Needle-like copper hydroxide material based on copper grid, preparation method and oil-water separating method

A technology of copper hydroxide and sodium hydroxide, applied in the direction of copper oxide/copper hydroxide, immiscible liquid separation, metal material coating process, etc., can solve the problems of expensive, large-scale equipment, power consumption, etc., and achieve easy operation , avoid environmental pollution, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

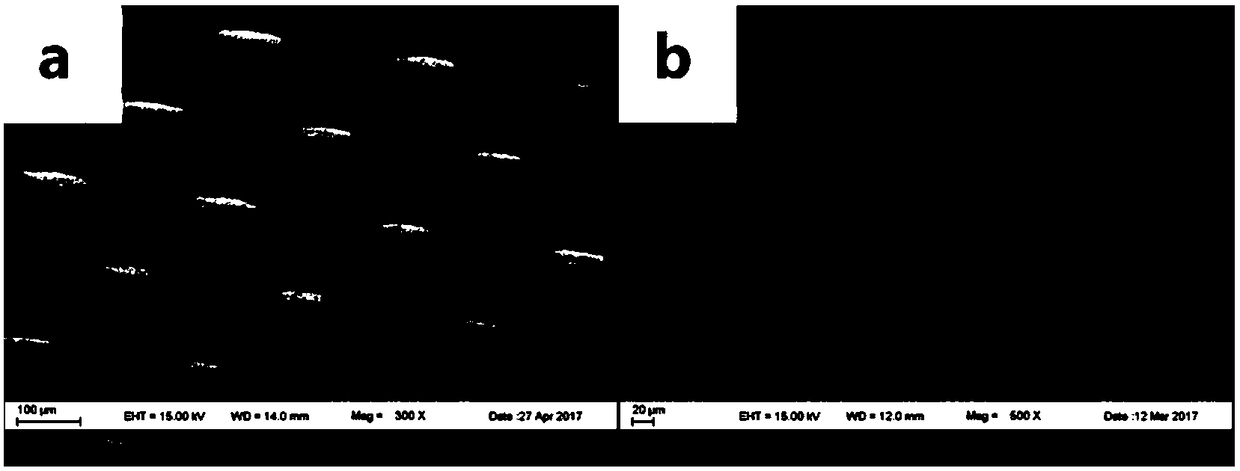

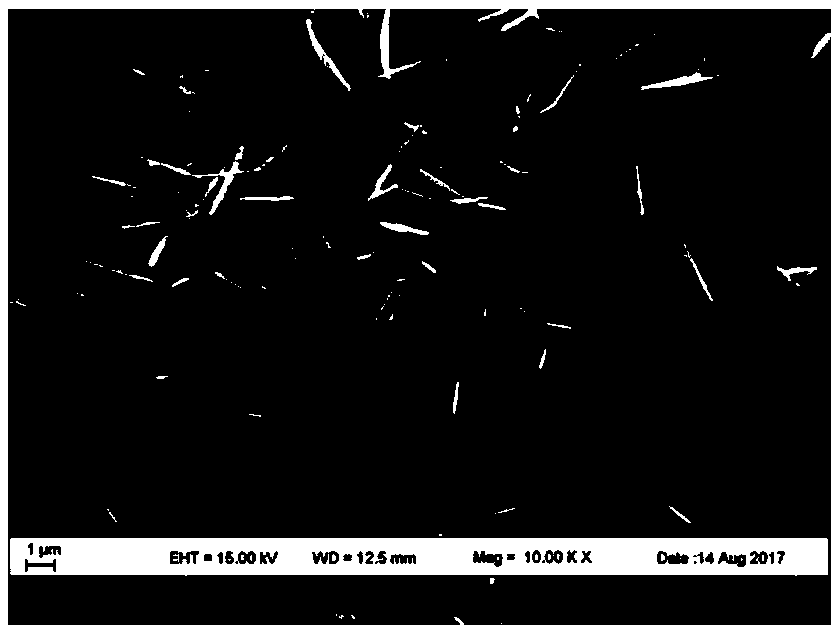

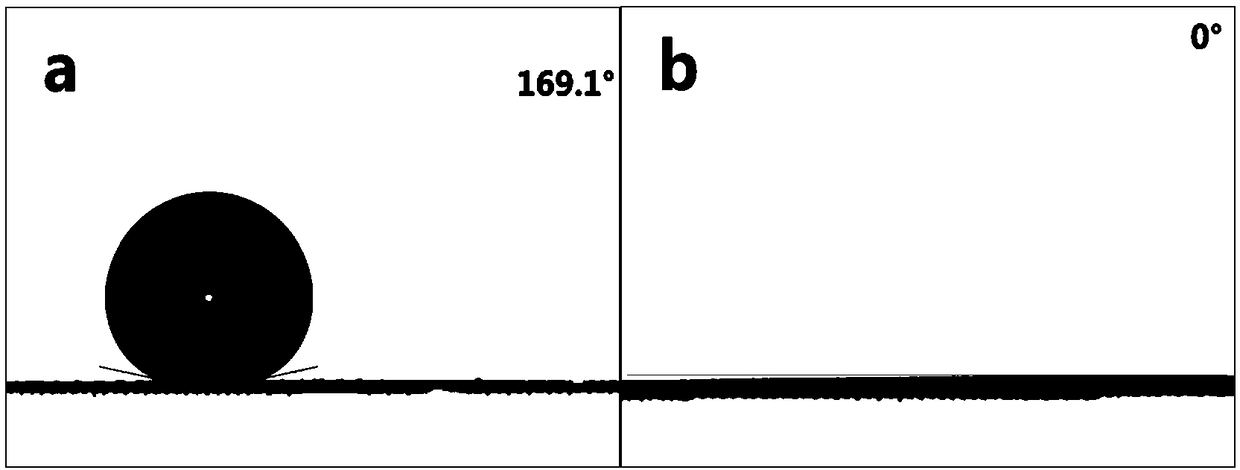

[0043] Prepare superhydrophobic acicular copper hydroxide on the surface of copper mesh, the specific steps are as follows:

[0044] (1) Polish the copper mesh (the mesh number of the copper mesh is 100 mesh, the copper mesh material is pure copper, the purity is 98%) with sandpaper to remove part of the oxide layer on the surface, ultrasonic cleaning in absolute ethanol and deionized water for 5 minutes respectively, nitrogen gas Blow dry and set aside.

[0045] (2) Put the copper mesh treated in step (1) into the mixed solution 1 of sodium hydroxide and ammonium persulfate at 24°C (the concentration of sodium hydroxide solution is 2.5mol L -1 , the concentration of ammonium persulfate solution is 0.05mol L -1 ) for 45 minutes; then put it into the mixed solution 1 diluted 10 times to react for 60 minutes; then put it into deionized water and react for 60 minutes.

[0046] (3) Rinse the sample obtained in step (2) with deionized water, blow dry with nitrogen, and obtain nee...

Embodiment 2

[0052] Prepare superhydrophobic acicular copper hydroxide on the surface of copper mesh, the specific steps are as follows:

[0053] (1) Wipe off part of the oxide layer on the surface of the copper mesh (the mesh number of the copper mesh is 200 mesh) with sandpaper, then ultrasonically clean it in absolute ethanol and deionized water for 10 minutes, and blow dry with nitrogen.

[0054] (2) Put the copper mesh treated in step (1) into the mixed solution 1 of sodium hydroxide and ammonium persulfate at a temperature of 27°C (the concentration of the sodium chloride solution is 2.5mol L -1 and ammonium persulfate solution concentration is 0.05mol L -1 ) for 30 minutes; then put it into the mixed solution 1 diluted 10 times for 60 minutes; then put it into deionized water for 60 minutes.

[0055] (3) Rinse the sample obtained in step (2) with deionized water, dry it naturally, and obtain needle-shaped copper hydroxide on the surface of the copper mesh.

[0056] (4) Dip the cop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com