SAPO-34/ZSM-5 composite molecular sieve and synthesis method of composite molecular sieve

A composite molecular sieve, ZSM-5 technology, applied in the direction of molecular sieve and alkali exchange phosphate, etc., can solve the problems of low reactivity, weak acidity, single pore size of porous materials, etc., and achieve high reactivity, good technical effect, wide acid distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Weigh 14.7g of pseudo-boehmite and mix it with 78g of water, add 18.5g of orthophosphoric acid (85%) under stirring conditions, continue stirring evenly, add 9g of silica sol (40%), 10g of triethylamine and 10g of Tetraethylammonium hydroxide, stir evenly;

[0031] (2) Weigh 15g of H-type ZSM-5 molecular sieve, add it to the mixture obtained in step (1), and stir evenly;

[0032] (3) Transfer the mixed solution obtained in step (2) to a closed high-pressure crystallization kettle, and crystallize at 180°C for 48 hours;

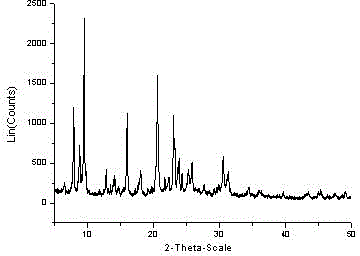

[0033] (4) The product was taken out, washed with water, dried, and calcined at 550°C for 4 hours to remove the template agent to obtain SAPO-34 / ZSM-5 composite molecular sieve, which was quantified by XRD diffraction. The weight content of SAPO-34 molecular sieve in the product was 60%, ZSM The weight content of -5 molecular sieve is 40%, and the XRD diffraction pattern of composite molecular sieve is as follows figure 1 shown.

[0034]

Embodiment 2

[0036](1) Weigh 14.7g of pseudo-boehmite and mix it with 100g of water, add 23g of orthophosphoric acid (85%) under stirring conditions, continue stirring evenly, add 12g of silica sol (40%), 25g of tetraethylammonium hydroxide , stir evenly;

[0037] (2) Weigh 10g of Na-type ZSM-5 molecular sieve, add it to the mixture obtained in step (1), and stir evenly;

[0038] (3) Transfer the mixed solution obtained in step (2) to a closed high-pressure crystallization kettle, and crystallize at 160°C for 60 hours;

[0039] (4) The product was taken out, washed with water, dried, and roasted at 540°C for 5 hours to remove the template agent to obtain a SAPO-34 / ZSM-5 composite molecular sieve, which was quantified by XRD diffraction. The weight content of SAPO-34 molecular sieve in the product was 70%, ZSM The weight content of -5 molecular sieve is 30%.

[0040]

Embodiment 3

[0042] (1) Mix 38g of aluminum isopropoxide with 100g of water, add 25g of orthophosphoric acid (85%), 5g of aluminum dihydrogen phosphate under stirring conditions, continue stirring evenly, add 22g of silica sol (40%), 20g of morpholine And 30g tetraethylammonium hydroxide, stir;

[0043] (2) Weigh 40g of ZSM-5 molecular sieve with Zn ion exchange, add it to the mixed solution obtained in step (1), and stir evenly;

[0044] (3) Transfer the mixed solution obtained in step (2) to a closed high-pressure crystallization kettle, and crystallize at 200°C for 50 hours;

[0045] (4) The product was taken out, washed with water, dried, and roasted at 550°C for 6 hours to remove the template agent to obtain a SAPO-34 / ZSM-5 composite molecular sieve, which was quantified by XRD diffraction. The weight content of SAPO-34 molecular sieve in the product was 40%, ZSM The weight content of -5 molecular sieve is 60%.

[0046] Press and crush the composite molecular sieve, take 9g of 10-20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com