High uniformity glass fiber liquid filtration material and preparation method thereof

A glass fiber and filter material technology, which is applied in the field of high uniformity glass fiber liquid filter material and its preparation, can solve the problems of different pore size and poor uniformity of filter material, etc., to improve forming uniformity and improve production process capability control. , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Mix flame-blown microfiber glass wool, centrifugally rotating microfiber glass wool, glass fiber chopped strands with water and inorganic acid to make a pulp suspension. The concentration of the suspension is 1.0 wt%, and the pH value is 3. The inorganic acid used Be dilute hydrochloric acid; After deslagging and dilution (suspension concentration after dilution is 0.18wt%), send to Fourdrinier to form wet paper sheets with uniform thickness; Water-soluble acrylic binder (Shanghai Motian Chemical, model LD909) is diluted with water to a concentration of 3wt%, sprayed evenly or overflowed on wet paper, dried at 150°C for 50min, and the weight is 75g / m 2 Glass fiber liquid filter substrate, glass fiber filter substrate and non-woven fabric (gram weight is 50g / cm 2 ) compound on one side to obtain a liquid filter material.

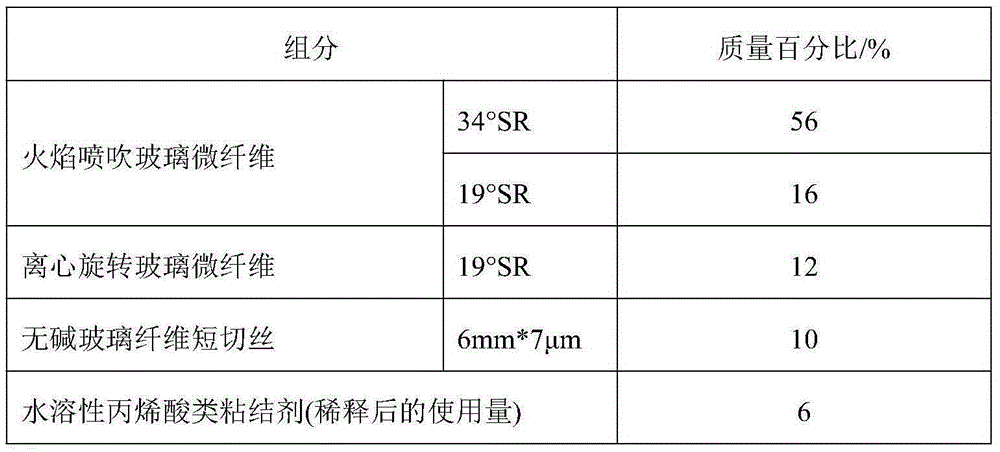

[0039] See Table 1 for the mass percent of each component in the above-mentioned glass fiber liquid filter material.

[0040] The raw material compo...

Embodiment 2

[0043]Stir the flame-blown microfiber glass wool, glass fiber chopped strands, water and inorganic acid to make a pulp suspension evenly; after deslagging and dilution, send it to the fourdrinier machine to form a wet paper sheet with uniform thickness; Glue and drying process, the obtained grammage is 75g / m 2 The base material of the glass fiber liquid filter material, and then combined with the non-woven fabric on one side to obtain the liquid filter material. The difference between Example 2 and Example 1 is that no centrifugal rotating microfiber glass wool is added to the raw materials, and the mass percentages of each component in the glass fiber liquid filter material are shown in Table 2, and others refer to Example 1.

[0044] The raw material component mass percentage of glass fiber liquid filter material in the embodiment 2 of table 2

[0045]

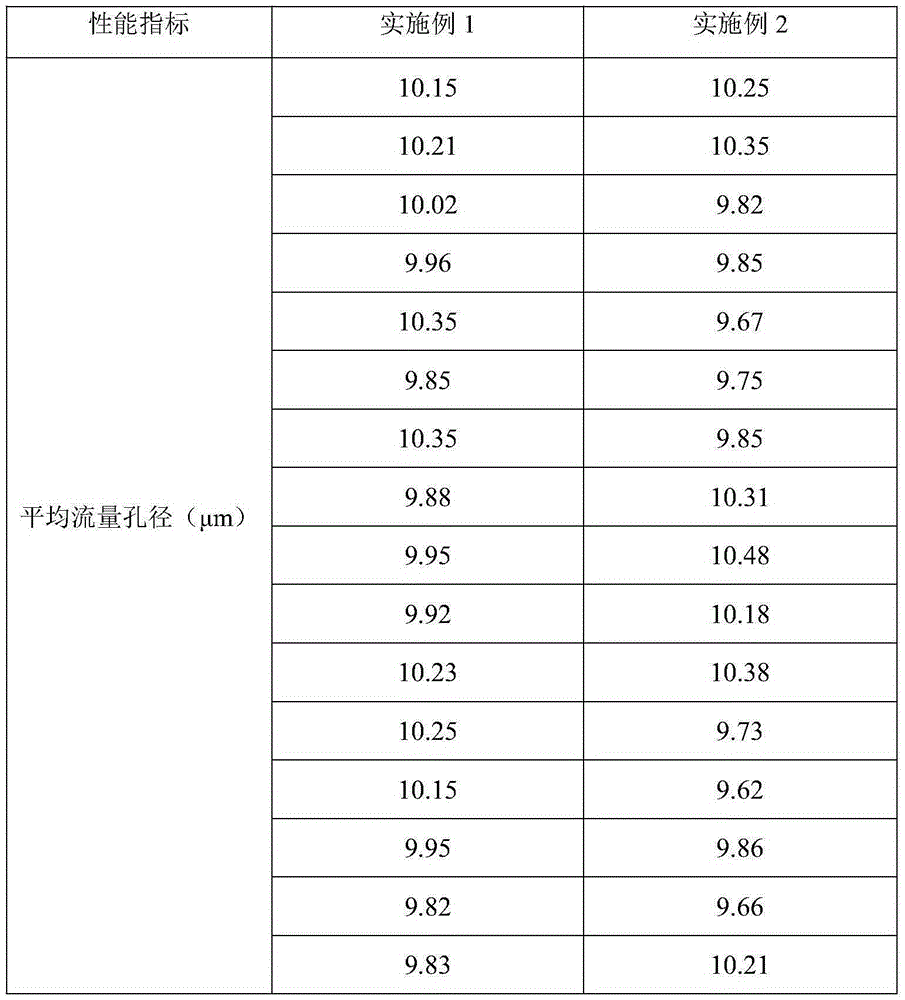

[0046] The performance test results of the liquid filter materials prepared in Example 1 and Example 2 are shown in Ta...

Embodiment 3

[0052] Mix flame-blown microfiber glass wool, centrifugally rotating microfiber glass wool, glass fiber chopped strands with water and inorganic acid to make a pulp suspension. The concentration of the suspension is 1.1wt%, and the pH value is 3. The inorganic acid used Be dilute sulfuric acid; After deslagging and dilution (suspension concentration after dilution is 0.15wt%), send to Fourdrinier to form wet paper sheets with uniform thickness; Water-soluble acrylic binder (Shanghai Motian Chemical, model LD909) was diluted with water to a concentration of 6wt%, sprayed evenly or overflowed onto wet paper, dried at 180°C for 30min, and obtained a grammage of 75g / m 2 Glass fiber liquid filter substrate, glass fiber filter substrate and non-woven fabric (weight is 35g / cm 2 ) double-sided composite to obtain a liquid filter material.

[0053] See Table 4 for the mass percent of each component in the above-mentioned glass fiber liquid filter material.

[0054] The raw material c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Knocking degree | aaaaa | aaaaa |

| Knocking degree | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com