Three-dimensional porous graphene aerogel wave-absorbing material and preparation method thereof

A graphene airgel and graphene hydrogel technology, which is applied in the direction of airgel preparation, graphene, chemical instruments and methods, etc., can solve the problems of complex preparation process, increased density of absorbing materials, and uneven pore size distribution , to achieve the effect of simple process, ultra-low filling amount and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

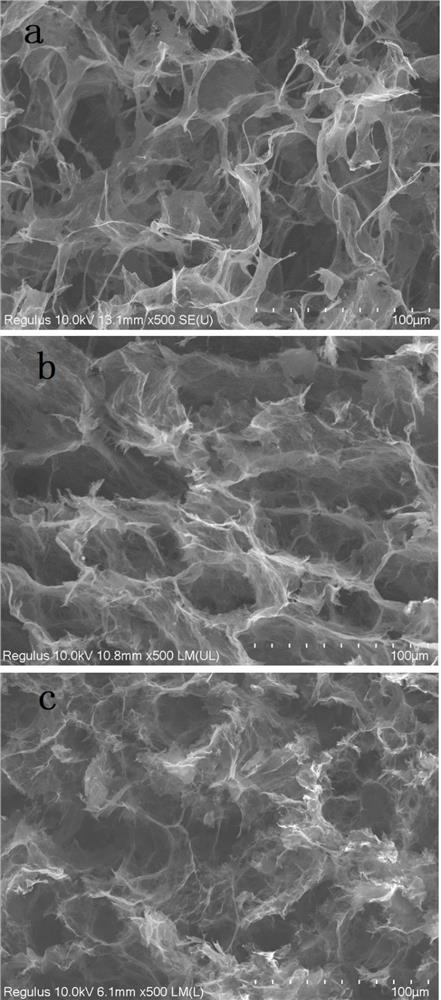

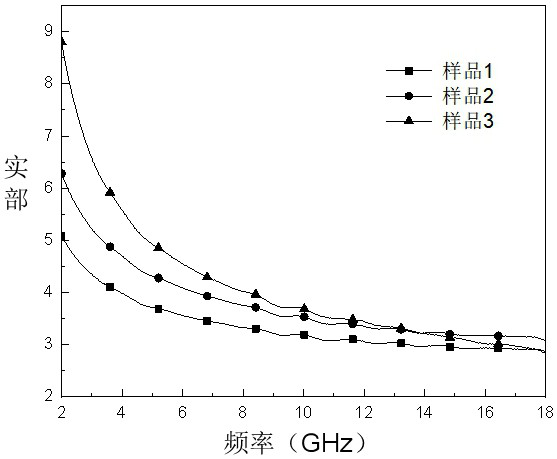

[0025] Graphene oxide aqueous solution (3 mg / ml, 2ml), ascorbic acid (18mg) and ethanol (20mL) were measured, stirred by magnetic force, and dispersed ultrasonically in cold water to obtain a mixed solution. The mixed solution was transferred to a glass bottle and sealed, and placed in a 50°C oven for pre-reduction for 15 minutes to obtain a pre-reduced graphene hydrogel. The pre-reduced graphene hydrogel was frozen at -30 °C for 60 min, and then thawed at room temperature for 30 min to obtain the freeze-thawed pre-reduced graphene hydrogel. The freeze-thawed pre-reduced graphene hydrogel was sealed and placed in an oven at 95°C for 4 hours to obtain the graphene hydrogel. Put the hydrogel in an ethanol / water mixed solution (the volume ratio of ethanol and water is 1:4) and age for 24 h, then freeze at -60°C for 12 h, take it out and dry it in a freeze-drying equipment for 24 h. h, Obtained three-dimensional graphene airgel (sample 1). The prepared graphene airgel has a dens...

Embodiment 2

[0027] Measure graphene oxide aqueous solution (5 mg / ml, 2ml), sodium bisulfite (10mg) and methanol (200mL), stir magnetically, and disperse ultrasonically in cold water to obtain a mixed solution. The mixed solution was transferred to a glass bottle and sealed, and placed in an oven at 80 °C for pre-reduction for 120 min to obtain a pre-reduced graphene hydrogel. The pre-reduced graphene hydrogel was frozen at -50 °C for 45 min, and then thawed at room temperature for 45 min to obtain the pre-reduced graphene hydrogel after freeze-thawing. The freeze-thawed pre-reduced graphene hydrogel was sealed and placed in an oven at 80° C. for further reduction for 8 hours to obtain a graphene hydrogel. Put the hydrogel in an ethanol / water mixed solution (the volume ratio of ethanol and water is 1:5) and age for 48 h, then freeze at -60°C for 12 h, take it out and dry it in a freeze-drying equipment for 24 h. h, Obtained three-dimensional graphene airgel (sample 2). The prepared graph...

Embodiment 3

[0029] Measure graphene oxide aqueous solution (1 mg / ml, 2ml), hydriodic acid (10 mg) and isopropanol (100mL), stir magnetically, and disperse ultrasonically in cold water to obtain a mixed solution. The mixed solution was transferred to a glass bottle and sealed, and placed in a 95°C oven for pre-reduction for 60 min to obtain a pre-reduced graphene hydrogel. The pre-reduced graphene hydrogel was frozen at -70 °C for 10 min, and then thawed at room temperature for 60 min to obtain the freeze-thawed pre-reduced graphene hydrogel. The freeze-thawed pre-reduced graphene hydrogel was sealed and placed in an oven at 70 °C for 10 h to obtain graphene hydrogel. Put the hydrogel in an ethanol / water mixed solution (the volume ratio of ethanol and water is 1:6) and age for 72 h, then freeze at -60°C for 12 h, take it out and dry it in a freeze-drying equipment for 24 h. h, Obtained three-dimensional graphene airgel (sample 3). The prepared graphene airgel has a density of 8.50 mg / cm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Minimum reflection loss | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Minimum reflection loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com