Copper oxide micro-nano composite structural material and preparation method thereof

A composite structure, micro-nano technology, applied in copper oxide/copper hydroxide, nanotechnology and other directions, can solve problems such as being unsuitable for large-scale application, complex synthesis process, expensive reaction equipment, etc., and is conducive to large-scale popularization and application, The effect of low preparation cost and significant production practical significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

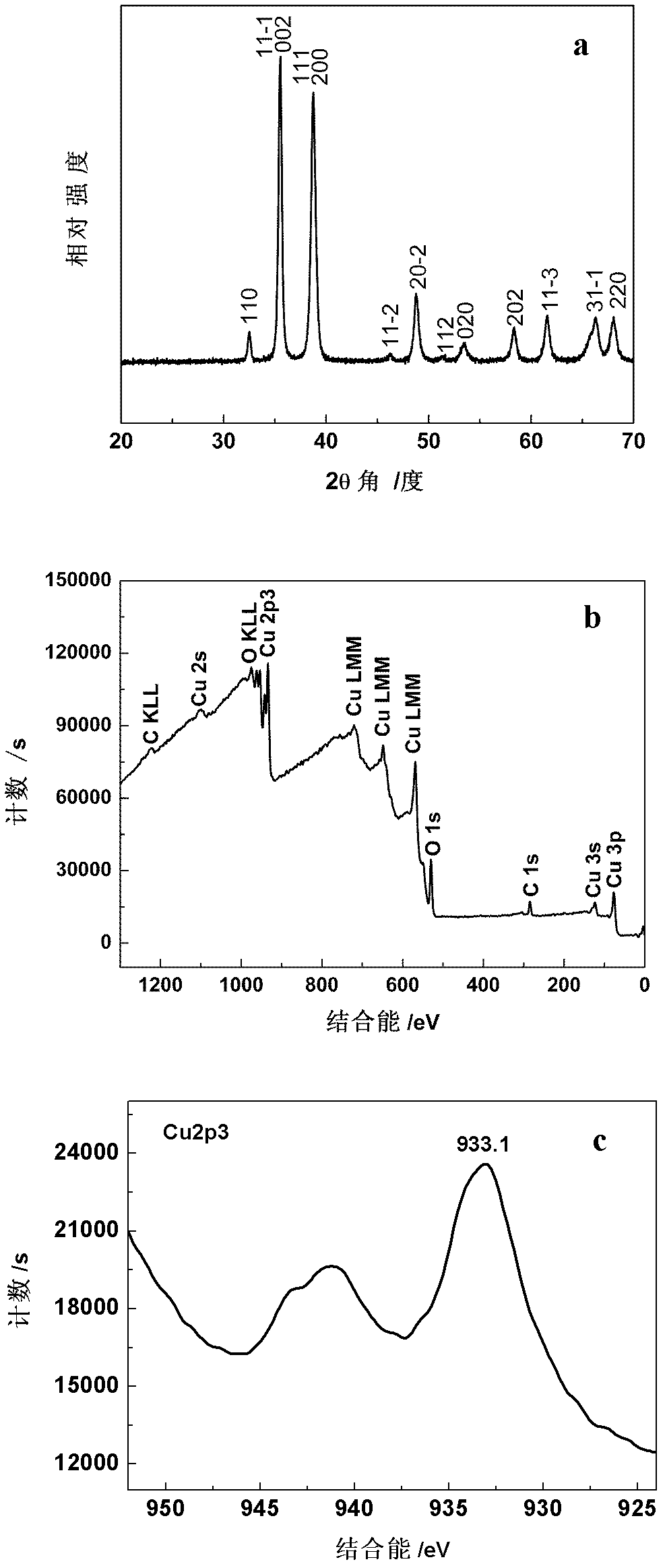

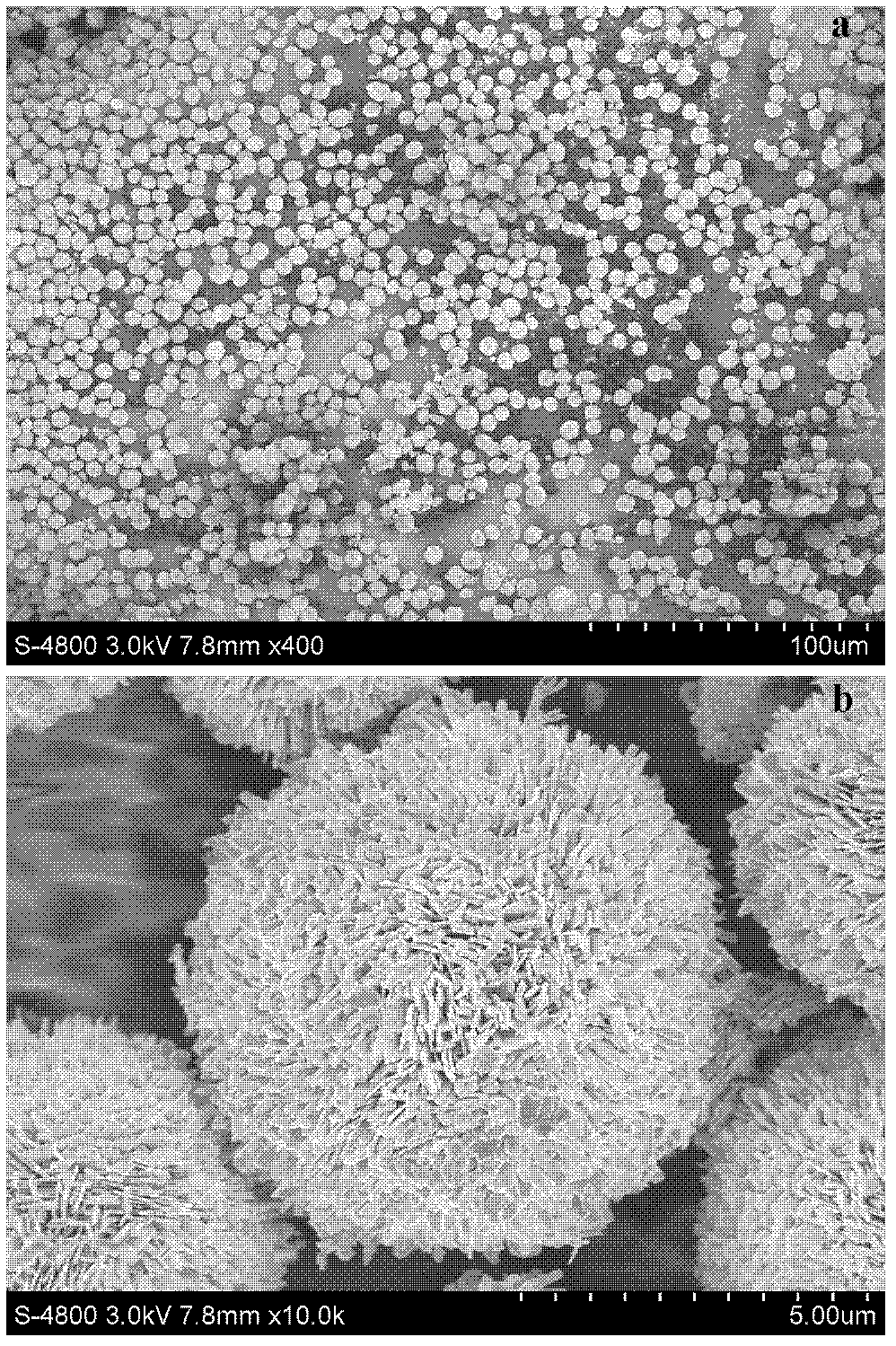

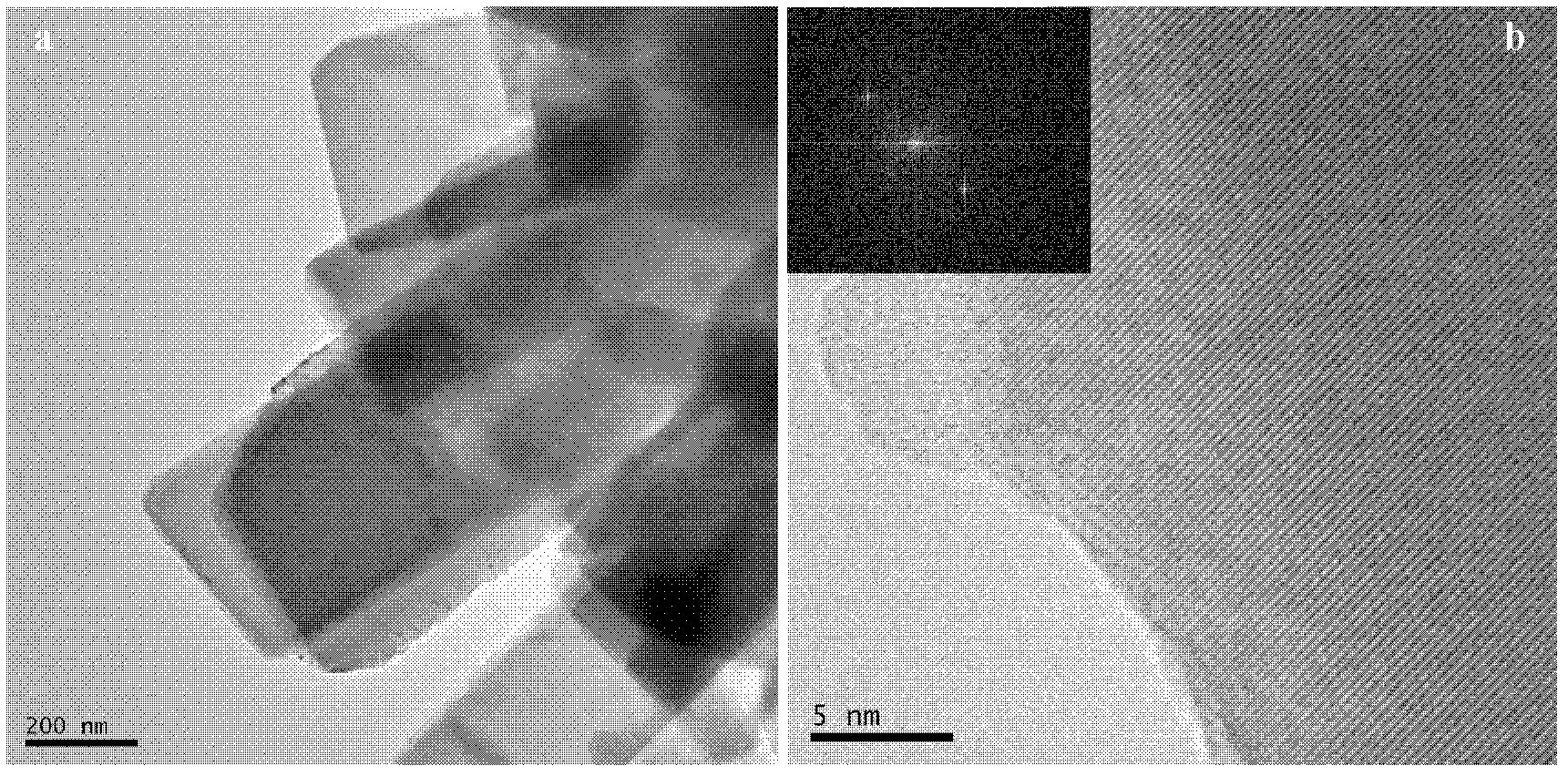

[0026] A method for preparing a copper oxide microsphere material with a nanosheet secondary structure, comprising the following steps:

[0027] 1) 0.6g copper chloride (CuCl 2 2H 2 O) be dissolved in 5mL deionized water under stirring, then under magnetic stirring, 15mL of mass percentage concentration is 25% ammoniacal liquor, 1.5g solid sodium hydroxide and 0.61g sodium dodecylbenzenesulfonate are added successively to the above-mentioned solution, and then continue to stir for 15 minutes to generate blue tetraammine copper [Cu(NH 3 ) 4 ] 2+ Complex cations and copper tetrahydroxide [Cu(OH) 4 ] 2- With anion mixture;

[0028] 2) Transfer the above mixed solution into a stainless steel reaction kettle with polytetrafluoroethylene lining. The volume of the reaction kettle is 25mL. After sealing, place the reaction kettle in a constant temperature drying oven at 180°C and heat for 8 hours to obtain a black product;

[0029] 3) Naturally cool the reactor to room temperat...

Embodiment 2

[0034] A preparation method of copper oxide nano sheet material, comprising the following steps:

[0035] 1) 0.6g copper chloride (CuCl 2 2H 2 O) Dissolve in 5mL deionized water under stirring, then add 1.5g solid sodium hydroxide and 0.61g sodium dodecylbenzenesulfonate to the above solution successively under magnetic stirring, then continue stirring for 15 minutes to form blue Copper hydroxide Cu(OH) 2 suspension;

[0036] 2) Transfer the above suspension into a stainless steel reaction kettle with polytetrafluoroethylene lining. The volume of the reaction kettle is 25mL. After sealing, place the reaction kettle in a constant temperature drying oven at 180°C and heat for 8 hours to obtain a black product;

[0037] 3) Naturally cool the reactor to room temperature, then centrifuge the resulting black product, and wash the resulting solid three times with deionized water and absolute ethanol to remove residual soluble ions and surfactant SDBS in the precipitate, deionized ...

Embodiment 3

[0041] A preparation method of a fan / rod-shaped copper oxide material, comprising the following steps:

[0042] 1) 0.6g copper chloride (CuCl 2 2H 2 0) be dissolved in 5mL deionized water under stirring, then under magnetic stirring, 15mL mass percent concentration is 25% ammoniacal liquor and 0.61g sodium dodecylbenzenesulfonate are added in the above-mentioned solution successively, then continue to stir for 15 Minutes, blue tetraammine copper [Cu(NH 3 ) 4 ] 2+ With cationic solution;

[0043] 2) The above-mentioned blue tetraammine copper [Cu(NH 3 ) 4 ] 2+ The cationic solution was transferred into a stainless steel reaction kettle with a polytetrafluoroethylene lining. The volume of the reaction kettle was 25mL. After sealing, the reaction kettle was placed in a constant temperature drying oven at 180°C and heated for 8 hours to obtain a black product;

[0044] 3) Naturally cool the reactor to room temperature, then centrifuge the resulting black product, and wash ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com