Method for preparing near-zero-thickness nanopores by double-sided helium ion beam etching as well as product and application of near-zero-thickness nanopores

A technology of ion beam etching and nanopore, applied in nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of insufficient time resolution of nanopores, low capture rate of nanopores, unsuitable for mass production and application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

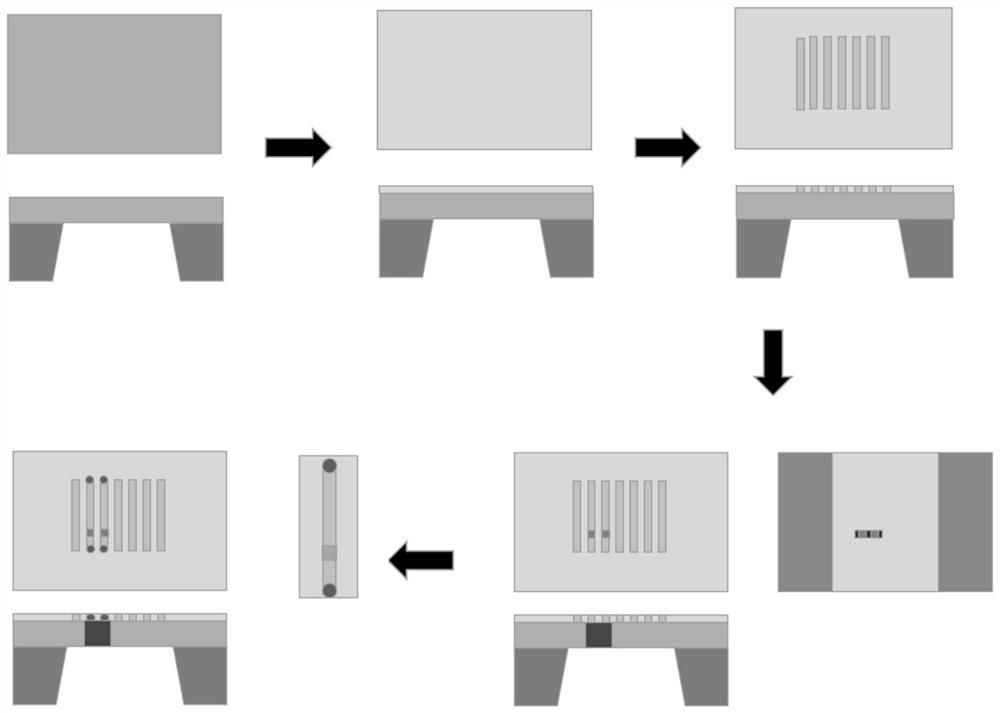

[0040] To prepare near-zero-thickness nanopores with a single-pore structure, the preparation process is specifically carried out according to the following steps:

[0041] 1. Select a silicon substrate with a thickness of 10-20 μm, and grow a layer of silicon nitride material with a thickness of 30 nm on the silicon substrate by chemical vapor deposition to obtain a silicon-based film substrate.

[0042] 2. Etching the silicon substrate surface of the silicon-based thin-film substrate by chemical wet etching to form a thin-film window with a side length of 20 μm, that is, to obtain a silicon-based thin-film substrate with a thin-film window.

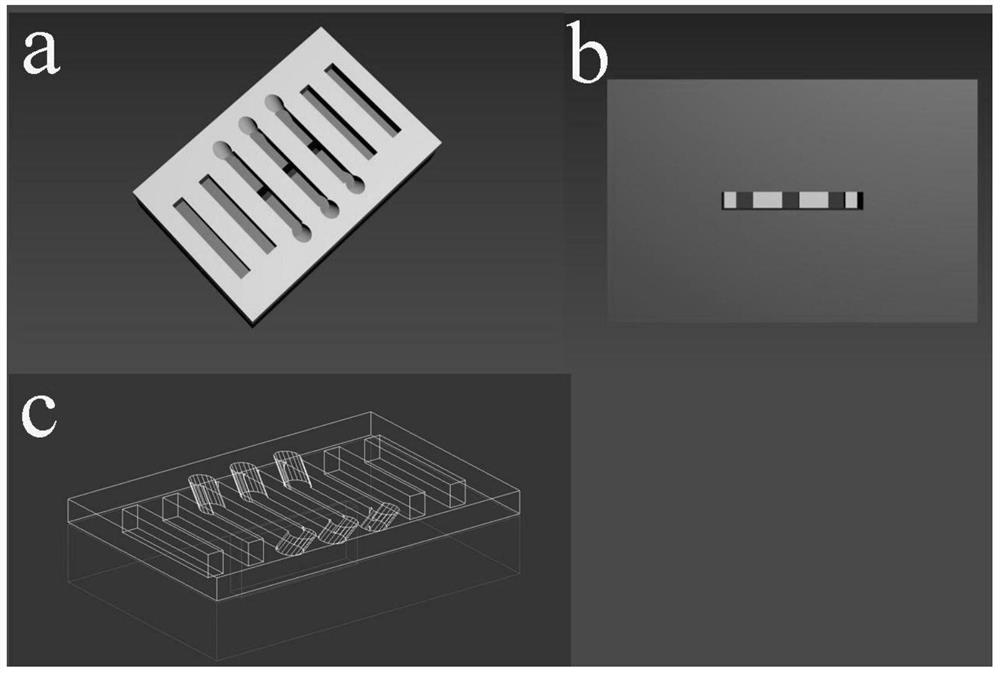

[0043] 3. Use helium ion beam etching on one side (front) of the silicon nitride material (etching parameters are set to: aperture 10μm, beam current less than or equal to 1pA, dose 100-300nc / μm 2 ) to form a row of vertical nanowire arrays with a length of 200nm, a width of 4nm, a depth of 10nm, and a period of 500nm.

[0044] 4. On t...

Embodiment 2

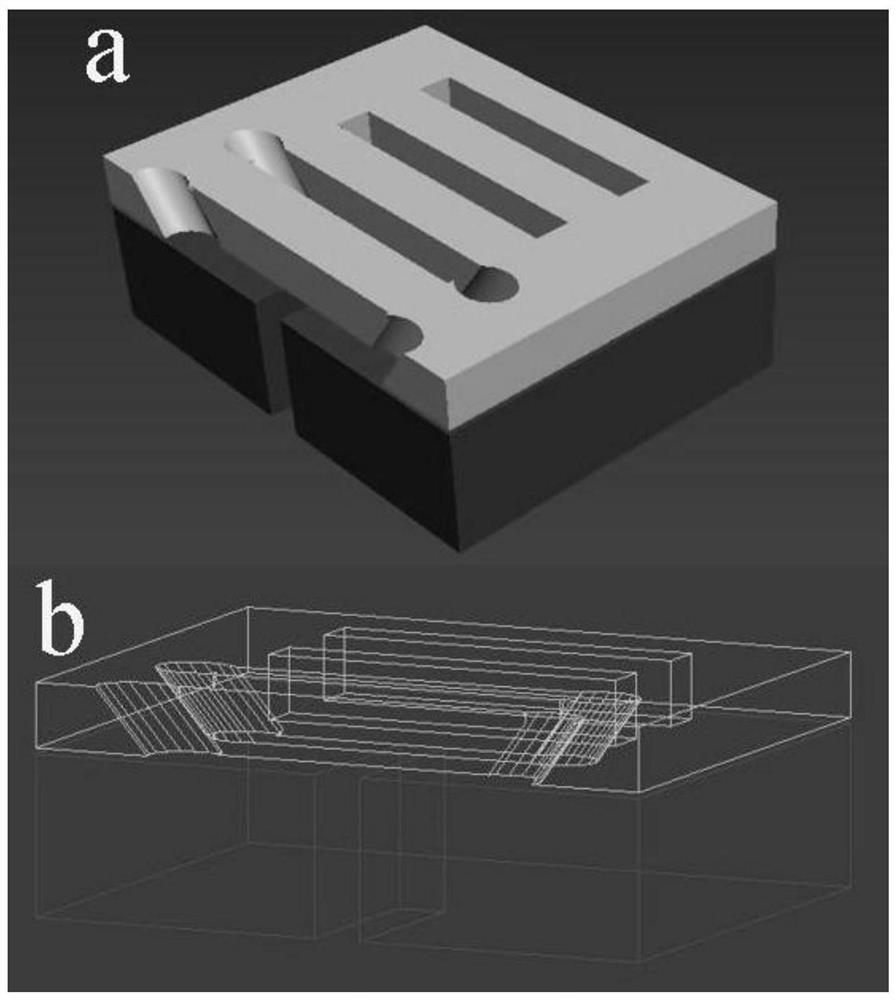

[0049] The preparation process of near-zero-thickness nanopores with double-pore structure is as follows:

[0050] 1. Select a silicon substrate with a thickness of 10-20 μm, first grow a layer of silicon dioxide material with a thickness of 200 nm on the silicon substrate by chemical vapor deposition, and then use chemical vapor deposition to grow a layer of silicon dioxide on the silicon dioxide. A silicon nitride material with a layer thickness of 20nm is obtained to obtain a silicon-based film substrate.

[0051] 2. Etching the silicon substrate surface of the silicon-based thin-film substrate by chemical wet etching to form a thin-film window with a side length of 20 μm, that is, to obtain a silicon-based thin-film substrate with a thin-film window.

[0052] 3. Use helium ion beam etching on one side (front) of the silicon nitride material (etching parameters are set to: aperture 10μm, beam current less than or equal to 1pA, dose 100-300nc / μm 2 ) to form a row of vertica...

Embodiment 3

[0058] To prepare near-zero thickness nanopores, the preparation process is as follows:

[0059] 1. Select a silicon substrate with a thickness of 10-20 μm, first grow a layer of silicon nitride material with a thickness of 20 nm on the silicon substrate by chemical vapor deposition, and then use chemical vapor deposition to grow a layer of silicon nitride on the silicon nitride. Aluminum oxide material with a layer thickness of 100nm to obtain a silicon-based film substrate.

[0060] 2. Etching the silicon substrate surface of the silicon-based thin-film substrate by chemical wet etching to form a thin-film window with a side length of 20 μm, that is, to obtain a silicon-based thin-film substrate with a thin-film window.

[0061] 3. Use helium ion beam etching on one side (front) of the silicon nitride material (etching parameters are set to: aperture 10μm, beam current less than or equal to 1pA, dose 100-500nc / μm 2 ) for processing (at this time, the choice to process the n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com