Biomass fiber-based three-dimensional porous material and preparation method thereof

A biomass fiber and biomass material technology, applied in the field of biomass fiber-based three-dimensional porous materials and its preparation, can solve problems such as the inability to establish an effective cross-linked network structure, difficulty in controlling the material structure, and poor stability of the material structure, achieving a huge The effect of commercial and social value, low cost and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

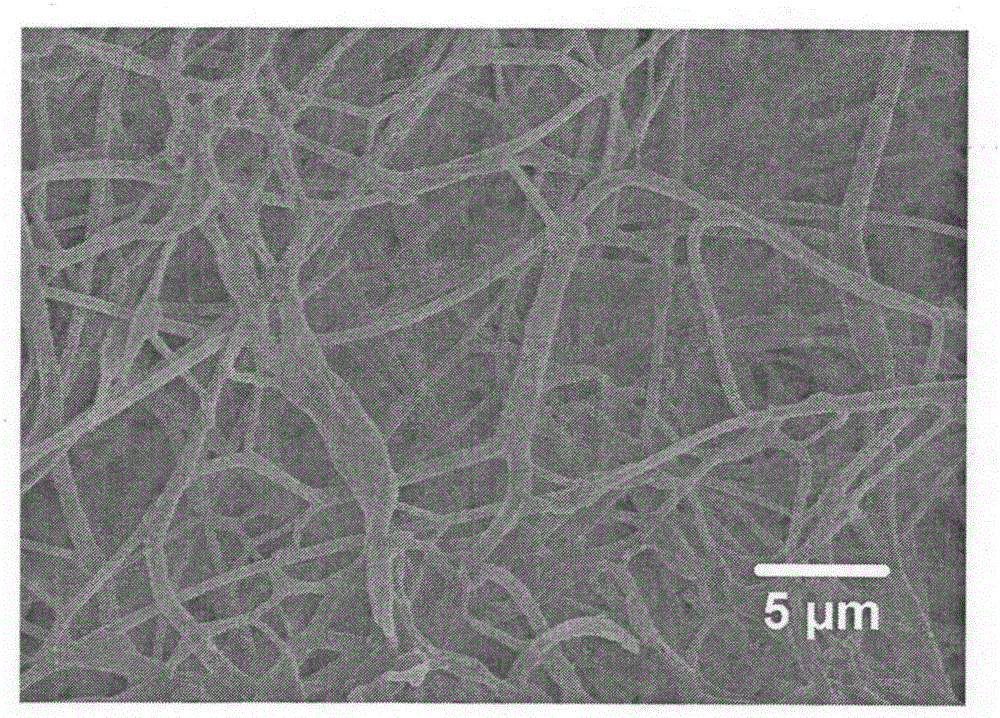

[0029] A biomass fiber-based three-dimensional porous material includes biomass fibers, and the biomass fibers are mutually cross-linked and supported to form a three-dimensional network structure. Its preparation method is:

[0030] The first step: using plant biomass material straw as raw material, screening the straw with a diameter of 15 μm and an aspect ratio of 500, and cleaning it;

[0031] The second step: activate the straw obtained after the first step, specifically: soak it in a sodium hydroxide solution with a mass fraction of 2%, heat it in an oil bath at 100°C for 2 hours, and take it out Afterwards, wash repeatedly with deionized water until neutral;

[0032] The third step: use the oxidized starch in the starch as a biological cross-linking agent, prepare an oxidized starch solution with a mass fraction of 0.01%, and the solvent is ethanol, and disperse the treated straw in the oxidized starch solution, using Shanghai Zhenxuan Electromechanical Co., Ltd. Orie...

Embodiment 2

[0035] A biomass fiber-based three-dimensional porous material includes biomass fibers, and the biomass fibers are mutually cross-linked and supported to form a three-dimensional network structure. Its preparation method is:

[0036] The first step: using plant biomass material ramie as raw material, screening ramie fibers with a single fiber diameter of 30 μm and an aspect ratio of 6, and cleaning;

[0037] The second step: activate the ramie treated in the first step, specifically: soak it in a dilute sulfuric acid solution with a mass fraction of 2%, heat it in a water bath and keep it at 50°C for 2 hours, take it out and use a deionized Repeatedly wash with water until neutral, then treat with 0.05% sodium hydroxide solution, and keep it in an oil bath at 120°C for 6 hours, then repeatedly wash with deionized water until neutral;

[0038] The third step: using egg white protein in proteins as a biological cross-linking agent, prepare an egg white solution with a mass frac...

Embodiment 3

[0041]A biomass fiber-based three-dimensional porous material includes biomass fibers, and the biomass fibers are mutually cross-linked and supported to form a three-dimensional network structure. Its preparation method is:

[0042] The first step: using animal biomass material silk as raw material, screening silk with a diameter of 14 μm and an aspect ratio of 500, and cleaning;

[0043] The second step: Activate the silk treated in the first step, specifically: soak it in a dilute sulfuric acid solution with a mass fraction of 2%, heat it in a water bath and keep it at 100°C for 1 hour, take it out and use deionized Rinse with water repeatedly until neutral;

[0044] Step 3: Use pectin in gums as a biological cross-linking agent to prepare a pectin solution with a mass fraction of 20%, and the solvent is ethanol, and disperse the treated silk in the pectin solution, using Shanghai Zhenxuan Electromechanical Co., Ltd. Orientation high-speed beating machine with frequency co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com