Multi-level pore material

A porous material and multi-level pore technology, applied in the field of porous materials, can solve problems such as irregularities, affecting functions, and insufficient uniformity, and achieve the effects of good penetration, meeting functional requirements, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The multi-level porous material in this embodiment is porous alumina, which has a secondary pore structure, wherein the uniformly distributed and interpenetrating first-level cavities have uniformly distributed and inter-connecting second-level cavities on the wall of the cavity, and The two levels of pores are also connected to each other. The above-mentioned penetration is three-dimensional. Each level of porous material is a continuous structure. The maximum outer boundary of each level of porous material is equivalent to the space boundary of the entire material body. Each level of porous material has Unique physical and chemical properties. The total effective porosity is 60%, the average pore diameter of the large pores is 10 μm, and there are through small pores with an average pore diameter of 750 nm on the wall of the large pores.

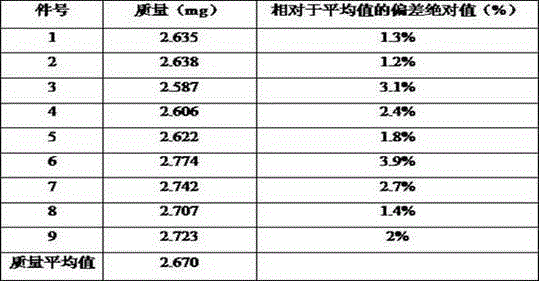

[0027] Nine pieces of 10mm×10mm×10mm three-dimensional bodies of the same size were randomly taken from the multi-level porous mat...

Embodiment 2

[0038]The multi-level porous material of this embodiment is porous nickel, has a secondary pore structure, and is graded according to the material pore size. The pores of each level and the pores of each level are three-dimensionally connected, and each level of porous material is a continuous structure. , the maximum outer boundary of each level of porous material is equivalent to the space boundary of the entire material body, and each level of porous material has its own physical and chemical properties. The total effective porosity is 70%, the average pore diameter of the large pores is 30 μm, and there are through small pores with an average pore diameter of 600 nm on the wall of the large pores.

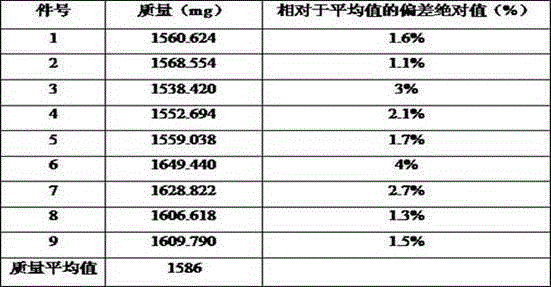

[0039] Take 9 three-dimensional bodies of the same size of 1mm×1mm×1mm on the multi-level porous material by mechanical processing method, and use the Mettler-Toledo XP26 Microbalance balance to test its quality. The results are shown in Table 2. Among them, relative The absolu...

Embodiment 3

[0050] The multi-stage porous material in this embodiment is porous tantalum, which has three-stage pores, wherein the uniformly distributed and interpenetrating first-stage cavities have second-stage cavities evenly distributed and interpenetrating on the cavity wall, and the second-stage cavities There are evenly distributed third-level cavities on the wall of the cavity, and the cavities of each level are also connected to each other, and the above-mentioned perforation is a three-dimensional perforation. Each level of porous material is a continuous structure, the largest outer boundary of each level of porous material is equivalent to the space boundary of the entire material body, and each level of porous material has its own physical and chemical properties. The total effective porosity is 80%, the average pore diameter of the first-stage pores is 510 μm, there are second-stage pores with an average pore diameter of 25 μm on the cavity wall of the first-stage pores, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com