Has multi-level porous ssz-13 molecular sieve catalyst and its synthesis method and application

A synthesis method and molecular sieve technology, which are applied to molecular sieve catalysts, including molecular sieve catalysts, molecular sieves and alkali exchange compounds, etc., can solve the problems of molecular sieve catalytic life limitation and large molecular sieve particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

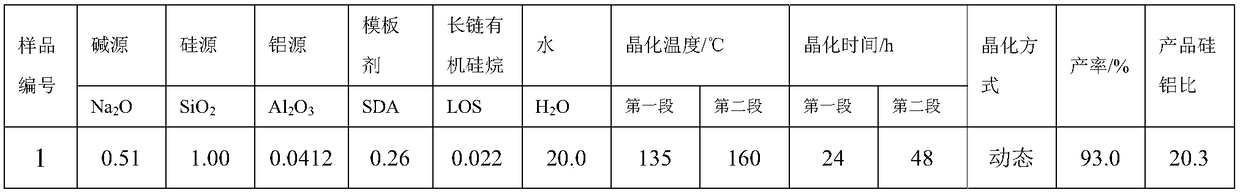

Embodiment 1

[0028] According to the ratio listed in Table 1, the ratio of the reaction raw materials was weighed and the quantitative long-chain organosilane was dissolved in methanol to form a solution and stirred to disperse, then the silicon source and the alkali source were added, and stirred at 40°C for 6 hours.

[0029] A silicon source mixed solution was obtained; at 60° C., the aluminum source solution was added dropwise to the silicon source mixed solution according to the ratio of the reaction raw materials, and after vigorous stirring for 90 minutes, the mixture was left to age for 12 hours to obtain a mixture gel. Place the mixture gel in a hydrothermal synthesis kettle at 120-190°C for crystallization in two stages, the temperature of the second stage is 20°C higher than that of the first stage, after the crystallization is complete, centrifuge to separate the solid product, and then use the solid product Repeated washing with deionized water until neutral, then drying at 120°...

Embodiment 2

[0037]The SSZ-13 molecular sieve samples 1-20 synthesized in Example 1 were characterized and analyzed using a Micromeritics ASAP 2020 nitrogen physical adsorption instrument. The pretreatment method of the sample before analysis is as follows: vacuumize the molecular sieve sample at room temperature, and when the vacuum condition is reached, treat it at 130°C for 2h; then treat it at 350°C for 2h. The nitrogen physical adsorption results show that samples 1-20 have a micropore diameter of 0.3-0.5 nm, and all contain mesopore diameter distribution, mesopore average pore diameter, mesopore volume and specific surface area as shown in Table 3.

[0038] table 3

[0039]

[0040]

Embodiment 3

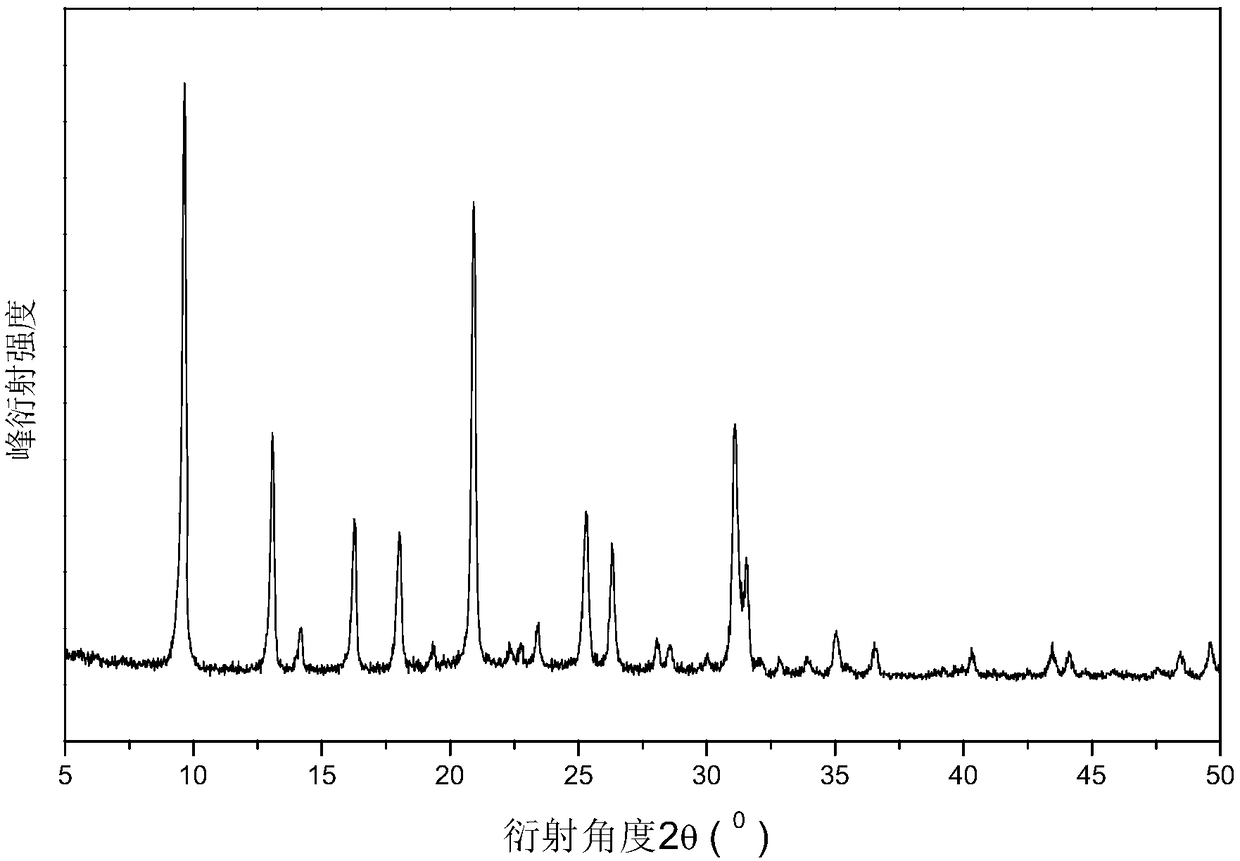

[0042] Samples 1-20 prepared in Example 1 were characterized by XRD to confirm that they were SSZ-13 molecular sieves. The instrument used is a PANalytical X’Pert X-ray diffractometer, a copper target, and a Kα radiation source. The operating voltage of the instrument is 40kv, and the operating current is 40mA. The obtained XRD spectrum of samples 1-20 and the characteristic spectrum of standard SSZ-13 molecular sieve Figure 1 Sincerely. Typical XRD patterns (such as figure 1 ) is represented by sample 1, and the positions and peak intensities of the main diffraction peaks at 2θ between 5° and 50° are shown in Table 4. Compared with sample 1, other sample data results have the same diffraction peak position and shape, and the relative peak intensity fluctuates within ±5% according to the change of synthesis conditions, indicating that the synthesized product has the characteristics of SSZ-13 molecular sieve structure.

[0043] Table 4

[0044]

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com