Preparation method of shape-controlled micro-nano ZnO under normal pressure and low temperature conditions

A low-temperature, micro-nano technology, applied in zinc oxide/zinc hydroxide and other directions, can solve the problems of poor size control effect, poor morphology uniformity, low crystallinity, etc., and achieve low raw material prices, easy raw materials, and safety. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

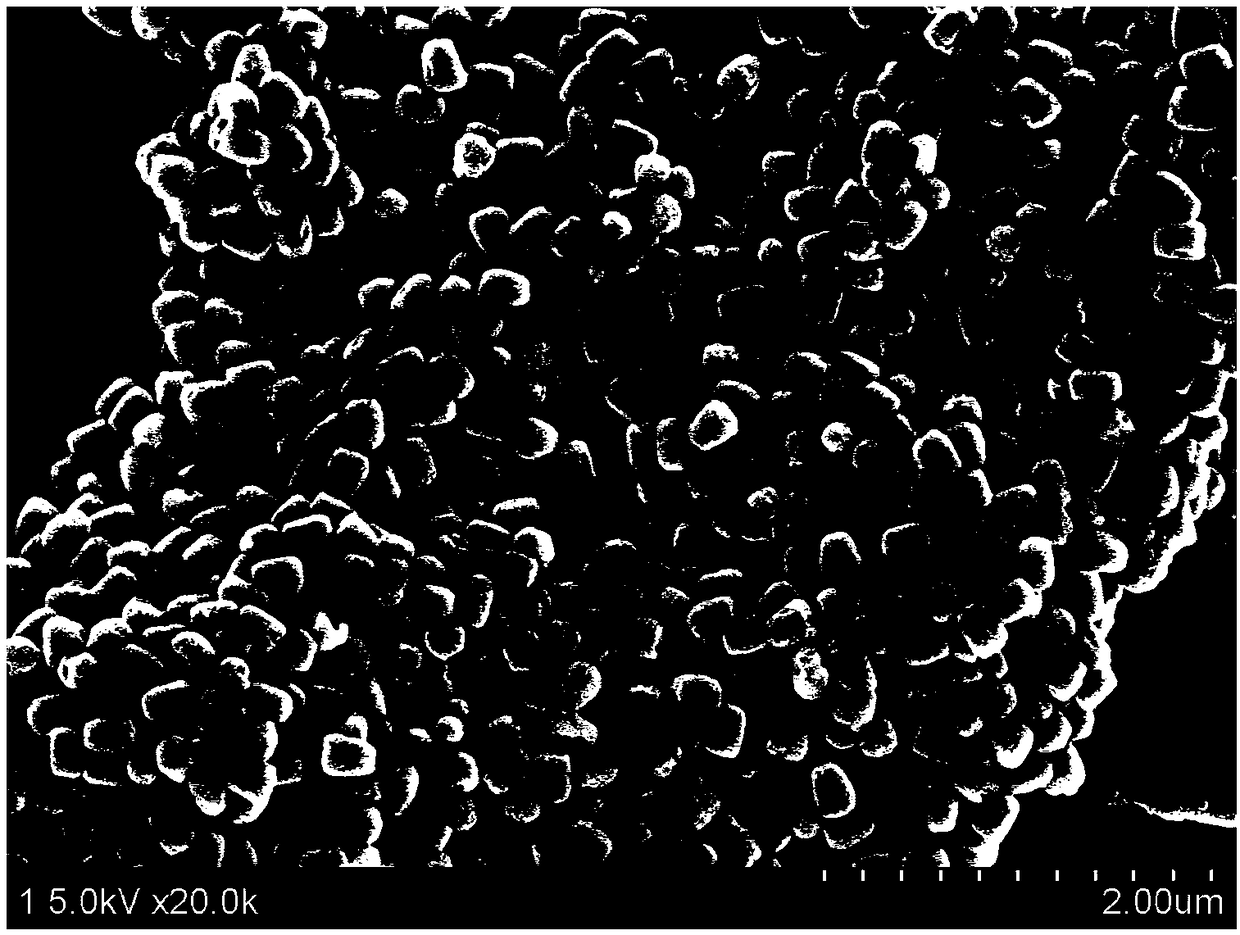

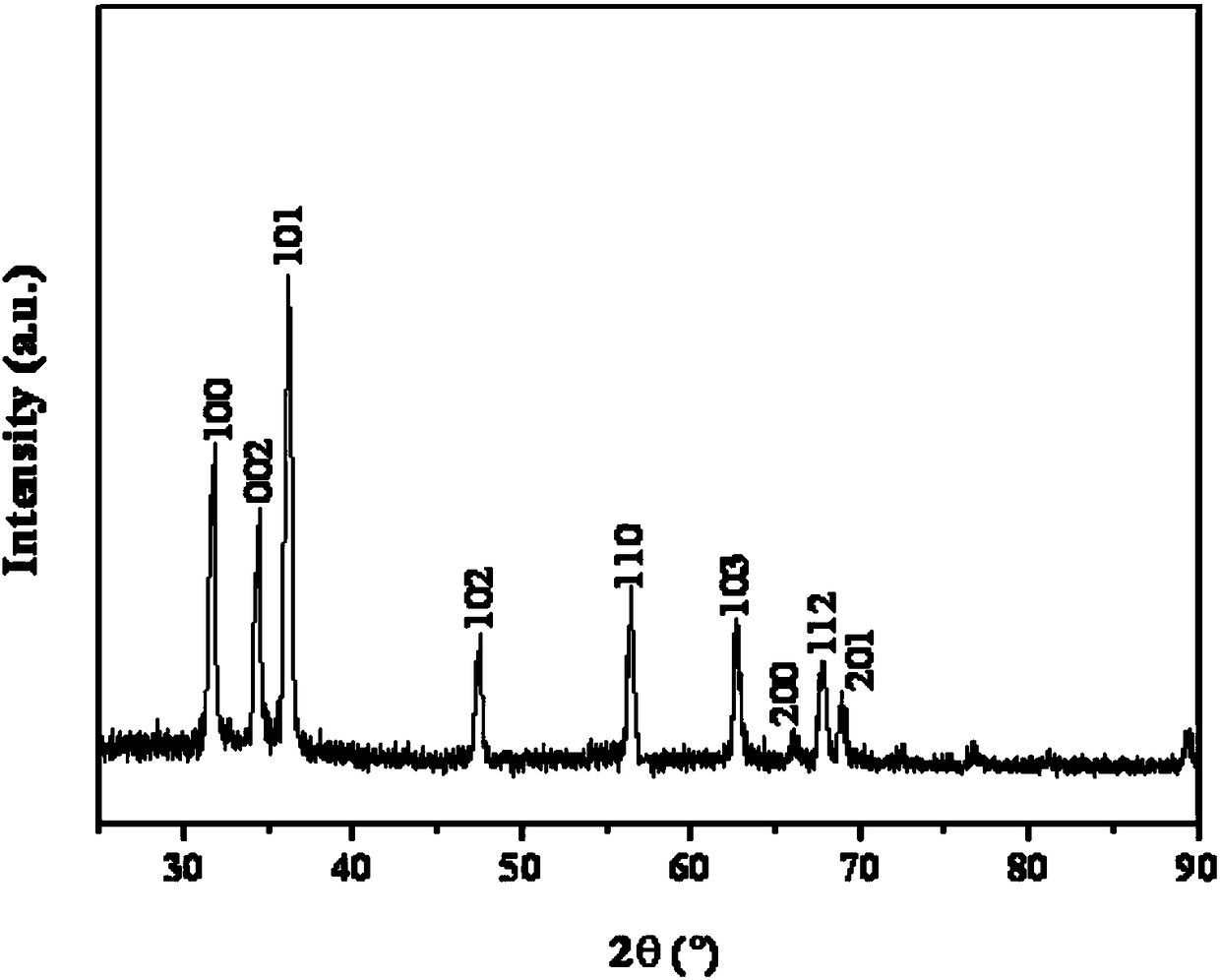

[0024] Add 2mmol of zinc acetate to a mixed solution of 60mL of dimethylformamide and water (volume ratio: 2:1), then add 6mmol of oleylamine, heat and react at 85°C for 30min in an open system at normal pressure, cool, centrifuge, and wash , freeze-dried to obtain micronano ZnO. The SEM image and XRD image of the product are shown in figure 1 and 2 . From the SEM image of the product ( figure 1 ) shows that the morphology of the product is a hexagonal semi-pyramid columnar body, the length is about 260nm, and the diameter of the thickest end is about 200nm. The XRD figure of product ( figure 2 ) results are consistent with the standard XRD spectrum (JCPDS No.36-1451), which proves that the crystal phase of the obtained product is a hexagonal ZnO phase with high crystallinity.

Embodiment 2

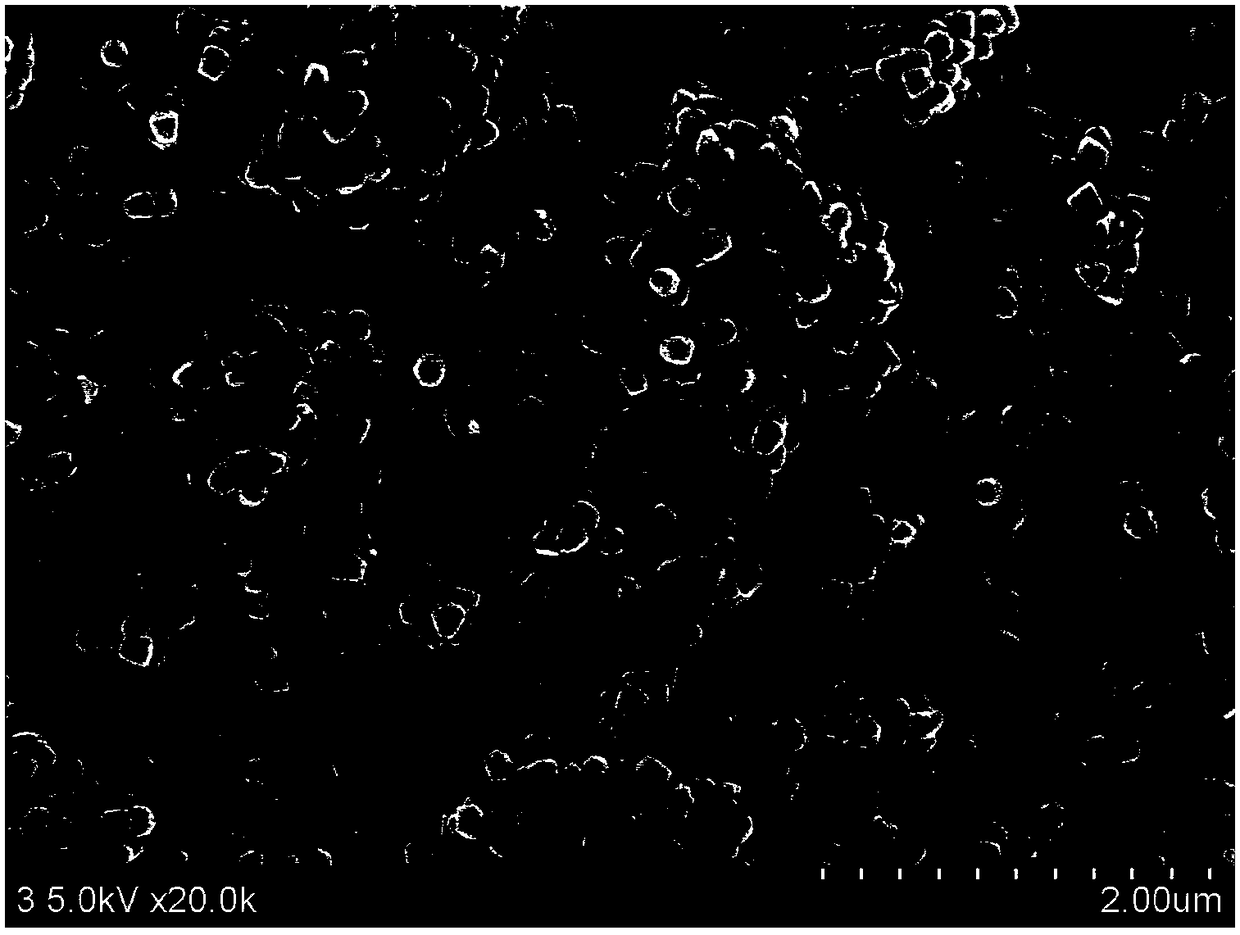

[0026] Add 1mmol of zinc nitrate to a mixed solution of 40mL of dimethylformamide and water (volume ratio 1:1), then add 2mmol of oleylamine, heat and react at 80°C for 60min in an open system at normal pressure, cool, centrifuge, and wash , freeze-dried to obtain micronano ZnO. The SEM image of the product is shown in image 3 . It can be seen from the SEM image that the morphology of the product is a hexagonal semi-pyramid columnar body, the length is about 160nm, and the diameter of the thickest end is about 150nm.

Embodiment 3

[0028] Add 1mmol of zinc acetate to a mixed solution of 60mL of dimethylformamide and water (volume ratio: 3:1), then add 4mmol of oleylamine, heat and react at 90°C for 20min in an open system at normal pressure, cool, centrifuge, and wash , freeze-dried to obtain micronano ZnO. The SEM image of the product is shown in Figure 4 . It can be seen from the SEM image that the product is in the shape of a brush-shaped column with a long handle, the total length is about 1-2 μm, the length of the handle is about 480 nm, and the diameter of the brush end is about 650 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com