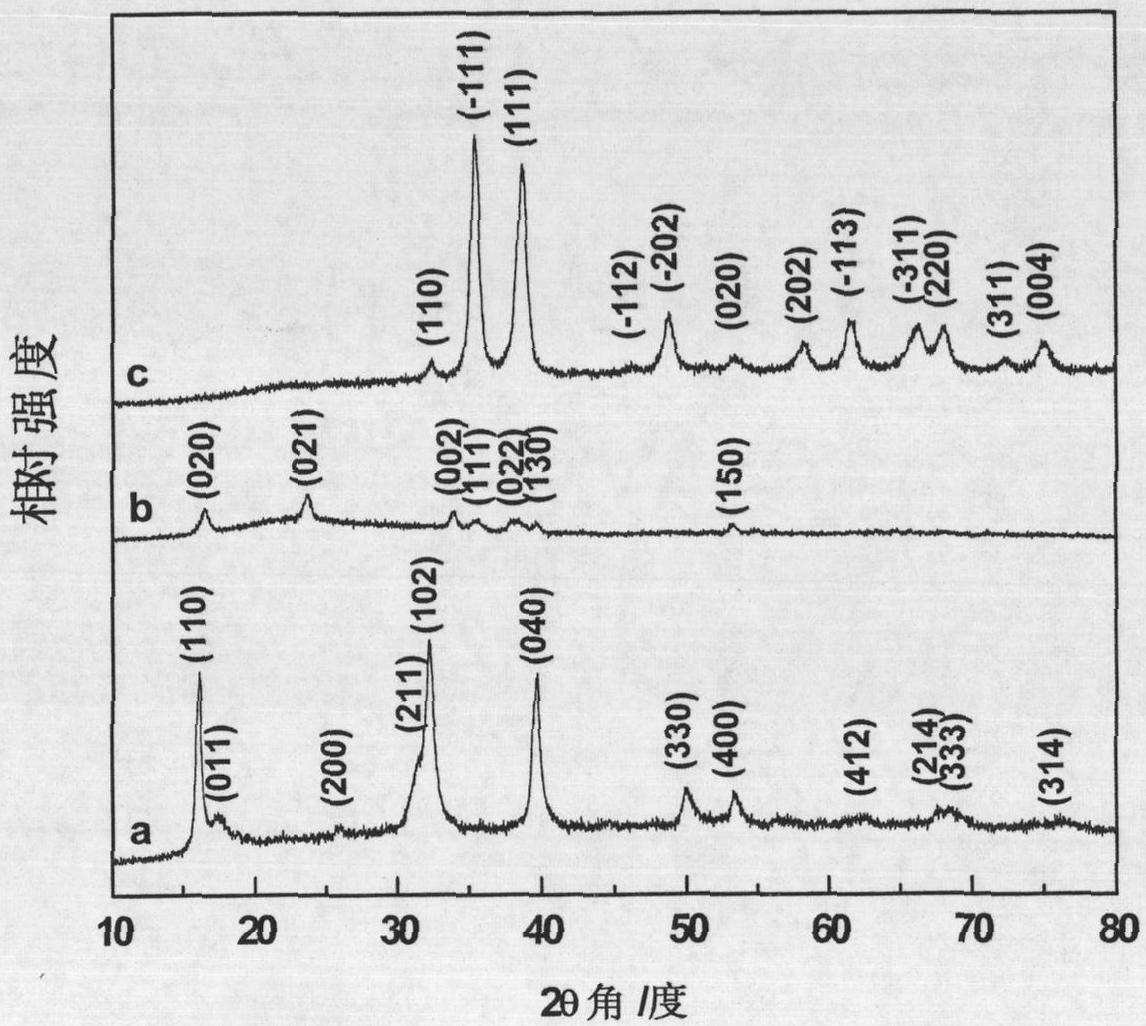

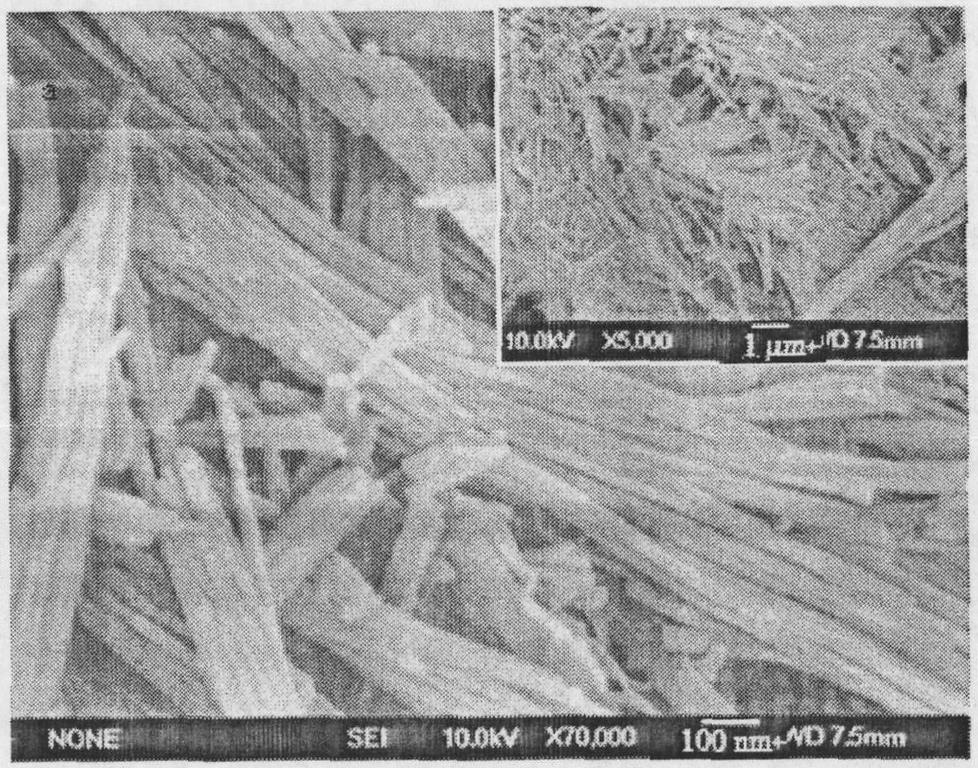

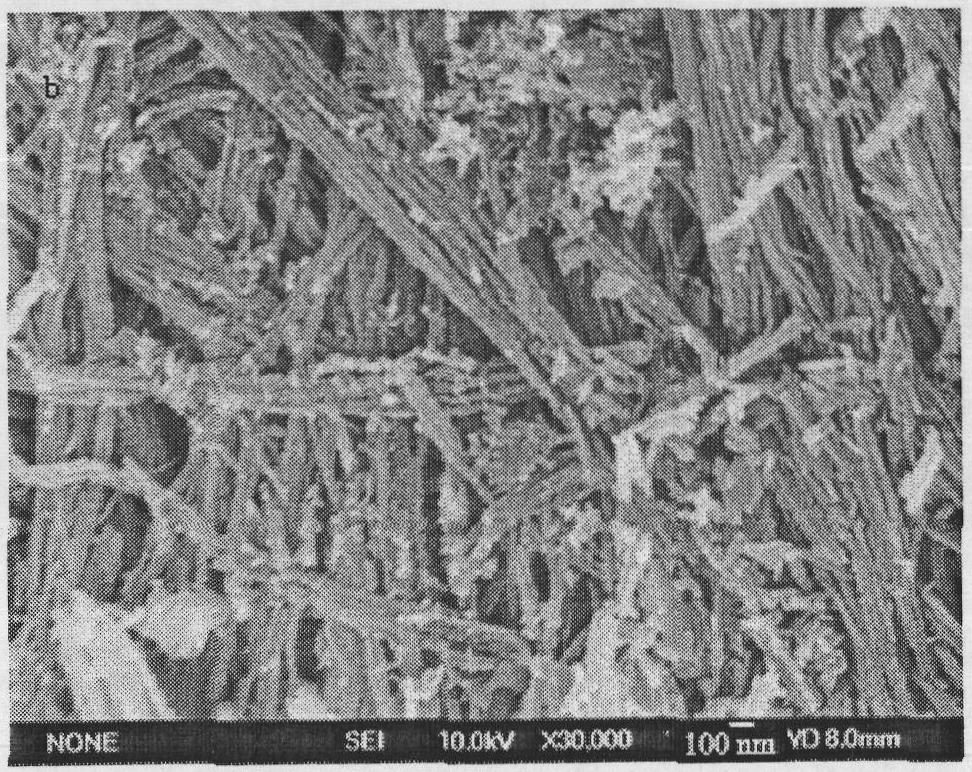

[0028] The present invention provides a kind of preparation method of copper hydroxide and copper oxide nano material, and it uses green salt copper ore Cu 7 Cl 4 (OH) 10 ·H 2 O is the precursor, and copper hydroxide Cu(OH) can be rapidly prepared by ultrasonic-assisted method under the condition of no template agent. 2 Nanomaterials such as nanowires, CuO nanowires with secondary structures, and CuO nanosheets, specifically include the following steps:

[0029] The first step, the preparation of green copper ore Cu as a precursor 7 Cl 4 (OH) 10 ·H 2 O;

[0030] This step is specifically: under strong stirring, slowly add sodium hydroxide NaOH aqueous solution to copper chloride CuCl at a temperature of 50-70°C. 2 In aqueous solution, the hydroxide ion OH - with copper ions Cu 2+The molar ratio between them is 0.5:1, and then the obtained suspension is separated with a centrifuge to obtain a green precipitate, and then the green precipitate is washed with deionized w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com