A kind of multilevel core-shell structure lithium extraction material and preparation method thereof

A core-shell structure and composite material technology, applied in chemical instruments and methods, other chemical processes, alkali metal compounds, etc., can solve the problems of restricting the application of materials, difficult separation and recycling, and achieve low cost, avoid wear and consumption, The effect of preventing the problem of dissolution loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method for a lithium-extracting material with a multi-level core-shell structure, comprising the steps of:

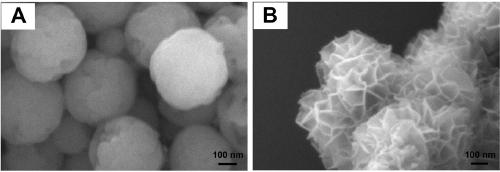

[0027] (1) Hydrothermal reaction: prepare 60 mL of potassium permanganate solution with a concentration of 0.04 g / mL, mix 0.5 g of TiO with a particle size of 500 nm 2 The microspheres were added to the above potassium permanganate solution, and after ultrasonic stirring for 30 min, the mixed solution was poured into a polytetrafluoroethylene-lined stainless steel reaction kettle, heated at 150°C for 40 h, cooled, filtered, and washed with distilled water for 3 ~6 times, drying at 80°C for 12 h to obtain TiO with core-shell structure 2 @MnO 2 composite materials;

[0028] (2) Solid phase reaction: TiO with core-shell structure prepared by the above hydrothermal method 2 @MnO 2 The composite material is the precursor, LiOH and TiO 2 @MnO 2 After the manganese in the composite material was mixed in a molar ratio of 1:2, the resulting mixture was...

Embodiment 2

[0032] A preparation method for a lithium-extracting material with a multi-level core-shell structure, comprising the steps of:

[0033] (1) Hydrothermal reaction: Prepare 60 mL of potassium permanganate solution with a concentration of 0.05 g / mL, and mix 0.5 g of TiO with a particle size of 400 nm 2 The microspheres were added to the above potassium permanganate solution, and after ultrasonic stirring for 30 min, the mixed solution was poured into a polytetrafluoroethylene-lined stainless steel reaction kettle, heated at 150°C for 40 h, cooled, filtered, and washed with distilled water for 3 ~6 times, drying at 80°C for 12 h to obtain TiO with core-shell structure 2 @MnO 2 composite materials;

[0034] (2) Solid phase reaction: TiO with core-shell structure prepared by the above hydrothermal method 2 @MnO 2 The composite material is the precursor, LiOH and TiO 2 @MnO 2 After the manganese in the composite material was mixed in a molar ratio of 1:2, the resulting mixture...

Embodiment 3

[0038] A preparation method for a lithium-extracting material with a multi-level core-shell structure, comprising the steps of:

[0039] (1) Hydrothermal reaction: prepare 60 mL of potassium permanganate solution with a concentration of 0.04 g / mL, mix 0.5 g of TiO with a particle size of 500 nm 2 The microspheres were added to the above potassium permanganate solution and stirred ultrasonically for 30 min. Pour the mixed solution into a polytetrafluoroethylene-lined stainless steel reaction kettle, heat it in water at 150 °C for 40 h, cool, filter, wash with distilled water for 3 to 6 times, and dry at 80 °C for 12 h to obtain TiO with a core-shell structure. 2 @MnO 2 composite materials;

[0040] (2) Solid phase reaction: TiO with core-shell structure prepared by the above hydrothermal method 2 @MnO 2 The composite material is the precursor, LiOH and TiO 2 @MnO 2 After the manganese in the composite material was mixed at a molar ratio of 1:3, the resulting mixture was t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com