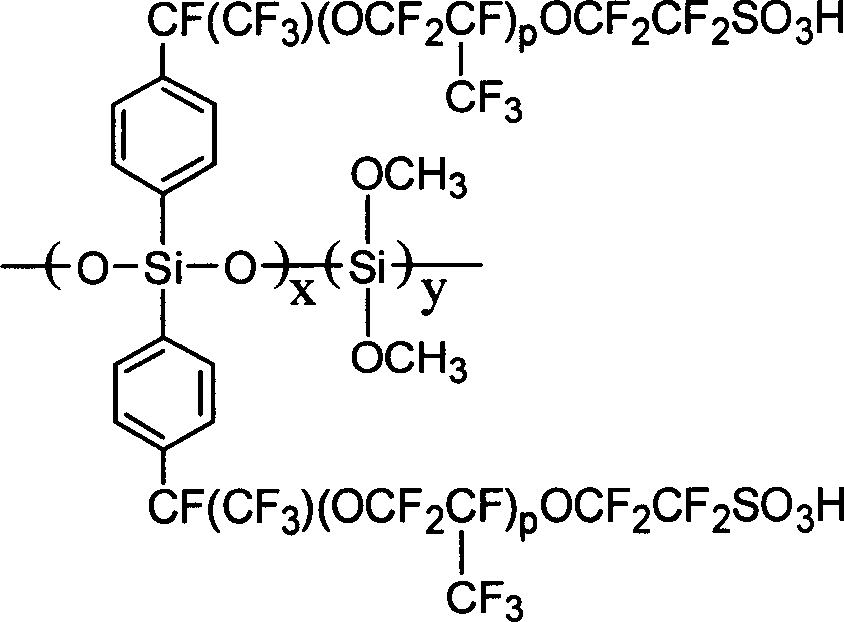

Fluorine contained silicon dioxide hybridized material and preparation process thereof

A technology of hybrid materials and silicon dioxide, which is applied in the field of functional hybrid materials and their preparation, can solve the problems that are difficult to be widely used, and achieve the effects of large surface area, mild synthesis conditions and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) CClF of perfluoro-2-(2-fluorosulfonyl-ethoxy)propionyl peroxide 2 CCl 2 Preparation of solution F: immerse a 100ml reaction bottle in an ice-salt bath at -15°C, and add 8.0ml of 10wt% sodium hydroxide aqueous solution, 1.15ml of 30wt% hydrogen peroxide and 50ml of CCl under slow stirring 2 FCClF 2 , after stirring for 5 minutes, quickly added 6.92g of perfluoro-2-(2-fluorosulfonyl-ethoxy) propionyl fluoride FO 2 SCF2 CF 2 OCF (CF 3 ) COF, the reaction was carried out for 2 minutes, then the stirring was stopped, and the reaction mixture was separated completely, and the oil layer was successively washed with 5wt% NaHCO 3 After washing with aqueous solution and distilled water, add anhydrous sodium sulfate, shake well for several minutes, and stand in an ice bath for 30 minutes to obtain perfluoro-2-(2-fluorosulfonyl-ethoxy)propionyl peroxide CCIF 2 CCl 2 F solution;

[0030] 2) Preparation of p-perfluoro-[1-(2-fluorosulfonyl)ethoxy]ethyl-substituted polydiphe...

Embodiment 2

[0036] 1) CClF of perfluoro-{2-[2-(2-fluorosulfonyl-ethoxy)propoxy]}propionyl peroxide 2 CCl 2 Preparation of F solution: Fill with 50ml CClF 2 CCl 2 Immerse the 100ml reaction bottle of F in an ice-salt bath at -15°C, add 3.12g of sodium peroxide and 10.24g of perfluoro-{2-[2-(2-fluorosulfonyl-ethoxy) under slow stirring )propoxyl]}propionyl fluoride FO 2 SCF 2 CF 2 OCF (CF 3 ) CF 2 OCF (CF 3 ) COF, stop the reaction after continuing to stir for 2 minutes, make the reaction mixture layered completely, and the oil layer is successively washed with 5wt%NaHCO 3 After washing with aqueous solution and distilled water, add anhydrous sodium sulfate, shake well for a few minutes, and stand in an ice bath for 30 minutes to obtain perfluoro-{2-[2-(2-fluorosulfonyl-ethoxy)propoxy) CClF of propionyl peroxide 2 CCl 2 F solution;

[0037] 2) Preparation of p-perfluoro-{1-[2-(2-fluorosulfonyl-ethoxy)propoxy]}ethyl substituted polydiphenyldimethoxysilane: in a 150ml three-necked...

Embodiment 3

[0042] 1) CClF of perfluoro-2-(2-fluorosulfonyl-ethoxy)propionyl peroxide 2 CCl 2 Preparation of solution F: immerse a 100ml reaction bottle in an ice-salt bath at -15°C, and add 8.0ml of 10wt% sodium hydroxide aqueous solution, 1.15ml of 30wt% hydrogen peroxide and 50ml of CCl under slow stirring 2 FCClF 2 , after stirring for 5 minutes, quickly added 6.92g of perfluoro-2-(2-fluorosulfonyl-ethoxy) propionyl fluoride FO 2 SCF 2 CF 2 OCF (CF 3 ) COF, the reaction was carried out for 2 minutes, then the stirring was stopped, and the reaction mixture was separated completely, and the oil layer was successively washed with 5wt% NaHCO 3 After washing with aqueous solution and distilled water, add anhydrous sodium sulfate, shake well for several minutes, and stand in an ice bath for 30 minutes to obtain perfluoro-2-(2-fluorosulfonyl-ethoxy)propionyl peroxide CCIF 2 CCl 2 F solution;

[0043] 2) Preparation of p-perfluoro-[1-(2-fluorosulfonyl)ethoxy]ethyl-substituted polydip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com