Method for making controllable curved holes through femtosecond lasers with assistance of electric field

A femtosecond laser and electric field-assisted technology, which is applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problem of chaotic bending holes, and achieve the effect of low price, stable properties and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] Embodiment: A femtosecond laser is used to prepare a curved hole array on an alumina material with a thickness of 100 um.

[0028] 1. Pretreat the selected alumina material, and ultrasonically clean it in acetone, absolute ethanol, and deionized water for 5 minutes respectively.

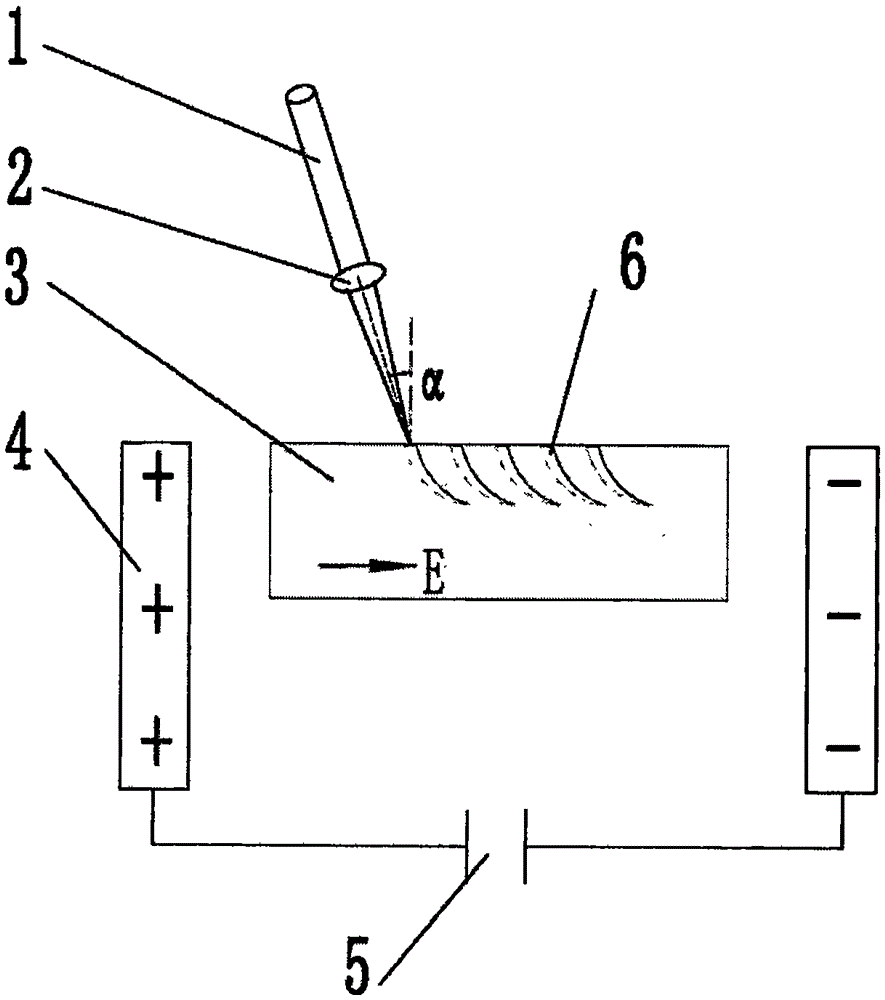

[0029] Two, as attached figure 1 As shown, the cleaned alumina material 3 is placed on a six-degree-of-freedom translation stage, the femtosecond laser 1 with a center wavelength of 800 nm, a pulse width of 50 fs, and a repetition rate greater than 100 Hz passes through a 5X objective lens 2 with a focal length of 200 mm and a vertical Focus on the surface of the material at an angle of α in the straight direction, control the voltage of the high-voltage DC voltage source 5, that is, control the voltage at both ends of the electrode plate 4, and process an array of curved holes 6 on the surface of the material, and control the single pulse energy of the femtosecond laser 1 to 300uJ , the numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com