Composite-structure molecular sieve and synthetic method thereof

A technology of composite structure and synthesis method, applied in molecular sieve catalysts, chemical instruments and methods, crystalline aluminosilicate zeolite, etc., can solve the problems of single pore size, low activity, weak acidity, etc., and achieve good stability and good catalysis. The effect of performance, good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

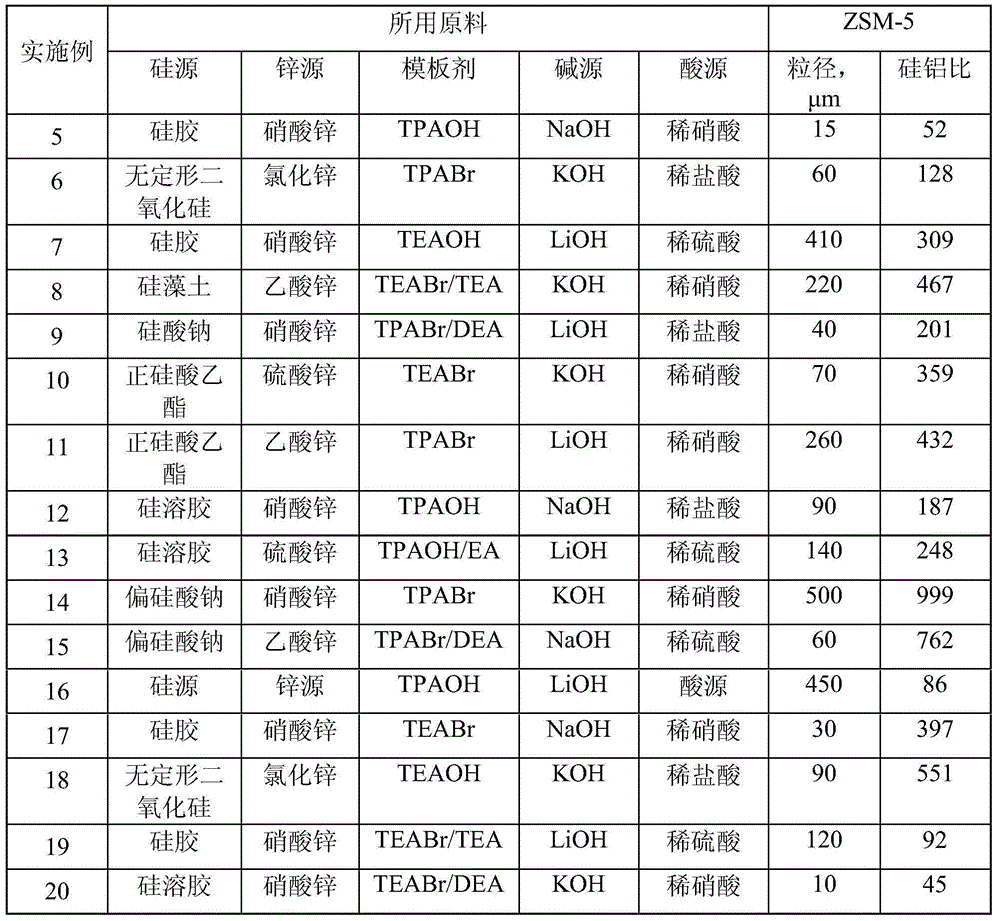

Examples

Embodiment 1

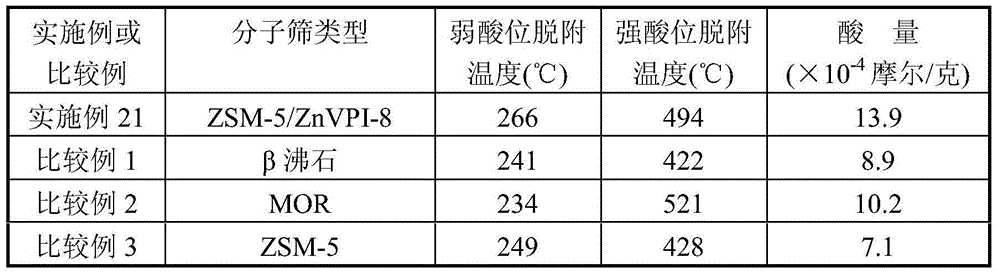

[0031] Synthesis of ZSM-5 / ZnVPI-8 Composite Molecular Sieve

[0032] Take 94.7 grams of sodium metasilicate and 15.5 grams of sodium hydroxide, dissolve it with 380 grams of distilled water to form solution A, take 21 grams of zinc nitrate, and make solution B with 35 grams of distilled water, slowly pour solution B into solution A, and stir vigorously , then add 9.8 gram of tetraethylammonium hydroxide and 4.2 gram of ethylenediamine (mixed templating agent is denoted as M), after stirring for a period of time, adjust the pH value at 11 with dilute sulfuric acid, control the molar ratio of the crystallization mixed solution as : SiO 2 :ZnO:NaOH:M:H 2 O=1:0.1:0.5:0.4:30, add 1.0 g ZSM-5 zeolite seed (SiO 2 / Al 2 o 3 =50, the grain size is 100nm), put the mixed solution in an autoclave, keep it warm at 120°C for 100 hours, take it out, wash it with water, wash it with alcohol twice, dry it at 120°C for 6 hours, and roast it at 550°C for 6 hours to obtain ZSM-5 / ZnVPI-8 comp...

Embodiment 2

[0034] Synthesis of ZSM-5 / ZnVPI-8 Composite Molecular Sieve

[0035] Take 245 grams of sodium metasilicate and 2.4 grams of lithium hydroxide, dissolve it with 2000 grams of distilled water to form solution A, take 542 grams of zinc nitrate, and make solution B with 1600 grams of distilled water, slowly pour solution B into solution A, and stir vigorously , then add 2101 grams of tetraethylammonium bromide (template agent is denoted as M), after stirring for a period of time, adjust the pH value at 9 with dilute nitric acid, and the molar proportion of the control crystallization mixed solution is: SiO 2 :ZnO:LiOH:M:H 2 O=1:1:0.05:5:100, add 5.0 g of ZSM-5 zeolite seed crystals (SiO 2 / Al 2 o 3 =20, the grain size is 300nm), put the mixed solution in an autoclave, keep it warm at 80°C for 200 hours, take it out, wash it with water, wash it with alcohol twice, dry it at 120°C for 6 hours, and roast it at 550°C for 6 hours to obtain ZSM-5 / ZnVPI-8 composite molecular sieve (w...

Embodiment 3

[0037] Synthesis of ZSM-5 / ZnVPI-8 Composite Molecular Sieve

[0038] Take 189.4 grams of sodium metasilicate and 80 grams of sodium hydroxide, dissolve it with 1400 grams of distilled water to form solution A, take 210 grams of zinc nitrate, and make solution B with 400 grams of distilled water, slowly pour solution B into solution A, and stir vigorously , then add 84 grams of tetraethylammonium bromide and 25.2 grams of ethylenediamine (the mixed template is denoted as M), after stirring for a period of time, adjust the pH value at 12 with dilute sulfuric acid, and control the molar proportion of the crystallization mixed solution as : SiO 2 :ZnO:NaOH:M:H 2 O=1:1:0.5:2.4:50, add 2.5 grams of ZSM-5 zeolite seed crystals (SiO 2 / Al 2 o 3 =200, the grain size is 30nm), put the mixed solution in an autoclave, keep it warm at 160°C for 54 hours, take it out, wash it with water, wash it with alcohol twice, dry it at 120°C for 6 hours, and roast it at 550°C for 6 hours to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com