Patents

Literature

52results about How to "Adjustable ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acrylic polyurethane coating and preparation method and application thereof

ActiveCN107216792AGood light transmissionGood light diffusion effectDiffusing elementsPolyurea/polyurethane coatingsPlasticizerAcrylic resin

The invention discloses an acrylic polyurethane coating and a preparation method and application thereof in manufacture of a connecting material or a protective coating. The acrylic polyurethane coating is prepared by mixing hydroxyl acrylic resin, a hydroxyl polyurethane plasticizer and a polyisocyanate curing agent. The acrylic polyurethane coating is mainly used for making the resin connecting material of an optical diffusion film, and the coating after the film formation has good light transmittance and light diffusion property and high scratch resistance, and has the advantages of prevention of falling off of resin micro beads in a diffusion layer. The acrylic polyurethane coating can also be used for making optical films such as brightening films and reflecting films, and the ratio of the three components can be adjusted according to the use and the substrate characteristics of different optical films so as to achieve the coating performances required by different purposes.

Owner:周建明

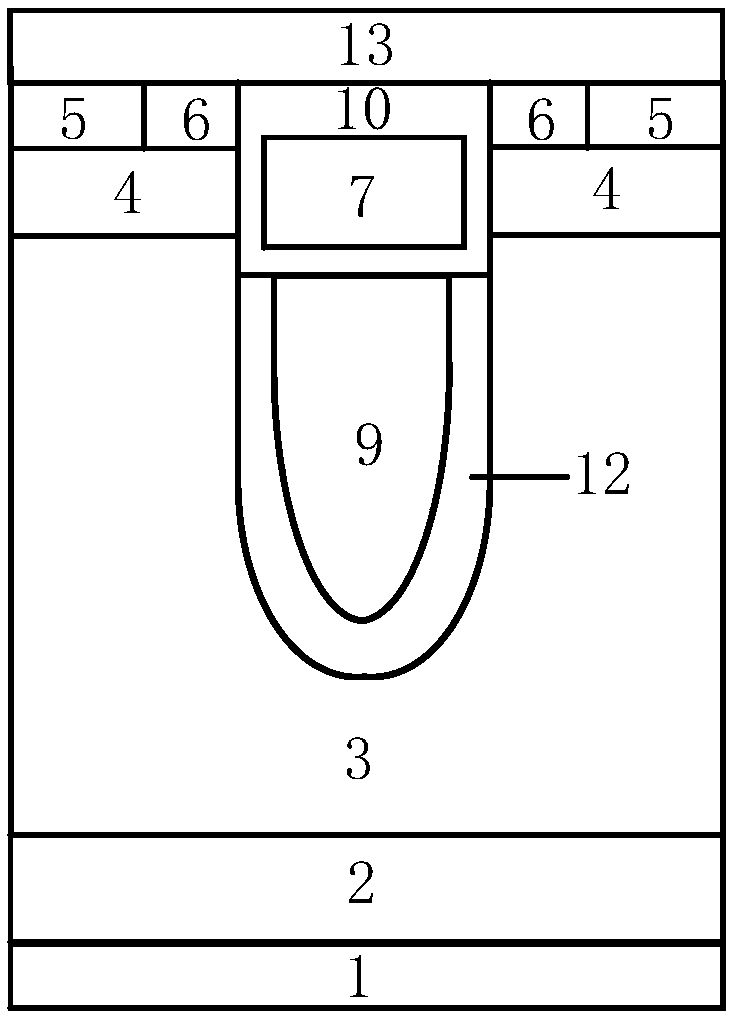

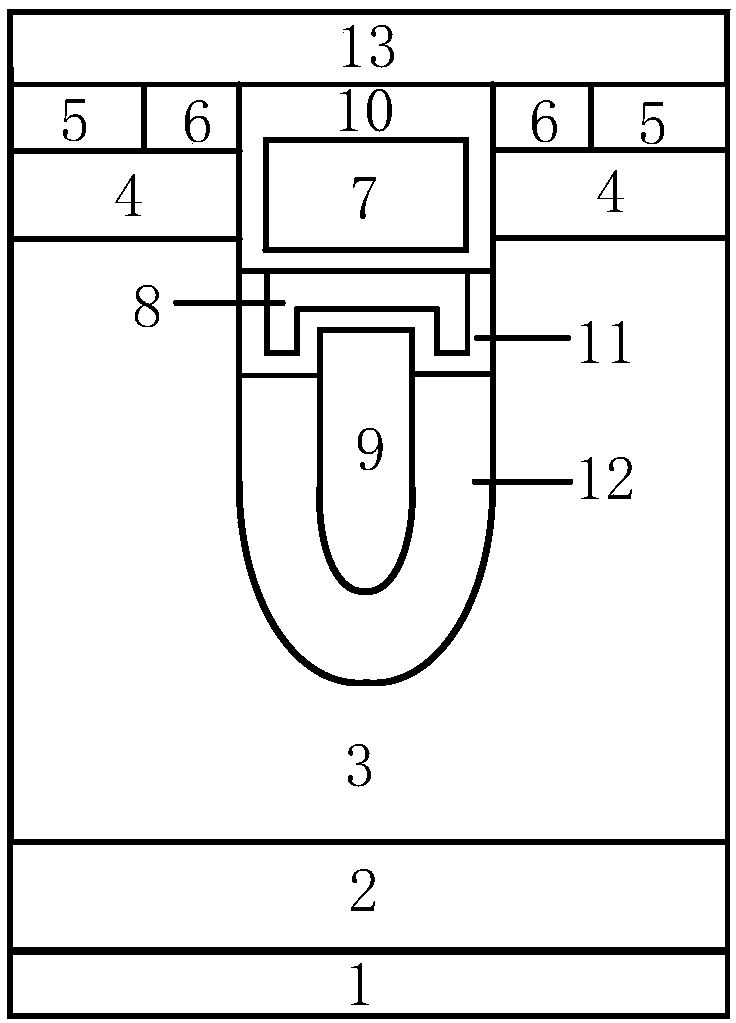

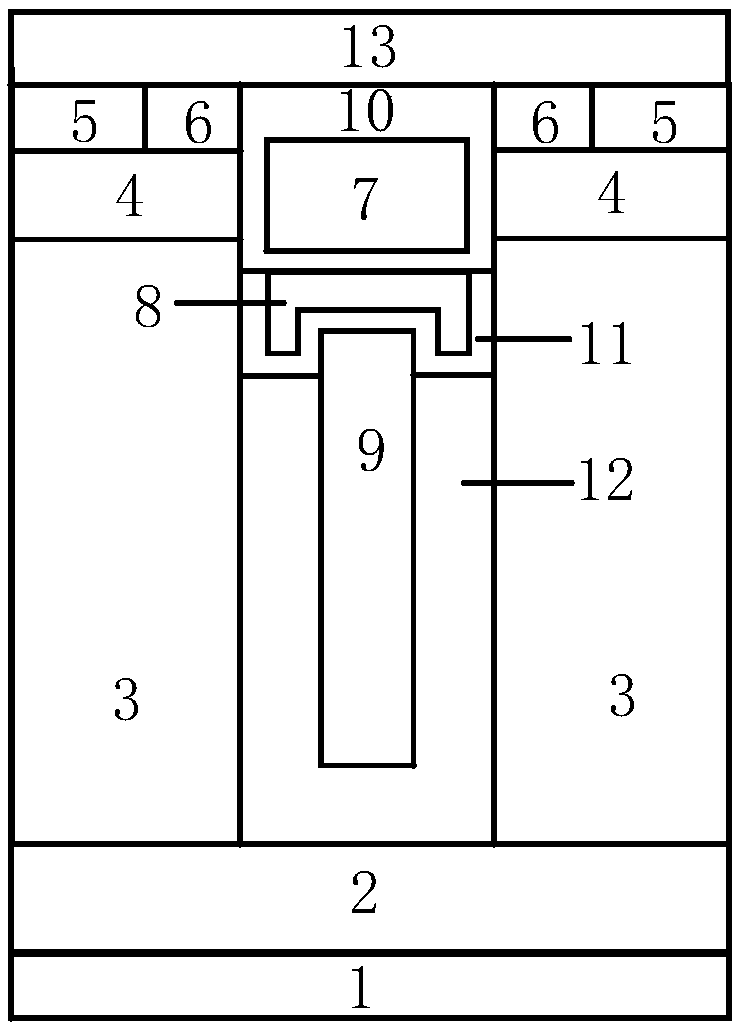

Shield grid DMOS device

ActiveCN109119468AAdjustable Gate-Source CapacitanceReduce switching lossesSemiconductor devicesCapacitanceDielectric layer

The present invention provides a shield grid DMOS device, belonging to the technical field of power semiconductors. An extra floating grid electrode is arranged between a control grid electrode and ashield grid electrode, dielectric layers are configured to mutually isolate the electrodes, the floating grid electrode with an adjustable position is introduced, the grid source capacitance of the device is reduced, the specific value of the grid source capacitance and the grid-drain capacitance is adjustable, and the combination of the floating grid electrode and the earthed shield grid electrode allows an electric field in a first conductive type semiconductor drift region to be more uniformly distributed. The shield grid DMOS device reduces the switching loss of the device, improves the device switching speed and voltage withstand level and improves the contradictory relation of the conduction resistance and the switching loss.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

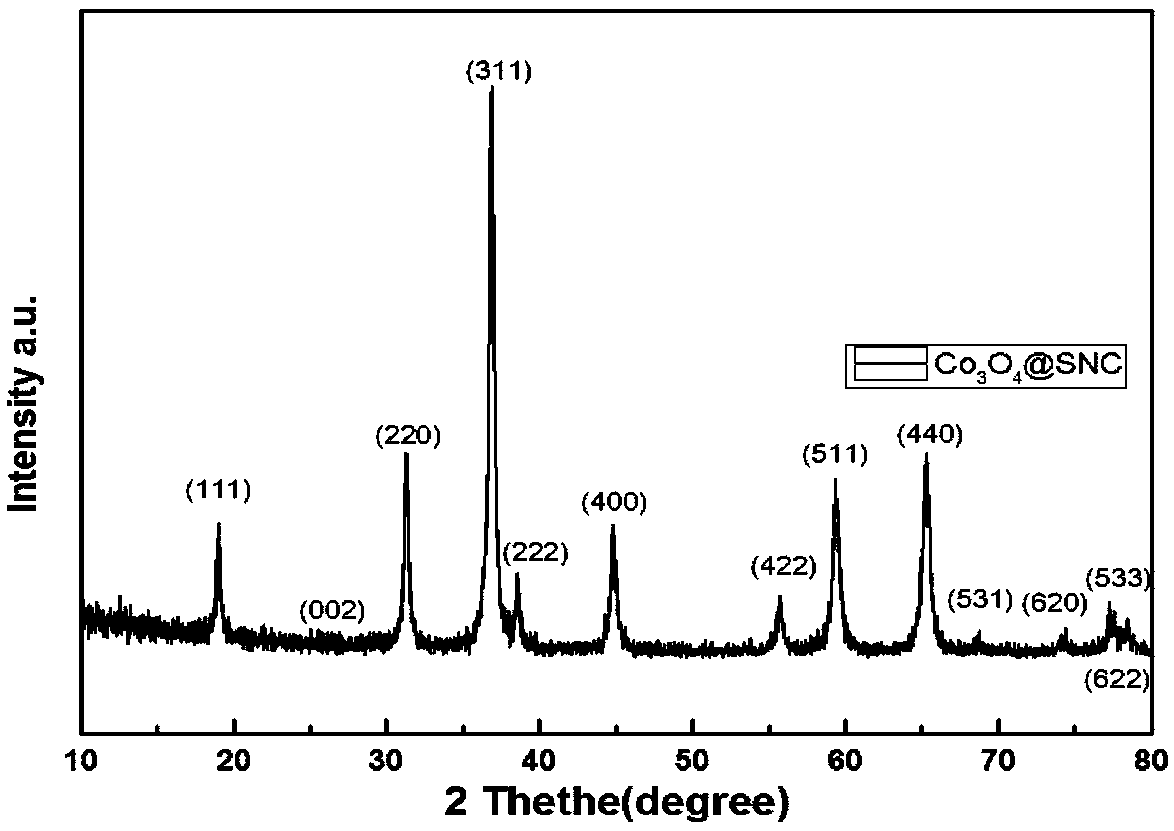

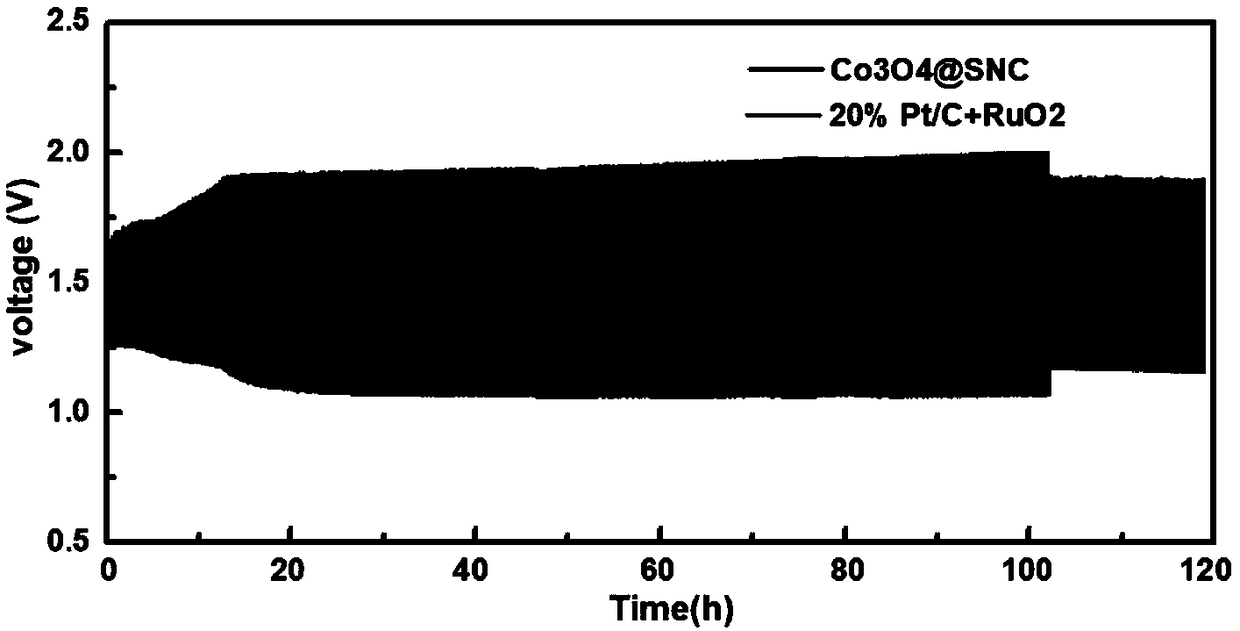

Carbon-doped transition metal oxide composite material and preparation method and application thereof

InactiveCN109148901AReduce processSimple processFuel and secondary cellsCell electrodesCarbon dopedIon

The invention provides a carbon-doped transition metal oxide composite material, a preparation method and an application thereof. The preparation method comprises the following steps: adding sodium alginate into deionized water, stirring to obtain transparent viscous liquid; Adding a sulfur and nitrogen source into a transition metal solution and stirring to obtain a homogeneous solution; Adding transparent viscous liquid into homogeneous solution dropwise, stirring, standing, and obtaining tubular gel hydrogel; Filtering, washing and freeze drying the tubular gel hydrogel to obtain a xerogel;Carbonizing the xerogel in an inert atmosphere to obtain pyrolytic clinker; The pyrolysis clinker is heat treated in air atmosphere, then washed and dried to obtain the doped carbon-based transitionmetal oxide composite. The method has the advantages of simple process, easy scalization, good catalytic activity and electrical conductivity, and can be used as a bifunctional catalyst for the positive electrode of the air electrode of the zinc-air battery.

Owner:CENT SOUTH UNIV

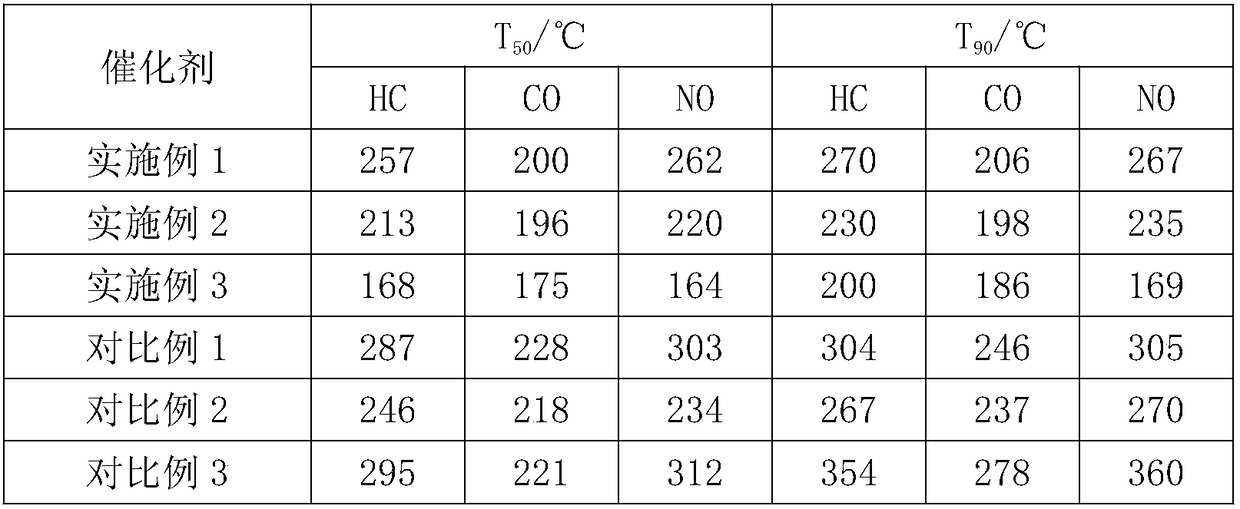

Three-way catalyst for treatment of tail gas of automobile and preparation method thereof

InactiveCN108273501AInhibition of agglomerationGood dispersionInternal combustion piston enginesDispersed particle separationPtru catalystCerium

The invention relates to a three-way catalyst for treatment of tail gas of an automobile. The three-way catalyst is prepared from the following components of an oxygen storage material, modified gamma-Al2O3 (aluminum oxide), a rare earth additive, an adhesive, and noble metal nitrate, wherein the modified gamma-Al2O3 is La (lanthanum)-modified gamma-Al2O3; the oxygen storage material is cerium-zirconium composite oxide; the weight ratio of oxygen storage material to modified gamma-Al2O3 is 2:3 to 3:2; the rare earth additive comprises one or multiple of nitrates of zirconium, praseodymium, neodymium and yttrium, and the amount of rare earth additive is equal to 1 to 5% of the total weight of the coating. The three-way catalyst has the advantages that in the coating preparation process, thenoble metal salt solution is firstly thinned, then added, and stirred, and stays overnight, so as to effectively inhibit the agglomeration of noble metals, improve the dispersion degree of noble metals, and improve the utilization rate of the noble metals; the low-temperature drying is adopted, so as to avoid the agglomeration of active components due to transfer of active components in the quickdrying process, and avoid the sintering in the roasting process; the usage amount of noble metals is reduced.

Owner:CHONGQING BRILLIANT TIGER CATALYTIC

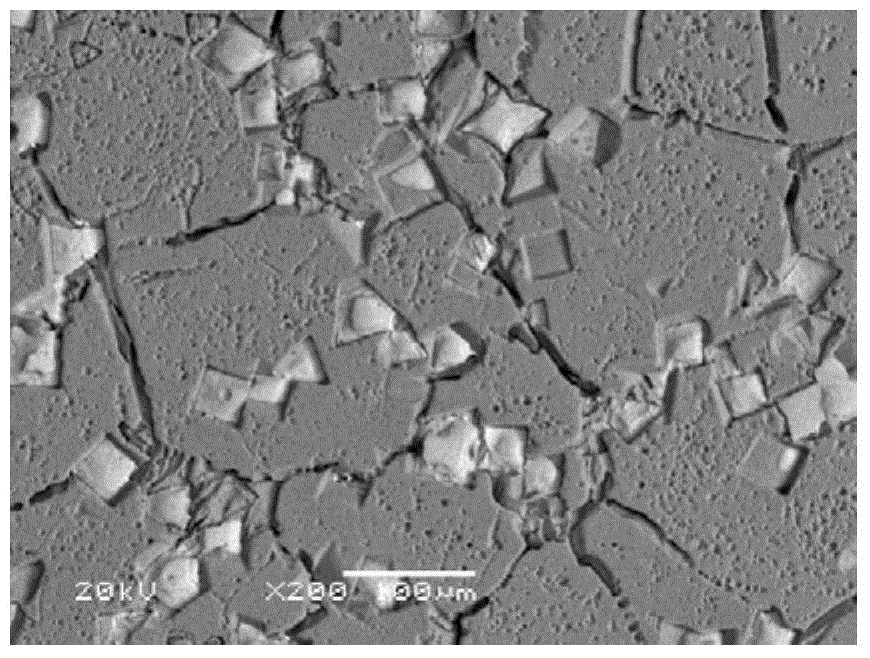

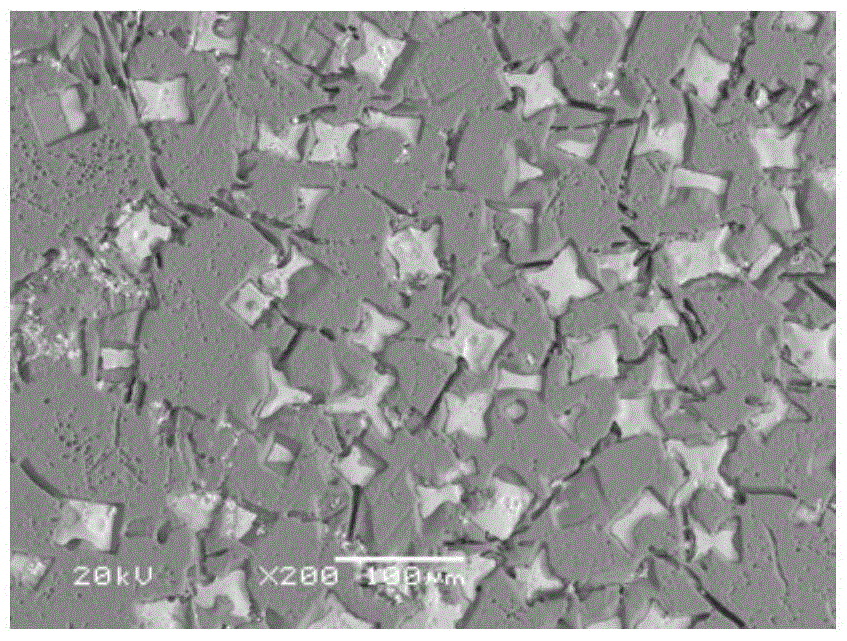

Stainless steel powder metallurgy material preparation method

A stainless steel powder metallurgy material preparation method is characterized by mixing 68.25-88.55wt% of Cr12 stainless steel powder, 10-30wt% of 440C stainless steel powder, 0.6-1.0wt% of graphite powder and 0.75-1.0wt% of stearate, pressurizing to ensure that the pressed green density is 5.8-6.2g / cm; sintering the material for 90-120min at 1260-1290 DEG C and at 5-20Pa, lowering the temperature to 950-1050 DEG C, then injecting nitrogen for cooling; reheating to 980-1060 DEG C and preserving the temperature for 30-45min and injecting nitrogen for cooling. The invention is a stainless steel powder metallurgy material preparation method with good formability and controllable sintering process which can meet the demands of the hardness and density. The method of the invention is applicable to preparing stainless steel products, beverage machinery and the like.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

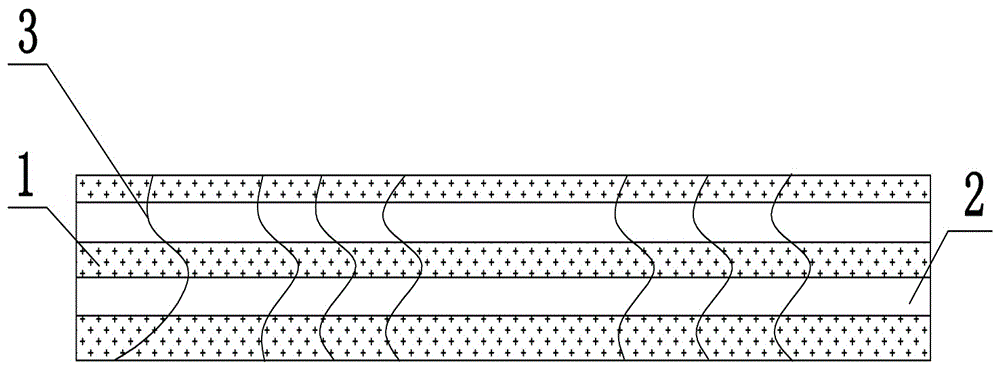

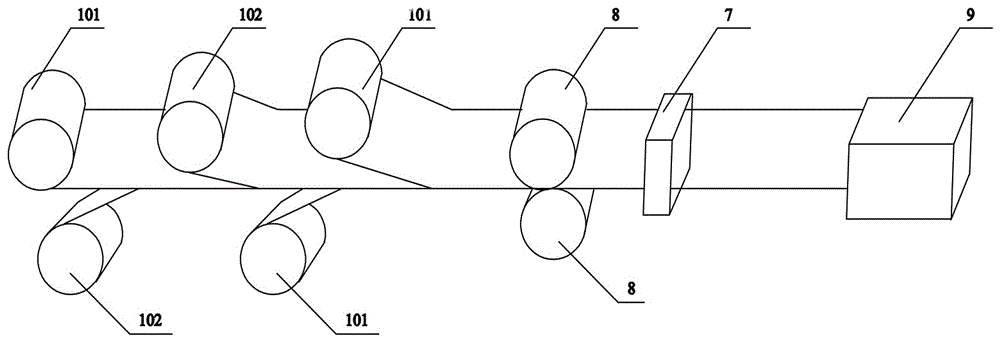

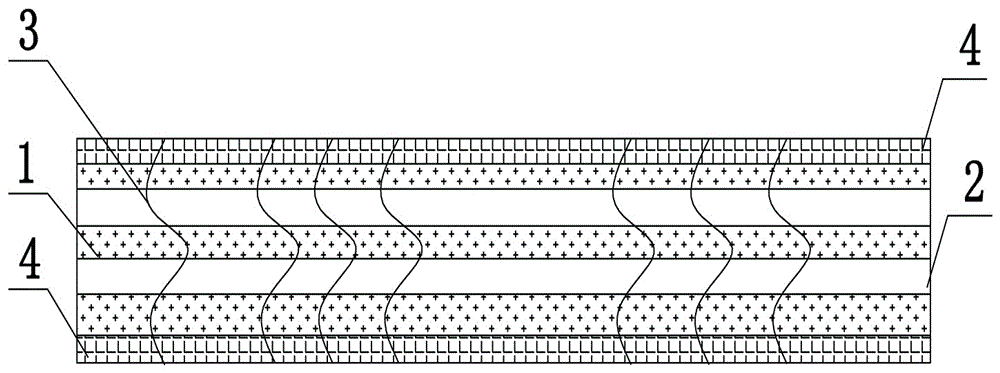

Thermoplastic continuous fiber composite material and preparation method thereof and production device

InactiveCN106113811AImprove breathabilityImprove liquid permeabilitySynthetic resin layered productsGlass/slag layered productsNonwoven fabricFibrous composites

The invention provides a preparation method of thermoplastic continuous fiber composite material. Paving parts; pre-pressing the paving parts to obtain preforms; subjecting the preforms to hot pressing and melting molding to obtain thermoplastic continuous fiber composite materials. The preparation method has simple process and is suitable for automatic production. The present invention also provides a thermoplastic continuous fiber composite material prepared by the method and a device for producing the composite material. The layers of the thermoplastic continuous fiber composite material are tightly bonded, and the provided device is simple in composition and easy to adjust. process steps.

Owner:ZHENGZHOU UNIV

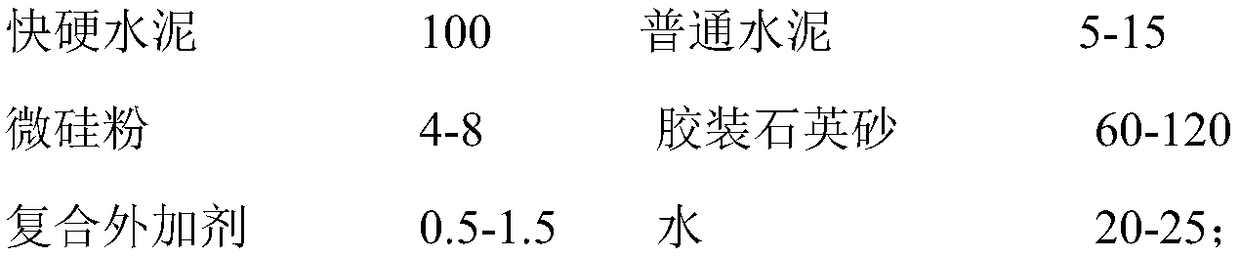

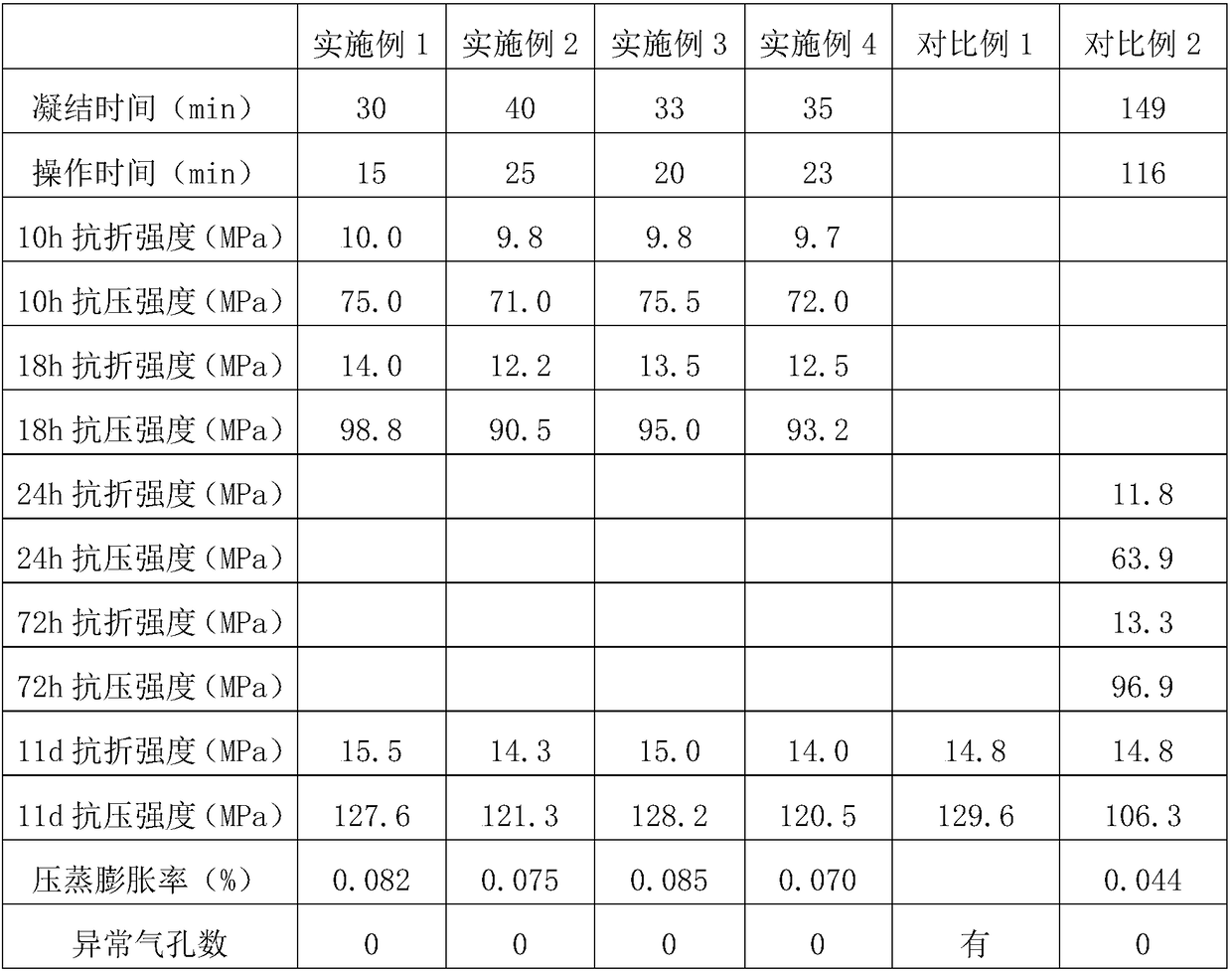

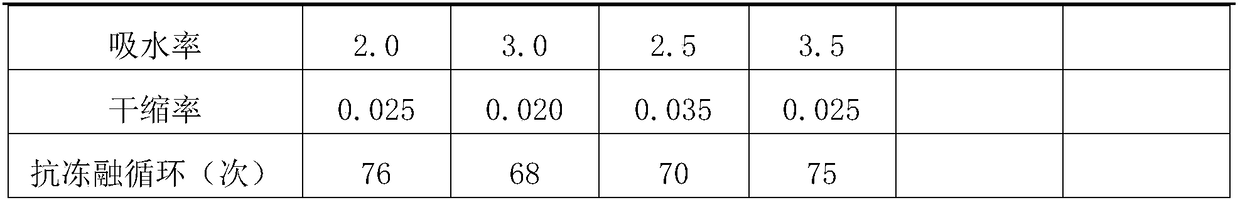

Cement adhesive with low energy consumption and super-early strength for binding of insulator and preparation method thereof

The invention relates to a cement adhesive with low energy consumption and super-early strength for binding of an insulator and a preparation method thereof. The cement adhesive is prepared from the following raw materials of quick-hardening cement, common cement, micro-silicon powder, binding quartz sand, a composite admixture and water, wherein the composite admixture consists of a retarder, a polycarboxylate superplasticizer, an early strength agent, a tackifier and a defoamer according to a ratio. The cement adhesive has the beneficial effects that (1) the production efficiency of the insulator is greatly improved by the compounding of the quick-hardening cement and the common cement; (2) the strength stability, anti-seepage property and durability are excellent; (3) by adopting the proper tackifier, the water sensitivity is decreased, the viscosity of the cement adhesive is adjusted, and the operability of the cement adhesive is obviously improved; (4) the binding time of the adhered insulator is greatly shortened, and the utilization rate of a curing tank is improved; (5) by adopting the three-step mixing method, the ratio of premixture to the quick-hardening cement is properly adjusted, so as to maintain the actual condensing time and operation time of the cement adhesive.

Owner:WUHAN UNIV OF TECH

Preparation method of carbon nano tube enhanced zinc-aluminum alloy-base composite material

The invention relates to a preparation method of a zinc-aluminum alloy-base composite material, in particular to a preparation method of a carbon nano tube enhanced zinc-aluminum alloy-base compositematerial. The aim is to solve the problems that according to an existing method, when carbon nano tubes are added into zinc-aluminum alloy melt, carbon nano tubes are not uniform in dispersion, and the mechanical properties of the prepared carbon nano tube enhanced zinc-aluminum alloy-base composite material are poor. The method includes the steps that 1, CNTs-Zn composite powder is prepared; 2, aCNTs-Zn intermediate material is prepared; 3, smelting is conducted, so that the carbon nano tube enhanced zinc-aluminum alloy-base composite material is obtained. The carbon nano tube enhanced zinc-aluminum alloy-base composite material can be obtained.

Owner:XIANGTAN UNIV +1

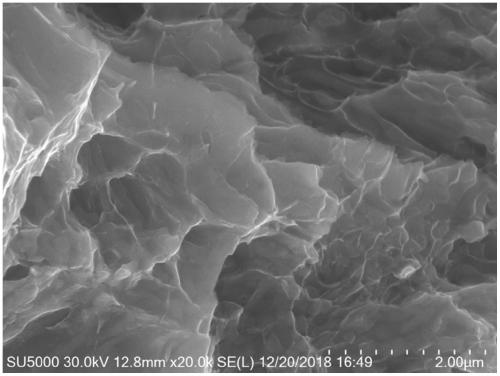

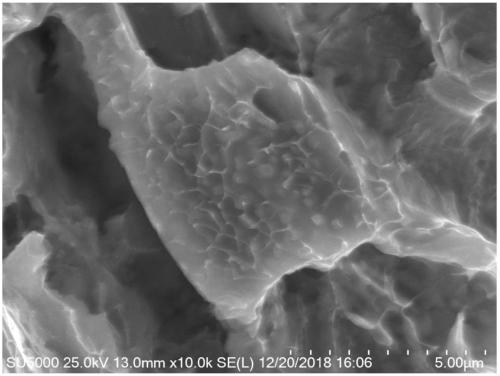

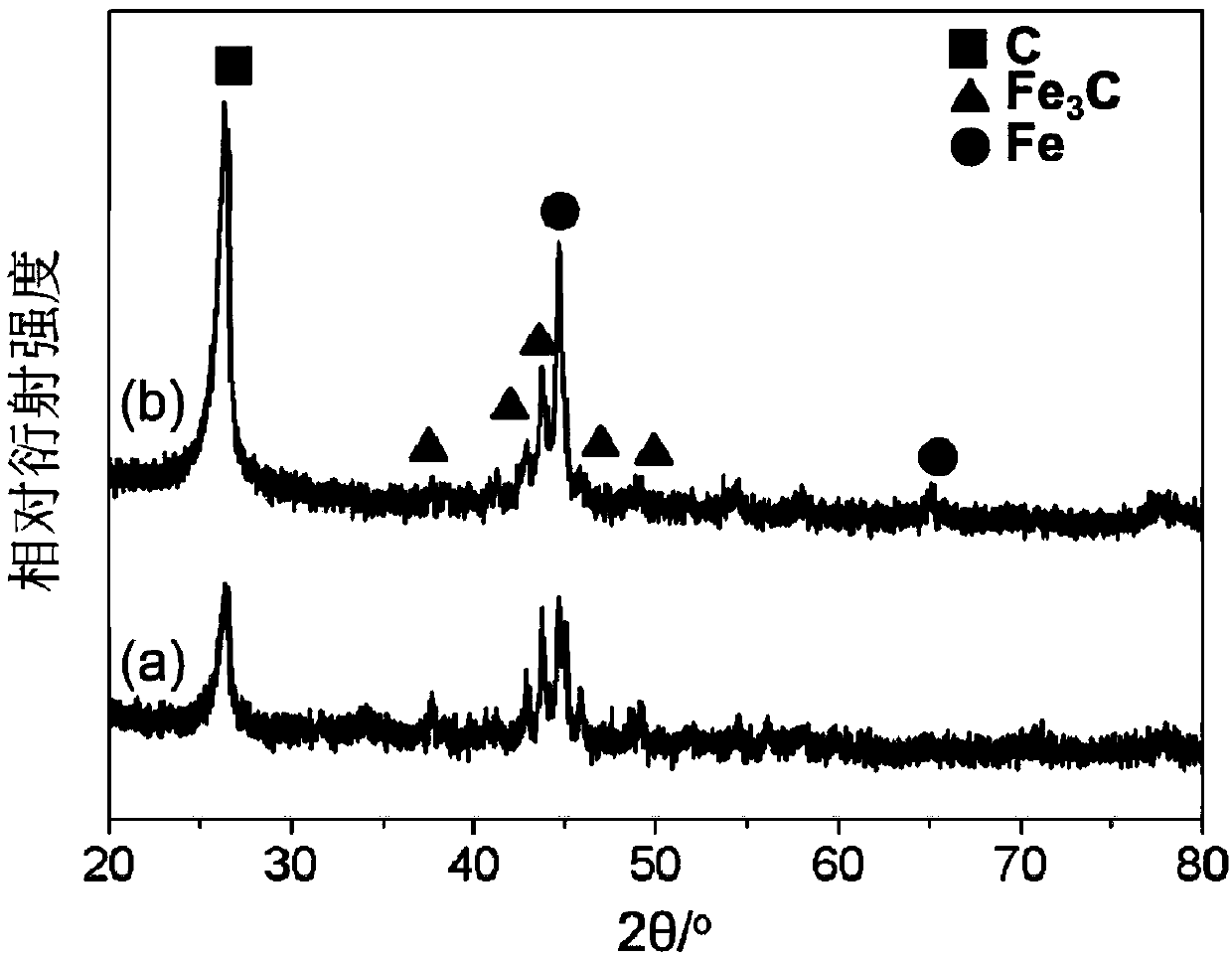

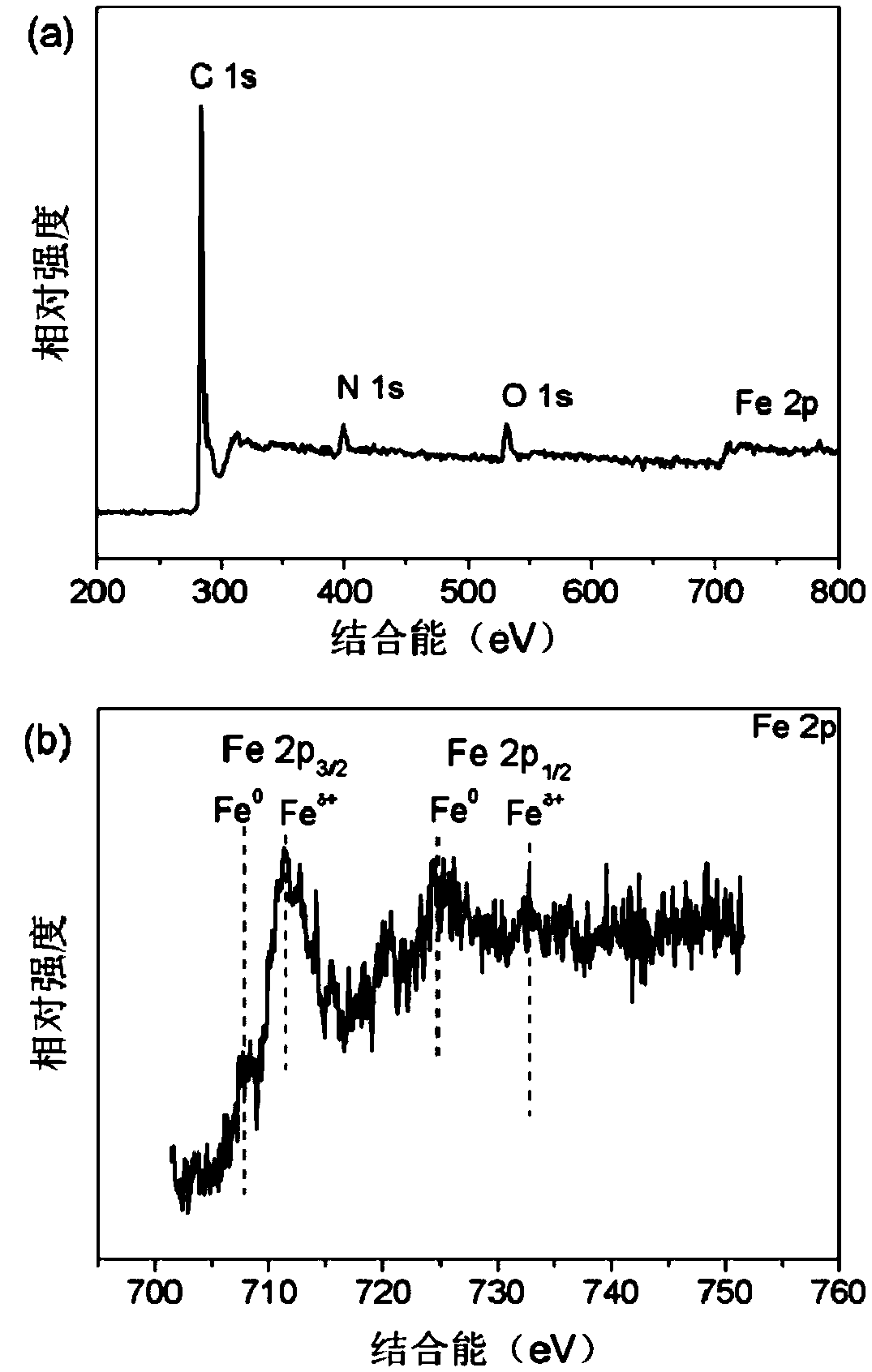

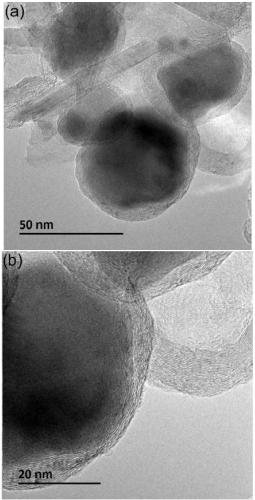

Nano-composite of carbon-coated iron and iron carbide, and preparation method for same

ActiveCN111185604AReduce dosageAvoid generatingMaterial nanotechnologyCarbon compoundsMeth-Cyanamide compound

The invention provides a preparation method for a nano-composite of carbon-coated iron and iron carbide. The method comprises the following steps: (S1) mixing one type or more than one types among citric acid coordinated iron or EDTA coordinated iron with one type or more than one types among cyanoguanidine and melamine to form a first precursor; (S2) treating the first precursor with first high-temperature pyrolysis under an inert atmosphere or a reducing atmosphere to obtain a primary composite material; (S3) mixing the primary composite material with one type or more than one types among cyanoguanidine, melamine and hexamine to form a second precursor; and (S4) treating the second precursor with secondary high-temperature pyrolysis under the inert atmosphere or the reducing atmosphere,wherein the temperature of the first high-temperature pyrolysis is higher than the temperature of the secondary high-temperature pyrolysis. In the method provided by the invention, through coordination effects of common and cheap organic acids and assistant effects of cyanamide compounds, a use dosage of low-efficiency cyanamide compounds is effectively reduced, and generation of CNT coated metalby-products is avoided. Through two low-temperature pyrolysis courses, defects of the composite are effectively repaired.

Owner:CHINA PETROLEUM & CHEM CORP +1

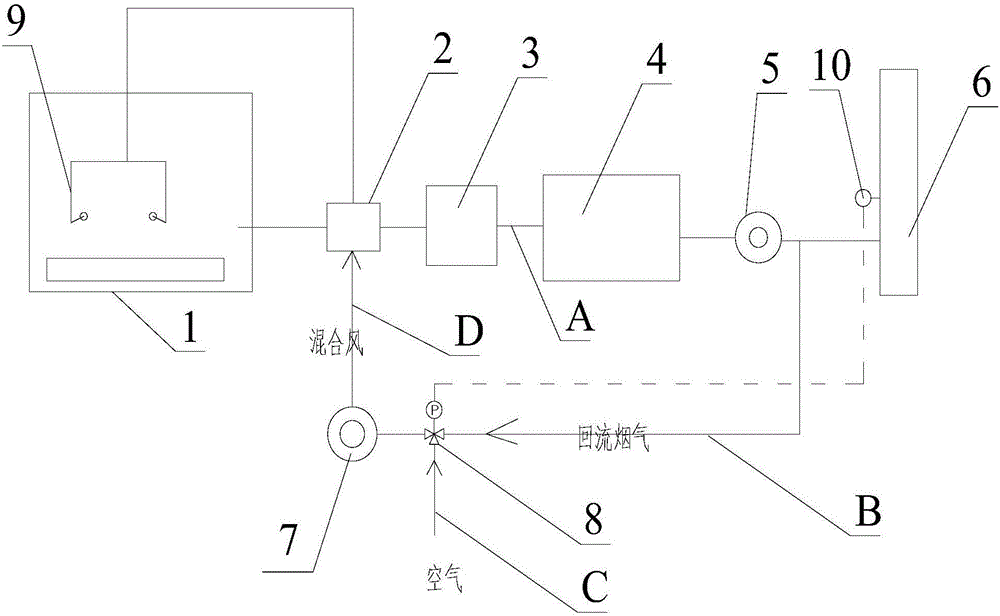

Biomass boiler system adjustable in air and backflow smoke ratio

ActiveCN106287666AAdjustable ratioImprove air flowSolid fuel combustionCombustion apparatusAir preheaterBaghouse

The invention discloses a biomass boiler system adjustable in air and backflow smoke ratio. The biomass boiler system comprises a boiler, an air preheater, a multi-pipe dust collector, a cloth bag dust collector, a draught fan, a chimney, a secondary draught fan and a three-way valve. The three-way valve specifically comprises two inlets and an outlet, specifically, the air inlet, the smoke inlet and the mixed gas outlet. The smoke inlet of the three-way valve is communicated with a smoke backflow pipeline. An air inlet pipeline is arranged at the air inlet of the three-way valve in a communication mode. A mixed gas pipeline is arranged at the mixed gas outlet of the three-way valve in a communication mode and communicated with the air side of the air preheater and a mixed air nozzle device in an inner cavity of the boiler in sequence. The biomass boiler system adjustable in air and backflow smoke ratio has the function that the air and backflow smoke ratio can be adjusted.

Owner:GUANGZHOU DEVOTION HOME ENVIRONMENT TECH CO LTD

Non-loaded type deep-hydrogenation catalyst and preparation method thereof

ActiveCN105363460AEvenly dispersedImprove high temperature thermal stabilityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsReactive siteActive component

The invention relates to a non-loaded type deep-hydrogenation catalyst and a preparation method thereof, and belongs to the field of catalyst preparation. The catalyst takes Ni and Mo as main active components and one or more of Zr, Zn, Al and Fe as an auxiliary active component; through BET-method determination, the catalyst has a mesoporous structure, and has the mesoporous diameter of 5.0-7.0 nm and the specific surface area of 100-300 m<2> / g. With combination of characteristics of simple operation of a precipitation method and catalyst thermal stability improvement of a hydrothermal synthesis method, the defects of long period, low metal utilization rate and high cost are overcome, the obtained catalyst not only has more metal active sites, but also has the hydrothermal stability improved. In the preparation process of the catalyst, no other binders are used, the preparation process is simplified, and the cost of the catalyst is reduced.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

Method for preparing column shaped horniness phase composite wear-resistant jaw plate

InactiveCN101412101AImprove wear resistanceHigh tensile strengthGrain treatmentsCompound aWear resistant

The invention discloses a method for preparing a composite crushing plate with a columnar hard phase. A gear rack of the composite crushing plate with the columnar hard phase prepared by the method is formed by compounding a high hardness columnar hard phase and a high tenacity base metal. The method comprises the following steps: weaving alloy powder core materials into an alloy powder core material framework according to the shape of the gear rack on the crushing plate; fixing the framework on the crushing plate through binding or welding; through a casting method, performing in situ reaction on the alloy powder core materials to generate the columnar hard phase by using the high temperature of melted base molten metal; and performing the metallurgical combination of the hard phase and a base metal interface to form a high wear resistant high tenacity composite material on the gear rack of the crushing plate. The composite crushing plate prepared by the method has the advantages of high wear resistance, high tenacity, high tensile strength, high compression strength and the like. The method has the characteristics of small equipment input, low cost, simple operation and the like, and can be widely applied to various jaw type crushers.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

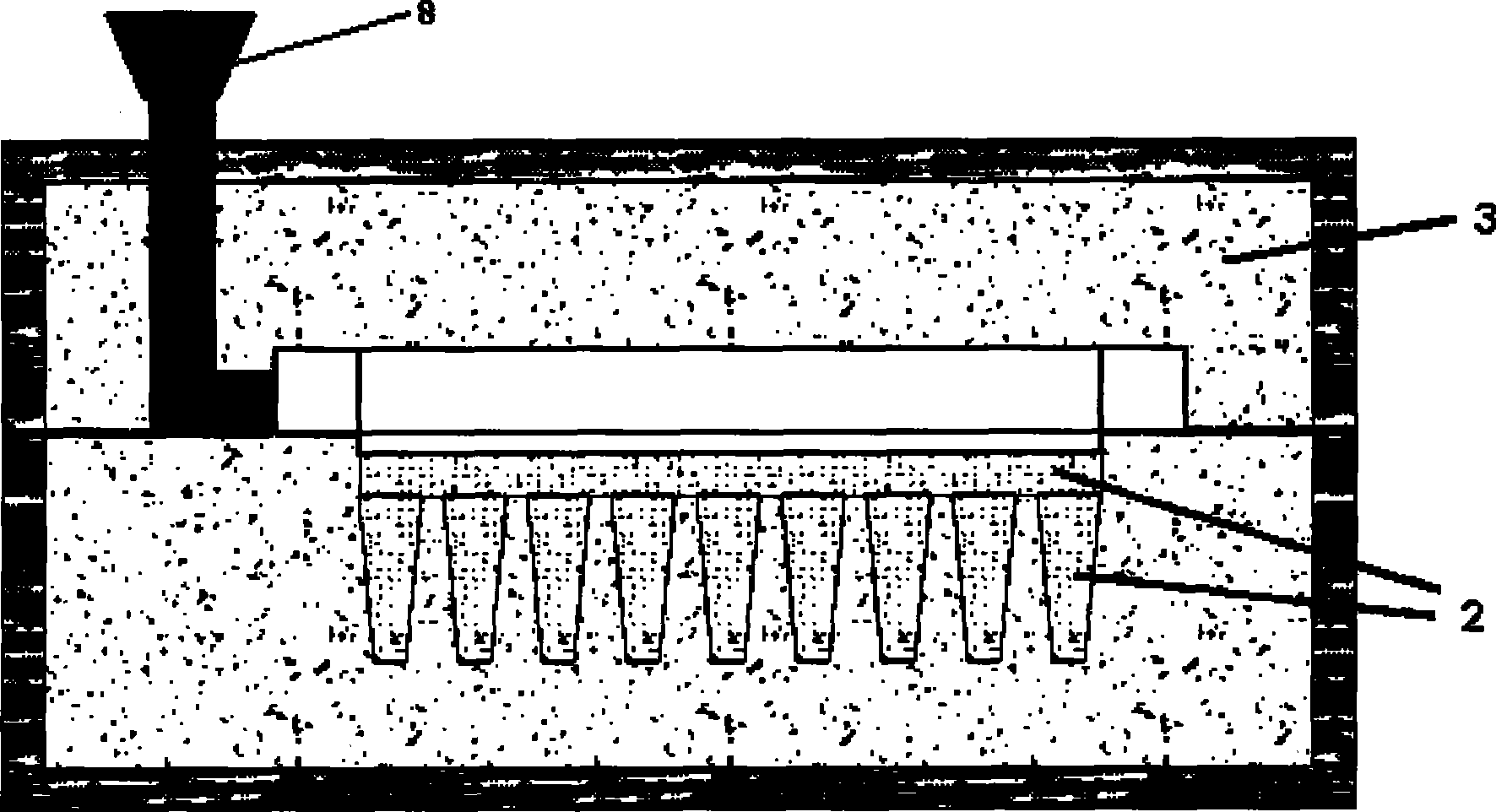

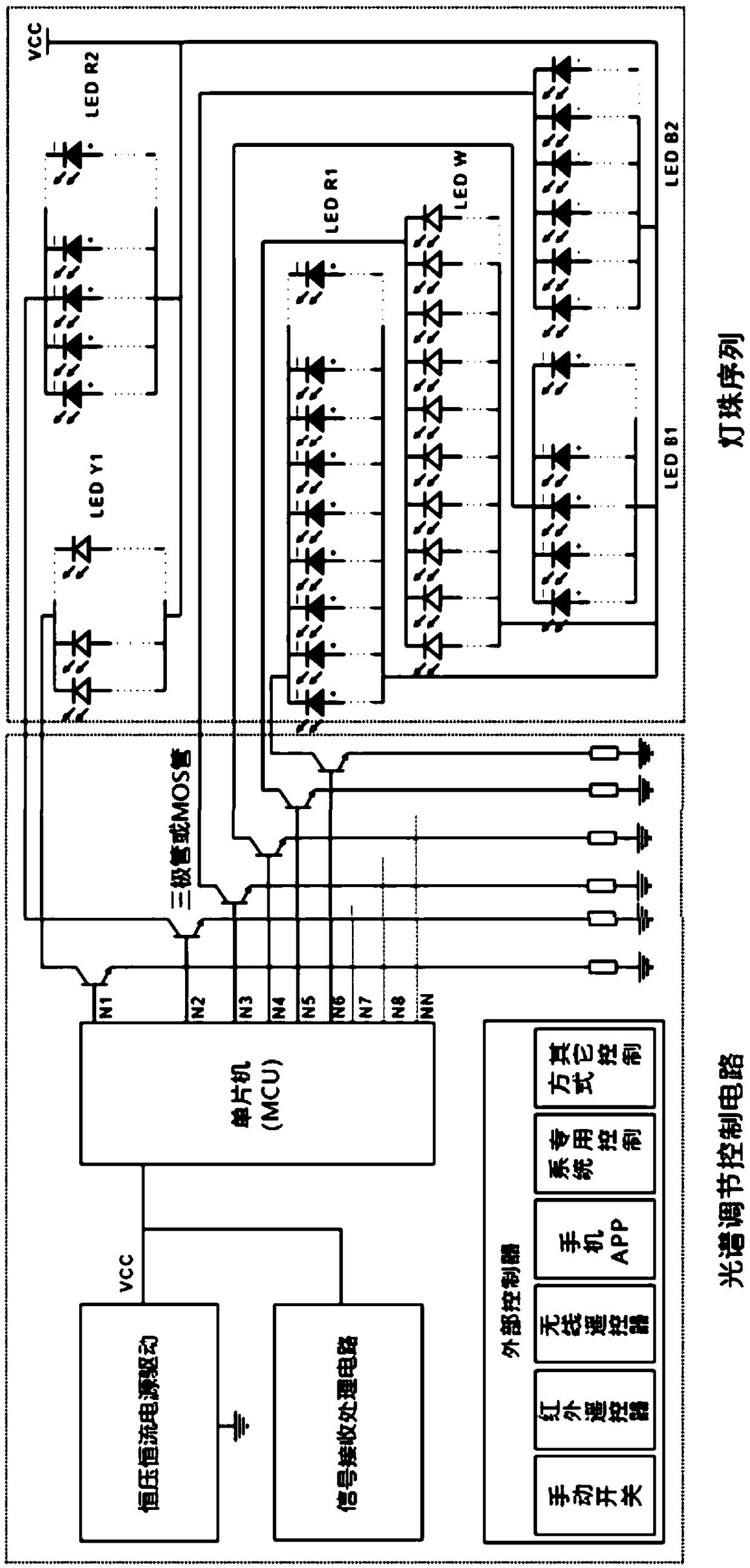

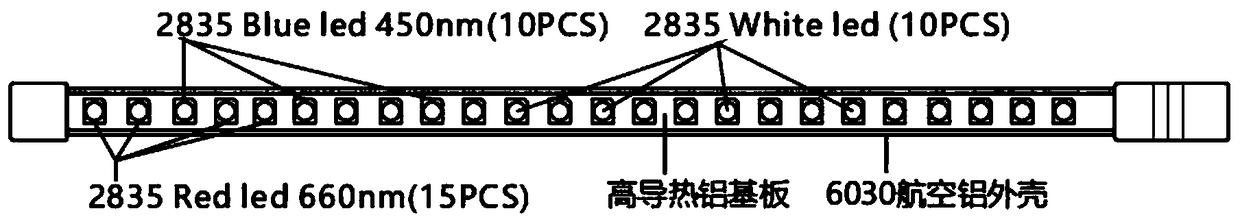

Plant growth light supplementing lamp

PendingCN109210417AAdjustable ratioMeet Spectral NeedsLight source combinationsElectrical apparatusUltraviolet lightsLighting spectrum

The embodiment of the invention provides a plant growth light supplementing lamp, and belongs to the technical field of plant growth and light supplementing. According to the invention, the problems of non-adjustable spectral proportion, low using efficiency, high cost, single function and the like for existing plant growth light supplementing lamps can be solved. The plant growth light supplementing lamp comprises a spectrum adjustment control circuit and an LED lamp bead sequence. The LED lamp bead sequence comprises a blue light source, a red light source, a white light source, an infraredlight source and an ultraviolet light source. The spectrum adjustment control circuit comprises at least two control branches. The LED lamp bead sequence is driven by each of the two control branchesto emit light in the form of a lamp bead combination formed by lamp beads arranged according to a certain proportion and set in different colors. The plant growth light supplementing lamp is low in cost, adjustable in spectral proportion and applicable to various plant growth requirements. The plant growth light supplementing lamp is mainly used for providing a required light spectrum for plants in the plant growth process, and promoting photosynthesis to assist the plant growth.

Owner:深圳长弓半导体技术有限公司

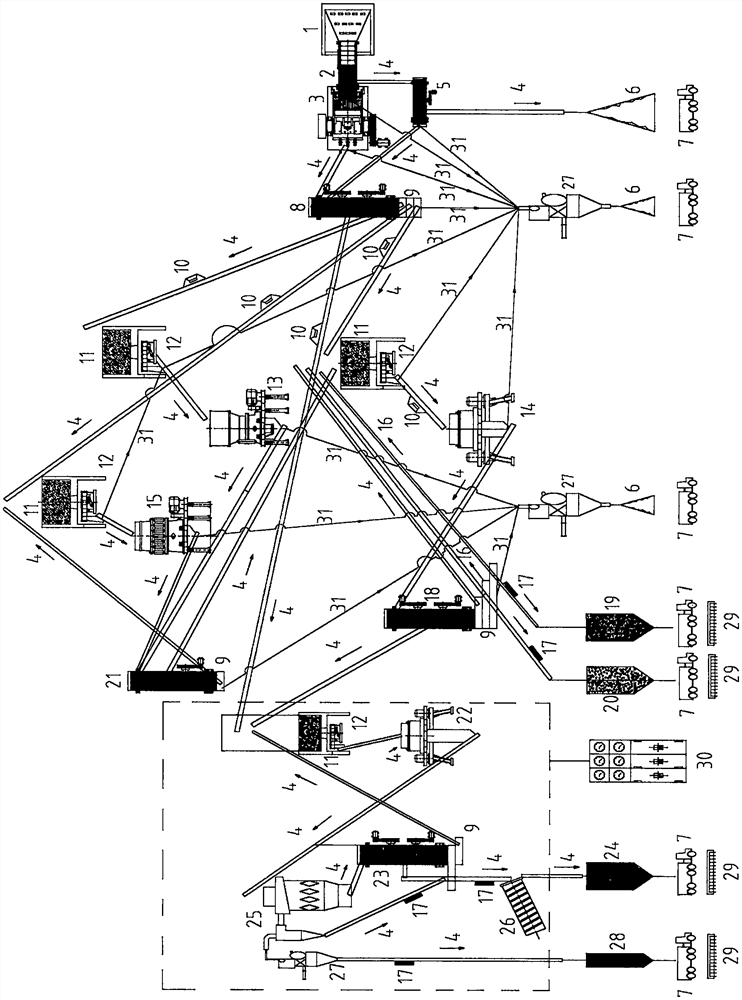

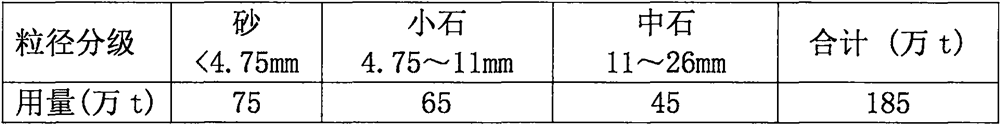

High-quality granite machine-made sandstone aggregate production line and technological process thereof

PendingCN112439530AGuaranteed grain effectAdjustable ratioSievingScreeningControl systemProcess engineering

The invention belongs to the field of machine-made sandstone equipment manufacturing and provides a high-quality granite machine-made sandstone aggregate production line. The production line adopts acrushing and screening process of jaw crusher coarse crushing, desilting and screening, pre-screening, cone crusher secondary intermediate crushing, vertical shaft impact crusher shaping and coarse aggregate finished product screening at the front end, and adopts a floor type sand making process at the rear end. According to the production line, technical means such as a computer network, wirelesscommunication, spatial positioning and geographic information are comprehensively utilized, monitoring and control information of operation of production line equipment compositions is integrated into a set of intelligent monitoring and control system, dynamic management and control of the sandstone aggregate production line are achieved, and controllability and flexibility of the whole production process are achieved. By adopting the production line, firstly, the high quality of the finished aggregate can be ensured; secondly, green and environment-friendly production process can be realized; and thirdly, the intelligent process control can be realized, and the controllability and the flexibility of the whole production process are ensured.

Owner:青岛方特远矿山机械有限公司

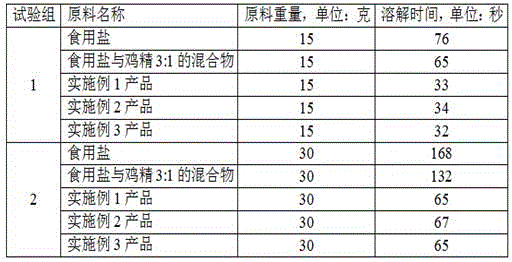

Instant compound seasoning suitable for preparing mixed rice noodles

The invention discloses an instant compound seasoning suitable for preparing mixed rice noodles. The instant compound seasoning is prepared from the following components in parts by weight: 80-100 parts of edible salt, 15-30 parts of chicken essence, 1-2 parts of starch, 1-3 parts of maltodextrin, 0.5-1 part of disodium 5'-ribonucleotide, 1-10 parts of ground pepper, 1-30 parts of chilli powder and 1-5 parts of dried ginger powder. Since the instant compound seasoning disclosed by the invention contains insoluble ground pepper, chilli powder and dried ginger powder, the obtained particles are looser with more pores and are dissolved in water faster; and with the salty, fresh, hemp, spicy, aromatic and other tastes, the workload of preparing mixed rice noodles is reduced, and the preparation efficiency of mixed rice noodles is improved.

Owner:JIANGXI XIANGCHU IND CO LTD

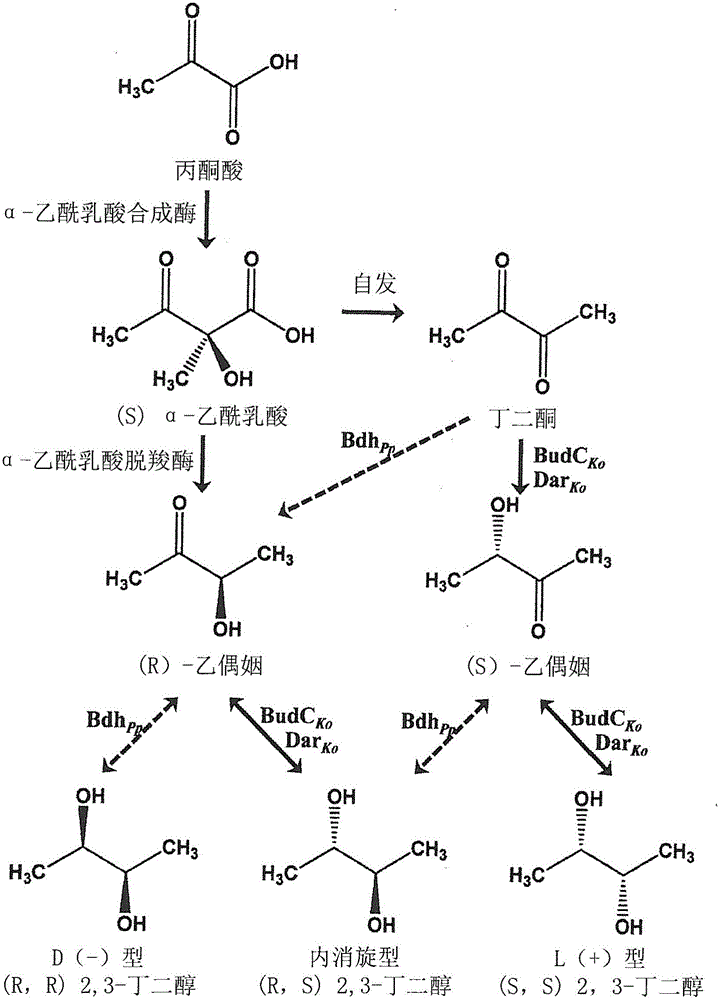

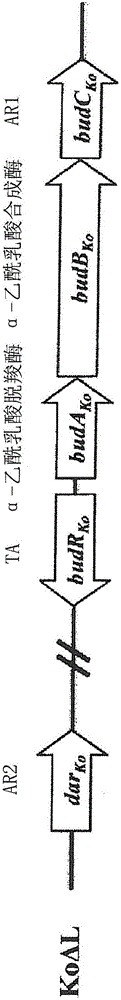

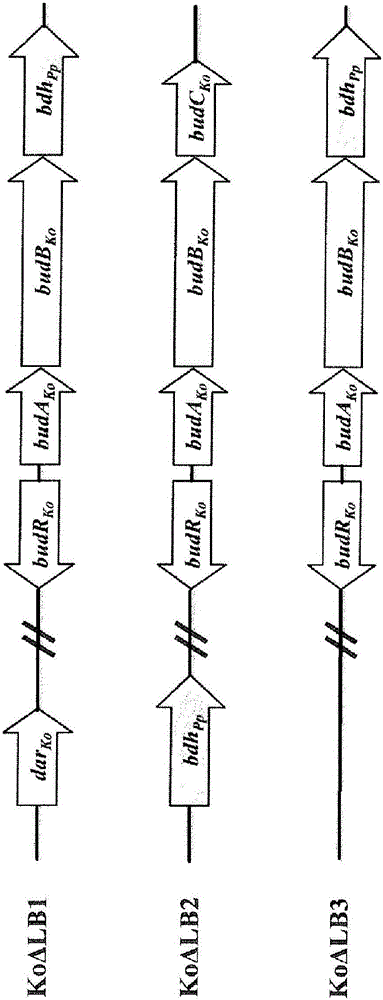

Recombinant microorganism having increased d(-) 2,3-butanediol productivity, and method for producing d(-) 2,3-butanediol by using same

Owner:GS CALTEX CORP

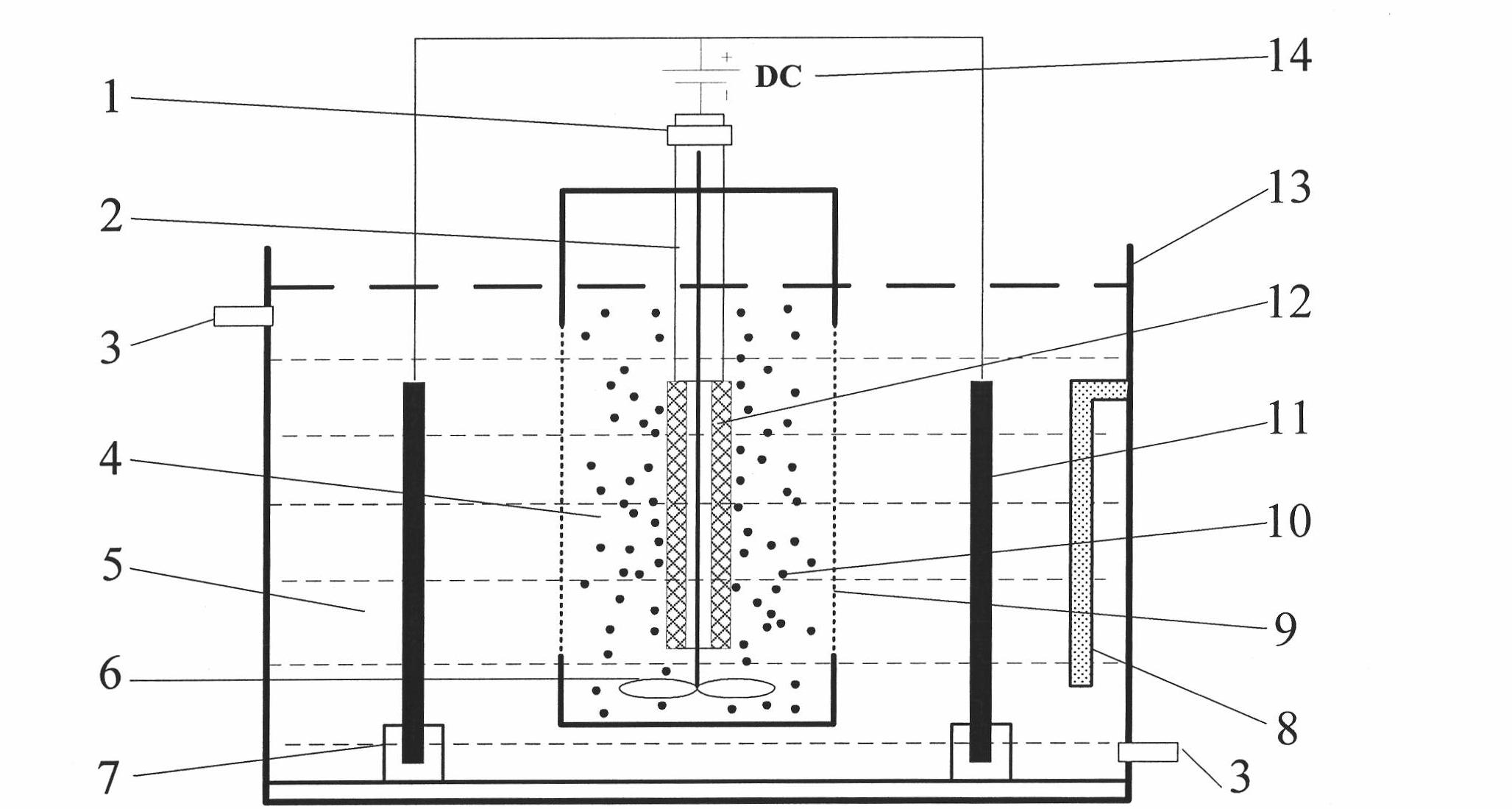

Method and device for plating cladding magnetic material on microorganism surface

The invention discloses a method and device for plating cladding magnetic material on a microorganism surface. The method comprises the following steps: (1) template pretreatment; (2) template conduction treatment; (3) cladding of magnetic material; (4) dehydration treatment; and (5) vacuum drying. The device comprises a plating tank, a diaphragm, a vibrator, a stirrer, an electrode, a circulation pump and the like. The plating tank is divided into a cathode tank and an anode tank by a round diaphragm; a multi-layer cylindrical copper grid electrode is arranged in the cathode tank, and the top of a fixture of the copper grid electrode is connected with the vibrator; a mechanical stirrer is arranged at the centre of the copper grid electrode; a bracket is arranged at the bottom of the anode tank, and a six-hole cylindrical graphite electrode is fixed on the bracket; and the circulation pump is connected with the two sides of the anode tank through two pipelines with valves. Through the invention, the materials are easily available, the process is stable, microorganism coalescence in the plating process can be effectively avoided, and the original body characteristics of the microorganism are maintained.

Owner:BEIHANG UNIV

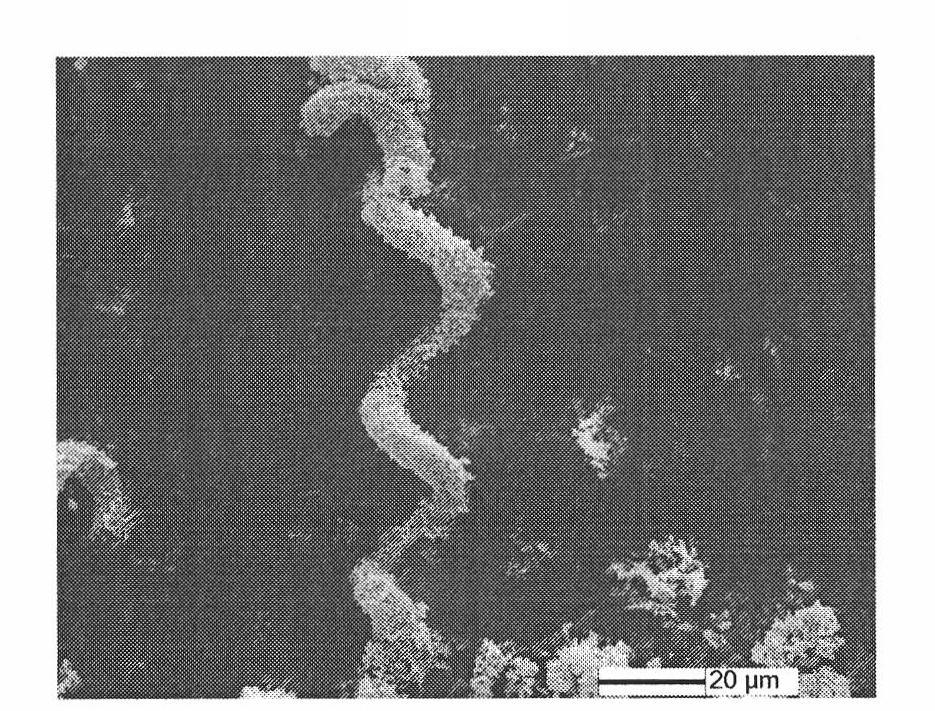

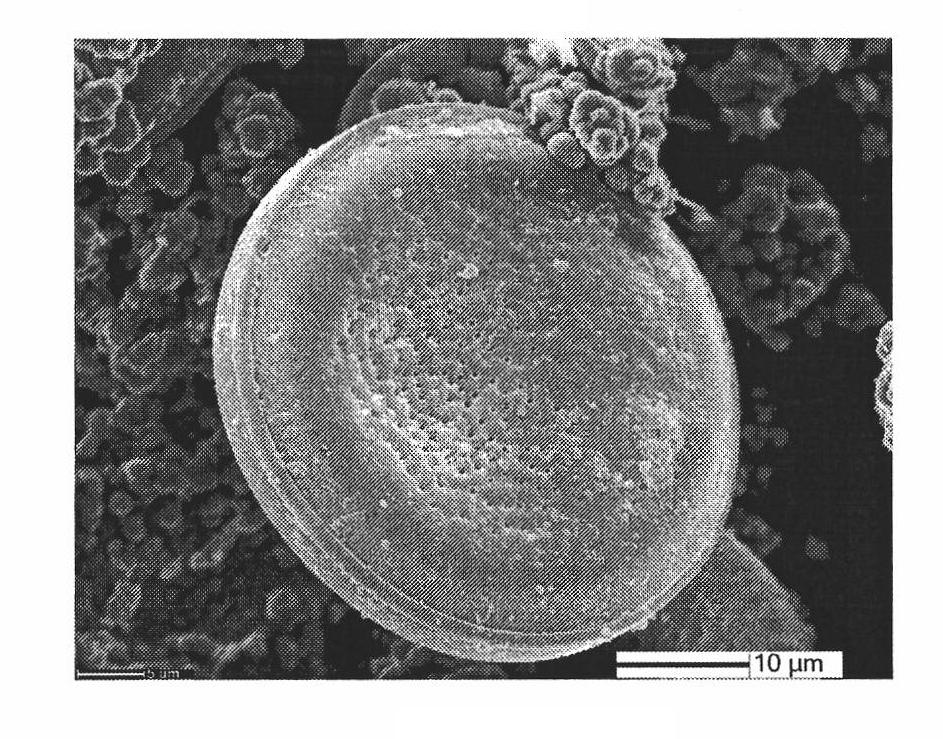

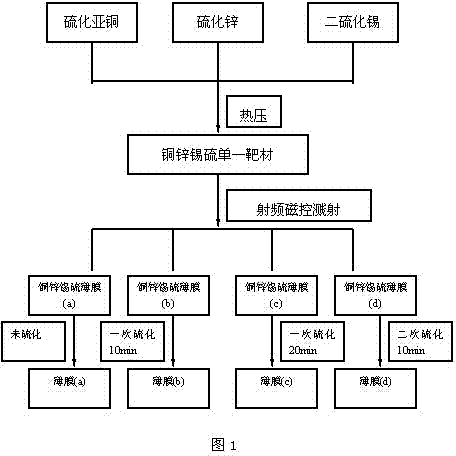

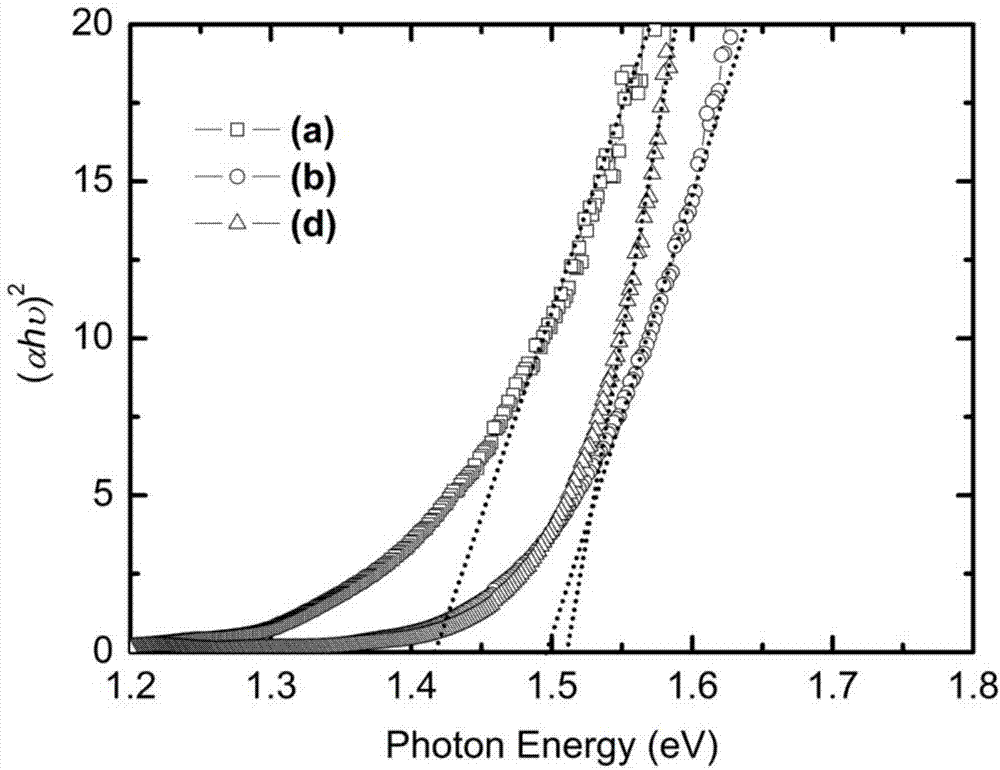

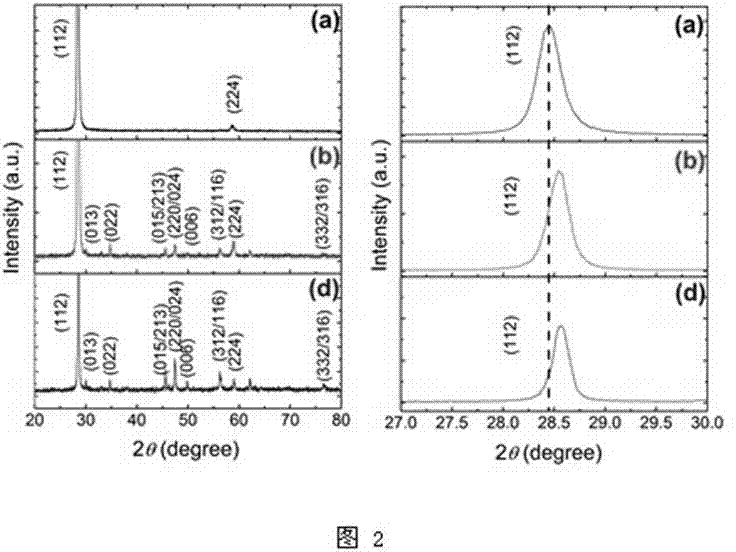

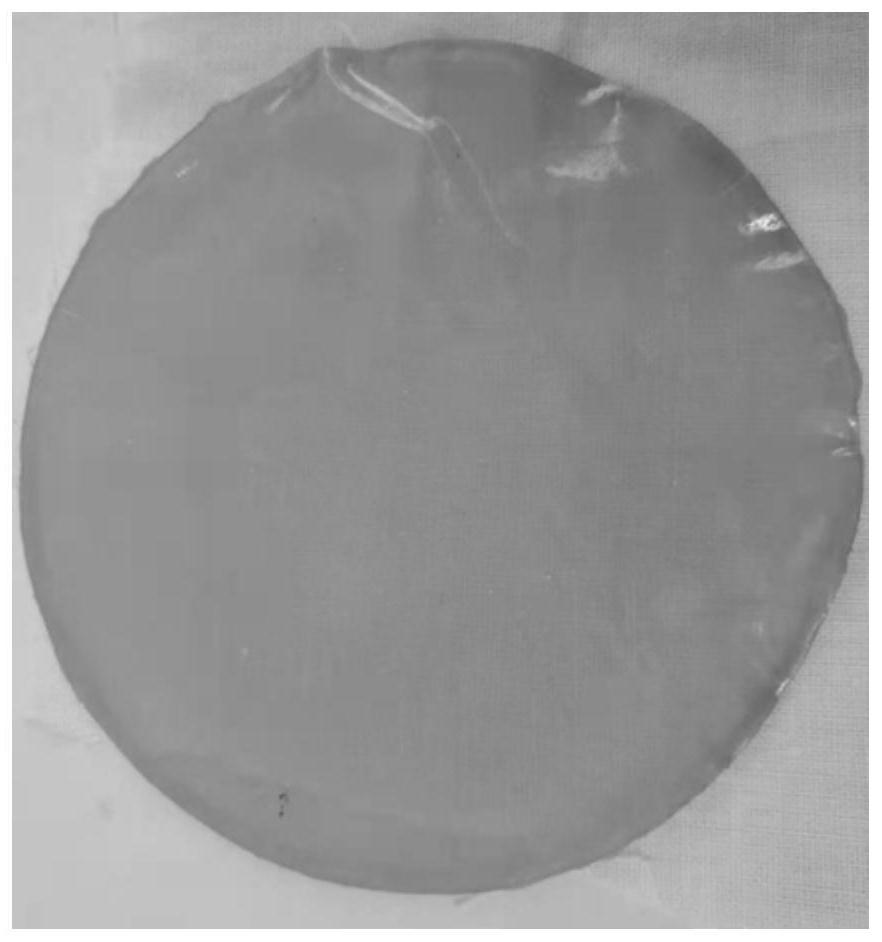

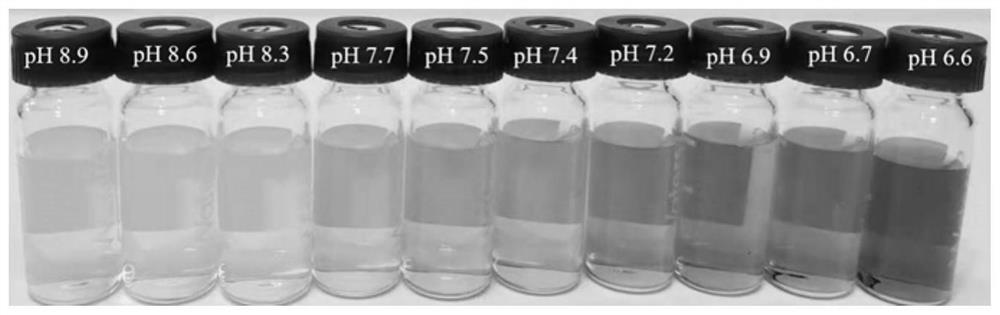

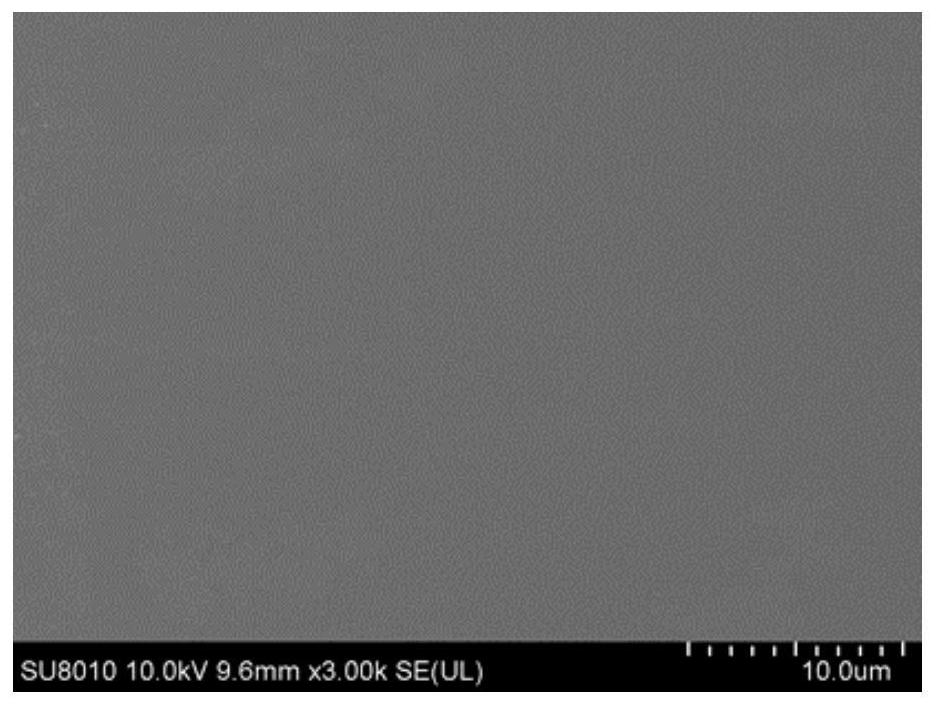

Preparation method for adjusting element ratio of Cu2ZnSnS4 film through two times of sulfuration

InactiveCN104282804AAdjustable ratioEase of Conversion Efficiency EffectsFinal product manufacturePhotovoltaic energy generationSputteringSulfur

The invention relates to a preparation method for adjusting the chemical ratio of a Cu2ZnSnS4 film through two times of sulfuration heat processing. The preparation method is characterized in that magnetron sputtering is carried out on a Cu2ZnSnS4 prefabricated film through the single Cu2ZnSnS4 target, two times of sulfuration heat processing is carried out on the prefabricated film, and the high-quality Cu2ZnSnS4 film poor in copper and rich in zinc is obtained. The corresponding band gap is changed from 1.42eV to 1.52eV. The preparation method for adjusting the chemical ratio of the Cu2ZnSnS4 film through two times of sulfuration heat processing is simple in process, low in cost, convenient to operate, high in repeatability and favorable for industrialization development of stacked solar cells with Cu2ZnSnS4 absorption layers.

Owner:JILIN INST OF CHEM TECH

Carbon fiber cloth and paper pulp papermaking composite cone

InactiveCN109218932AAdjustable ratioImprove firmnessElectrical transducersLoudspeakersPulp and paper industryLoudspeaker

The invention relates to a paper cone in a loudspeaker. A carbon fiber cloth and paper pulp direct papermaking composite cone is formed by impregnating a carbon fiber woven fabric with resin; then placing the carbon fiber woven fabric on a papermaking mold, and drying the carbon fiber woven fabric together with the papermaking wet paper pulp to form a composite paper cone. Further, the weight ratio of the carbon fiber woven fabric to the paper pulp is 1:1 to 1:1.5. The invention relates to a composite cone composed of carbon fibers and paper pulp. The paper pulp penetrates into the carbon fiber cloth and interweaves with the carbon fiber cloth. Thus, glue bonding is not required and good firmness is achieved. The paper cone has both the rigidity of the carbon fibers and the damping of paper fibers. The paper pulp ratio can be adjusted to achieve an effect with less distortion and realistic reproduction of various sounds.

Owner:XINGSHENG PRECISION PARTS HUIZHOU

Preparation method of hydrophobic film and application of hydrophobic film in visual detection of freshness of fruit and vegetable

ActiveCN113527728AIndicativeImprove hydrophobicityMaterial analysis by observing effect on chemical indicatorCellulosePolyvinyl alcohol

The invention discloses a preparation method of a hydrophobic film and application of the hydrophobic film in visual detection of freshness of fruit and vegetable. The preparation method comprises the following steps: (1) dissolving polyvinyl alcohol in water, conducting stirring at 60-90 DEG C for 1-2 hours, performing cooling, adding an aqueous polyethyleneimine solution, and continuing stirring for 1-2 hours to prepare PVA hydrogel mixed with PEI; (2) preparing an ethanol solution of ethyl cellulose; (3) slowly adding the ethanol solution of the ethyl cellulose obtained in the step (2) into the PVA hydrogel mixed with the PEI obtained in the step (1) in proportion, adding a plasticizer glycerol at the same time, and conducting stirring at 40-70 DEG C for 2-4 hours to obtain mixed hydrogel; (4) adding methyl red and methyl red sodium salt into the mixed hydrogel, and carrying out stirring for 0.5-1 hour to obtain a film forming solution; and (5) pouring the film forming liquid into a mold for film casting, and carrying out standing and drying to obtain the hydrophobic film. The invention provides the application of the hydrophobic film in visual detection of the freshness of fruit and vegetable, and the hydrophobic film can visually and accurately indicate the freshness of respiratory climacteric fruit and vegetable, and has good hydrophobicity and mechanical properties at the same time.

Owner:ZHEJIANG UNIV OF TECH

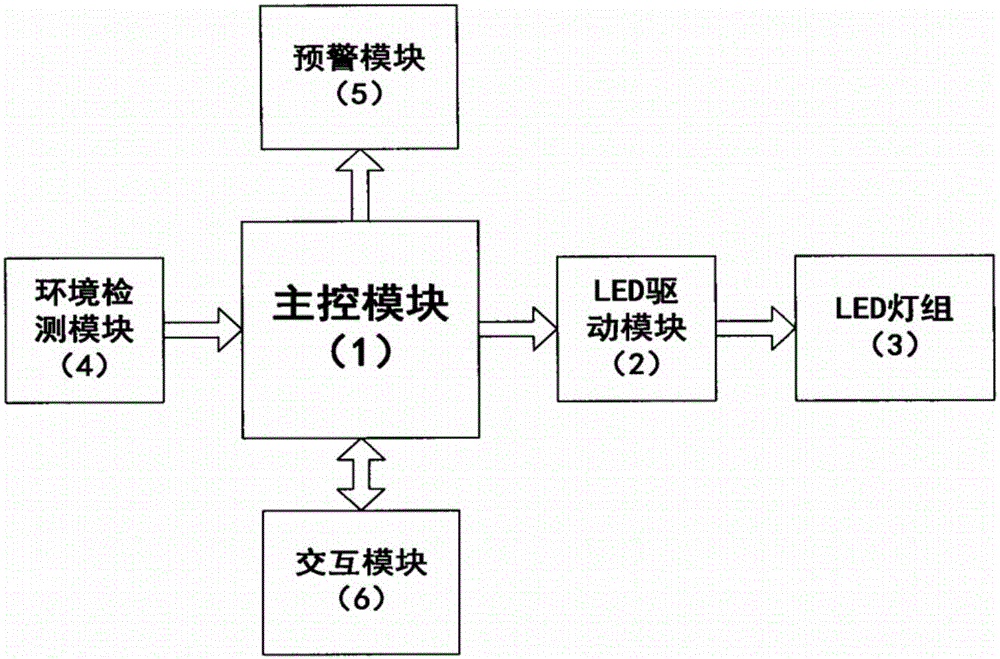

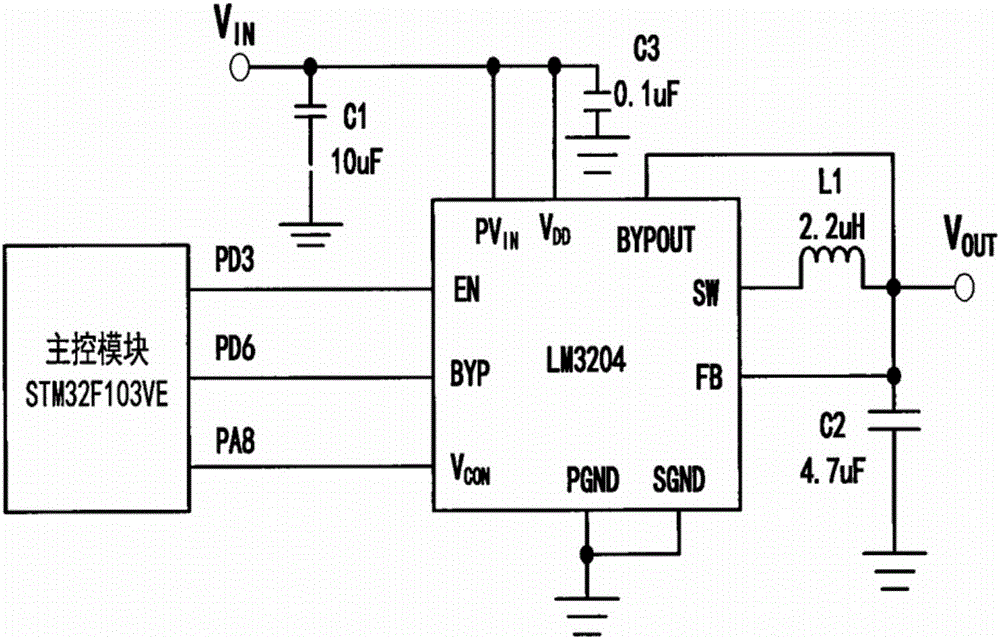

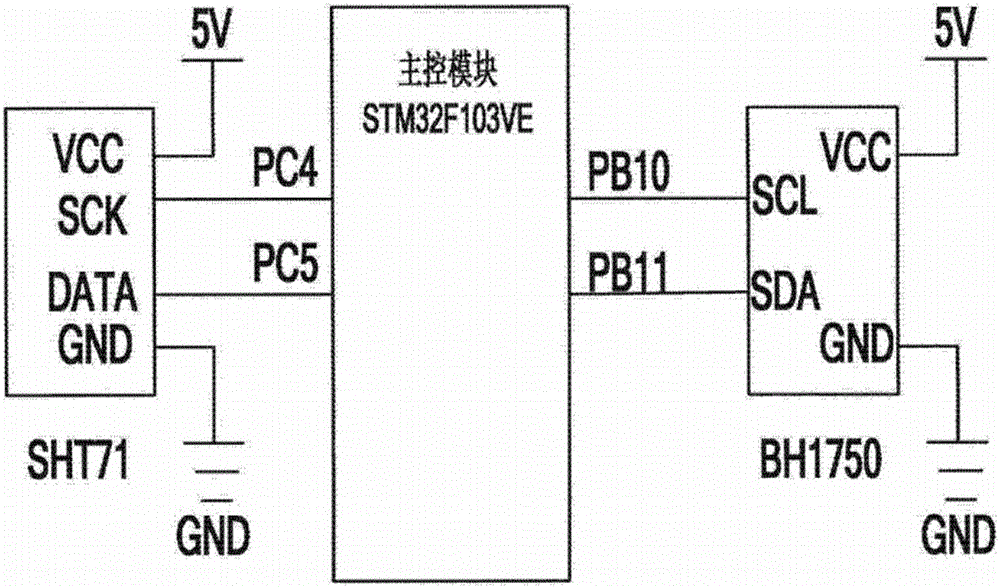

Intelligent LED lighting system for duckling culture

InactiveCN106413174AImprove fitnessMeet the lighting conditionsElectrical apparatusElectroluminescent light sourcesLighting systemColor temperature

The invention discloses an intelligent LED lighting system for duckling culture. The intelligent LED lighting system comprises a master control module (1) and also comprises an LED driving module (2), an LED lamp group (3), an environment detection module (4), an early warning module (5) and an interaction module (6), wherein the LED driving module (2) is connected with an output end of the master control module (1), the LED lamp group (3) is connected with the LED driving module (2), the environment detection module (4) is connected with an input end of the master control module (1), the early warning module (5) is connected with an output end of the master control module (1), the interaction module (6) is connected with an output end of the master control module (1), the LED driving module (2) adopts a buck type DC / DC converter LM3402 to design an LED driving circuit so that the light brightness and intensity of the LED lamp group (3) are changed, the LED lamp group (3) comprises red LED lamps and blue LED lamps which are in 15 rows and 16 lines, the proportion of the red lamps and the blue lamps is 7:1, moreover, five white LED lamps are jointly used for generating a light condition with a color temperature range of 4,000-5,000K for duckling culture.

Owner:严立

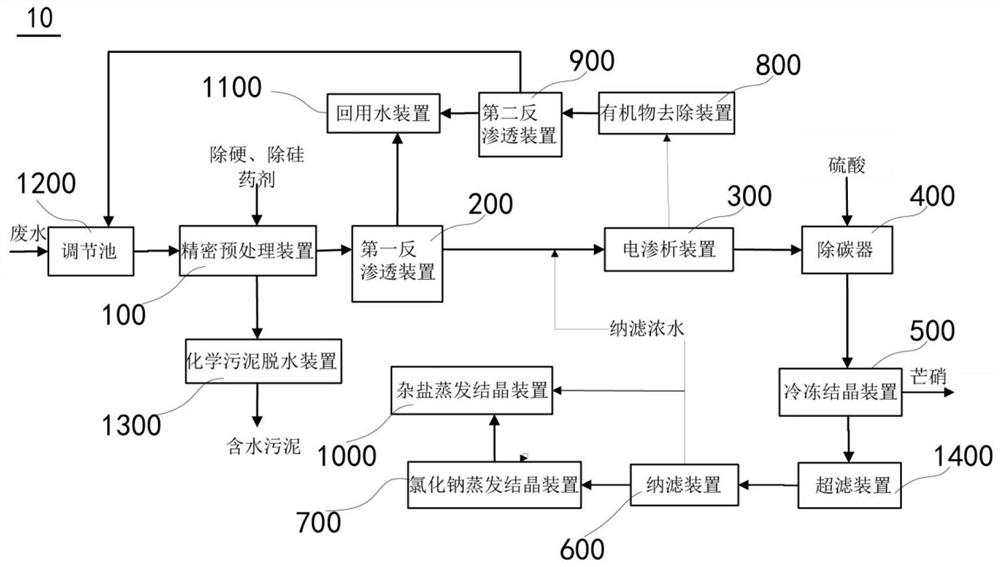

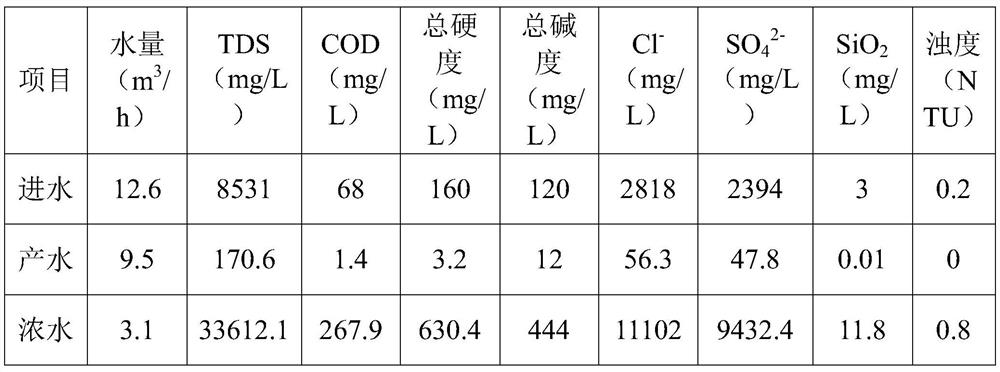

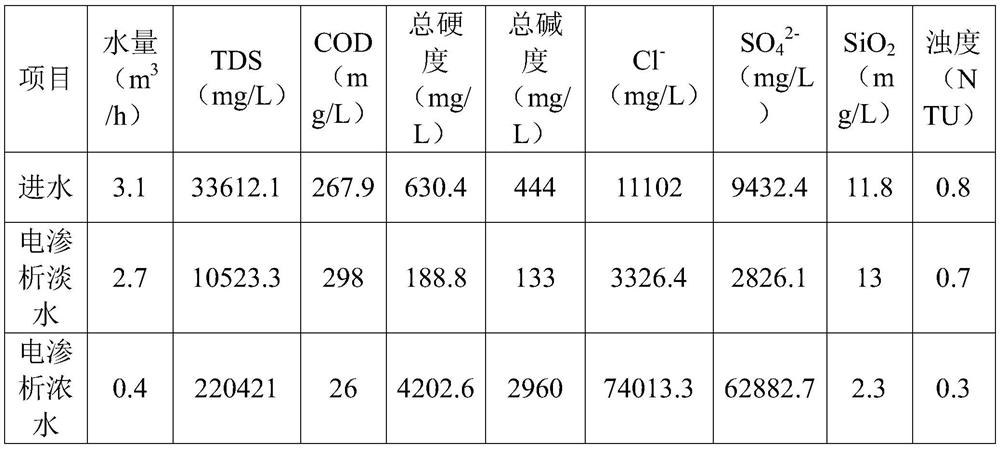

Freezing salt separation system and freezing salt separation method

PendingCN111908677AGuaranteed uptimeMild operating conditionsWater contaminantsAlkali metal sulfite/sulfate purificationReverse osmosisEvaporation

The invention discloses a freezing salt separation system and a freezing salt separation method. The freezing salt separation system comprises a precision pretreatment device, a first reverse osmosisdevice, an electrodialysis device, a carbon remover, a freezing crystallization device, a nanofiltration device, a sodium chloride evaporation crystallization device, an organic matter removal device,a second reverse osmosis device and a miscellaneous salt evaporation crystallization device, wherein the precision pretreatment device, the first reverse osmosis device, the electrodialysis device, the carbon remover, the freezing crystallization device, the nanofiltration device, the sodium chloride evaporative crystallization device and the carnallite evaporative crystallization device are connected in sequence; and the second reverse osmosis device and the organic matter removal device are sequentially connected with the electrodialysis device. The freezing salt separation system and method can achieve the purposes of being short in technological process, stable in operation, relatively mild in operation condition, low in investment cost, low in final miscellaneous salt rate and free of emission.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

A kind of molten salt electrolysis method for preparing aluminum-scandium master alloy

The invention belongs to the technical field of molten salt electrolysis, and in particular relates to a molten salt electrolysis method for preparing an aluminum-scandium intermediate alloy. The molten salt electrolysis method comprises the following steps: in a point charging type pre-baked anode molten salt electrolytic tank, by taking fluoride molten salt M3AlF6-AlF3 as a basic electrolyte system and taking aluminum oxide and a scandium-containing compound as raw materials, performing electrolysis in different cathode regions in the same electrolytic tank to dissolve out metal aluminum and metal scandium by adopting an independent charging mode, and alloying metal aluminum and metal scandium to obtain an aluminum-scandium intermediate alloy product of which the scandium content is 1.5-3.0% and the total mass percentage of aluminum and scandium is more than 99%. The aluminum-scandium intermediate alloy prepared by using the method disclosed by the invention is adjustable in component proportion, is suitable for additives of various scandium-containing aluminum alloys and other alloys, and ensures that the mechanical performance of the alloys can be significantly improved and the problems that aluminum oxide or the scandium-containing compound at the tank bottom is easy to participate and the electrolytic tank cannot be operated stably for a long time can be solved; and the method disclosed by the invention is low in production cost, high in automation degree and high in production efficiency.

Owner:CENT SOUTH UNIV

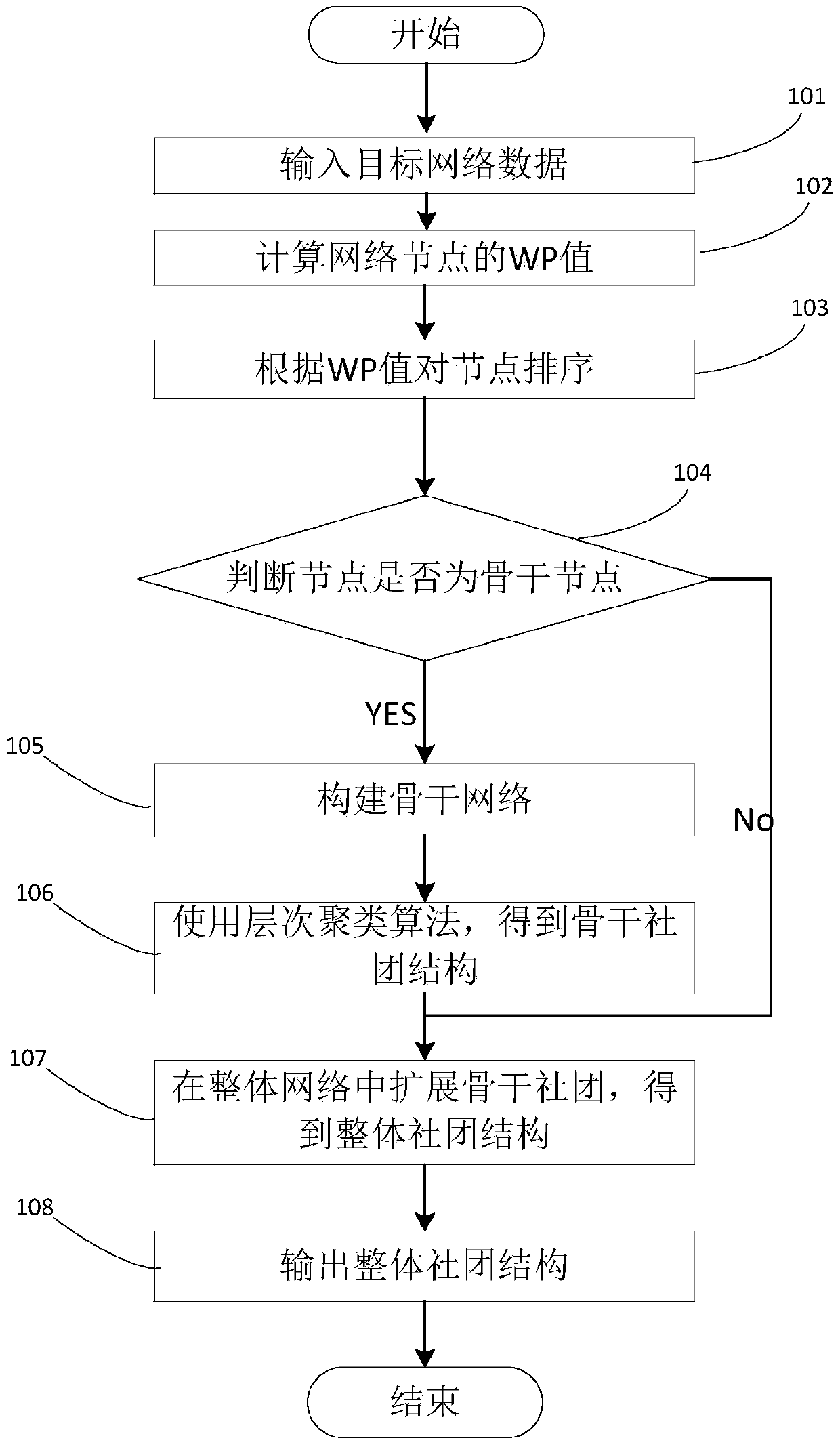

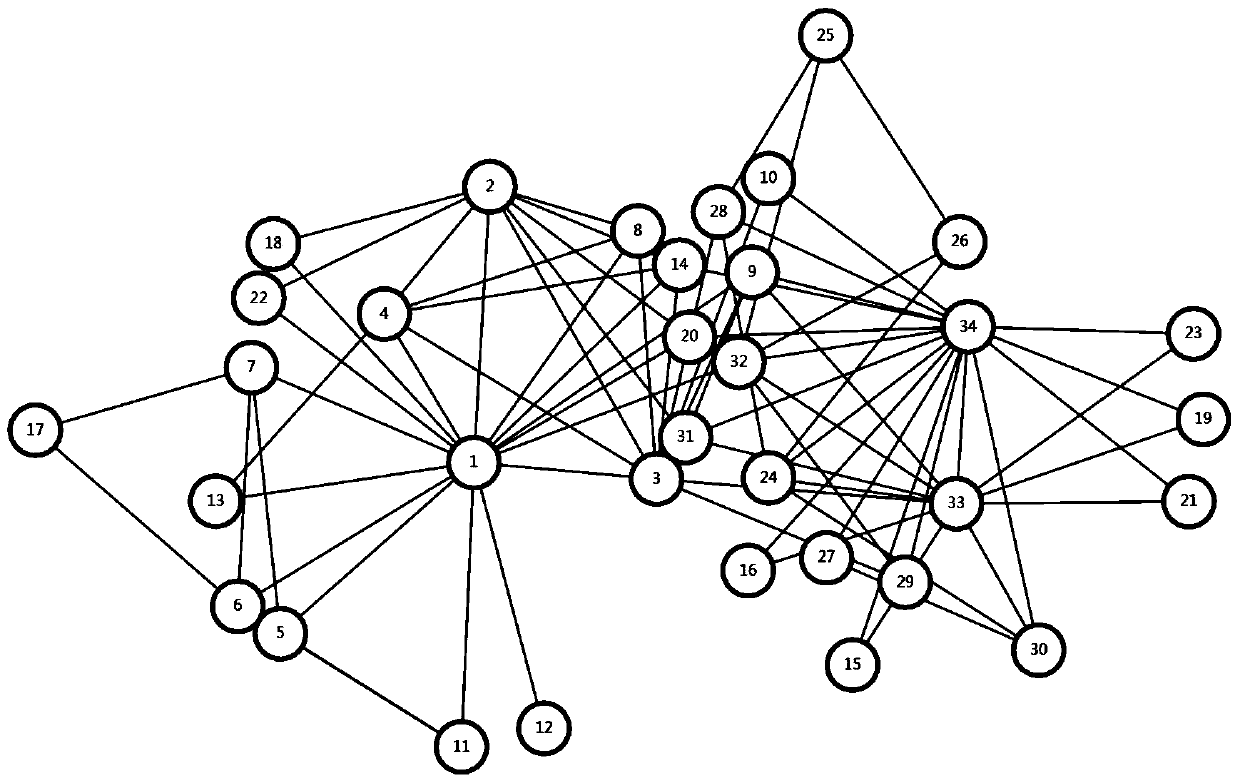

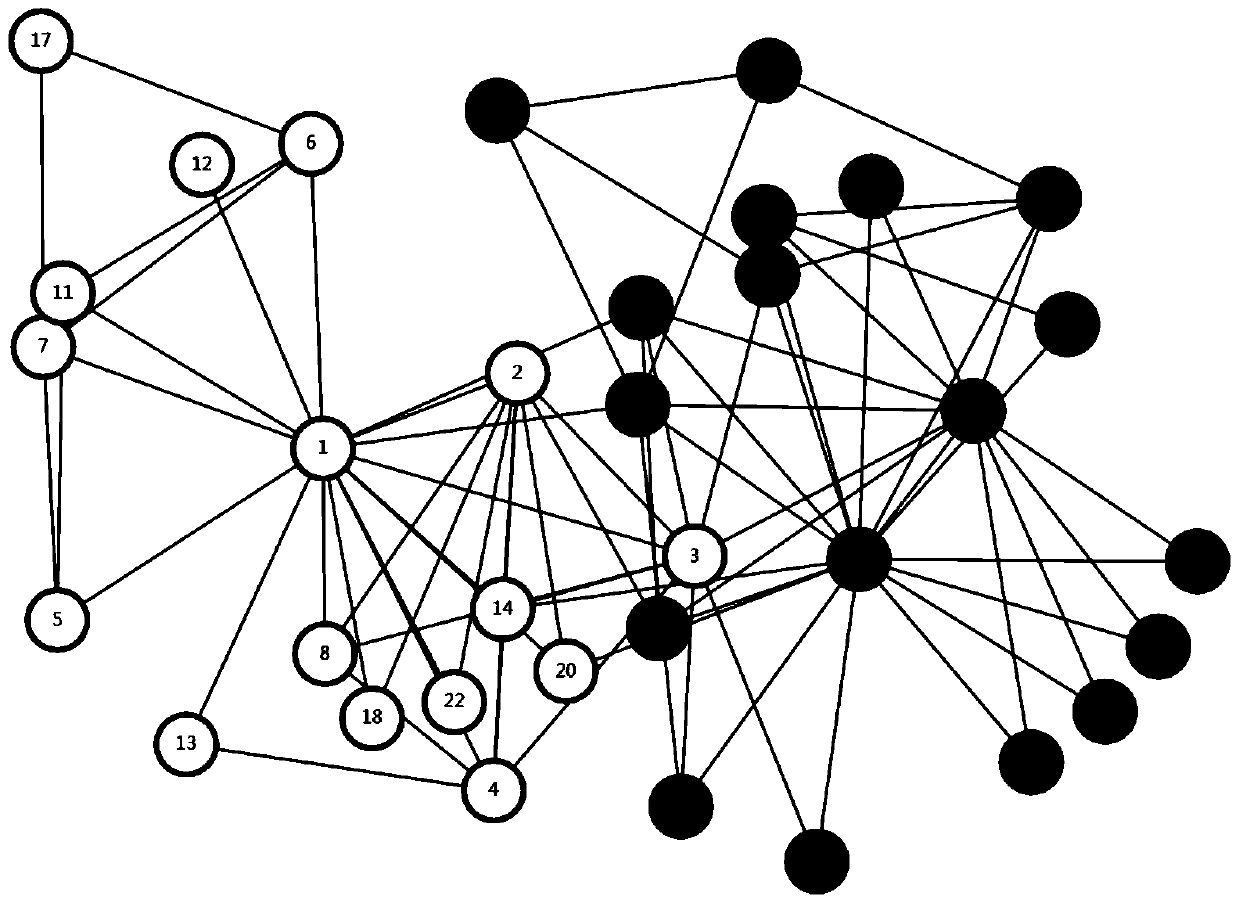

Community detection method based on backbone network extension

InactiveCN105162648BReduce computational complexityReduce computing scaleData switching networksComplex networkPagerank algorithm

The invention discloses a community detection method based on backbone network extension, which is used for rapid community discovery in large-scale complex networks. The present invention mainly includes: use the improved PageRank algorithm (WP) based on node weight to calculate the input network, select the node whose WP value is greater than the threshold as the backbone node of the network; traverse the whole network, extract the backbone node and connect any two backbone nodes The edges of the nodes constitute the backbone network; the hierarchical clustering algorithm is run in the backbone network to obtain the backbone community structure; the extension algorithm is used to extend the backbone community to the entire network to obtain the community structure of the overall network. The invention narrows the operating range of the hierarchical clustering algorithm to the backbone network, avoids clustering in the whole network, has relatively small time complexity, and is suitable for community discovery in large-scale complex networks. In addition, the present invention can quickly capture the change details of the overall community by tracking the change of the backbone community, and is suitable for community discovery in a rapidly evolving network.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Fermented fishmeal fertilizer and production method thereof

InactiveCN1283594CPromote absorptionImprove balanceBio-organic fraction processingAnimal corpse fertilisersBiotechnologyMicroorganism

The invention discloses a kind of baking fish meal fertilizer and its production method. The use of organic fertilizer makes for the alteration of the physical properties of soil, and provides the proper environment of the growing of beneficial microbios, the surviving of beneficial enzymes in soil and the various biochemical reaction process, and prevents the soil fertility deterioration. In the invention, the organic fertilizer is made up of fish meal and base fertilizer by fermenting.

Owner:北海市福林绿色生物肥有限公司

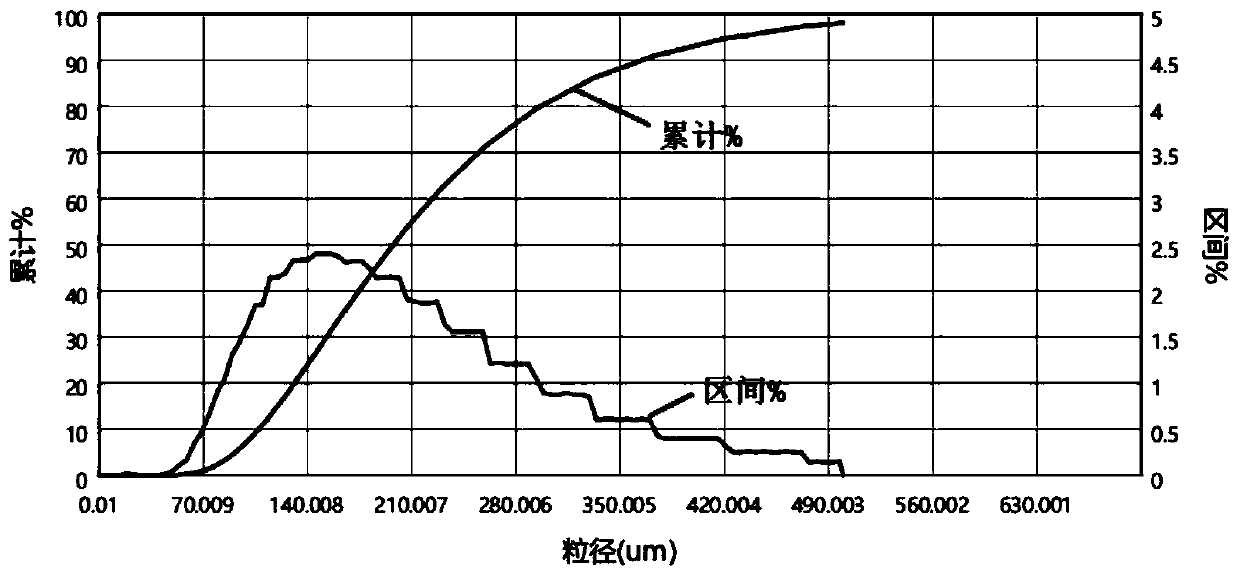

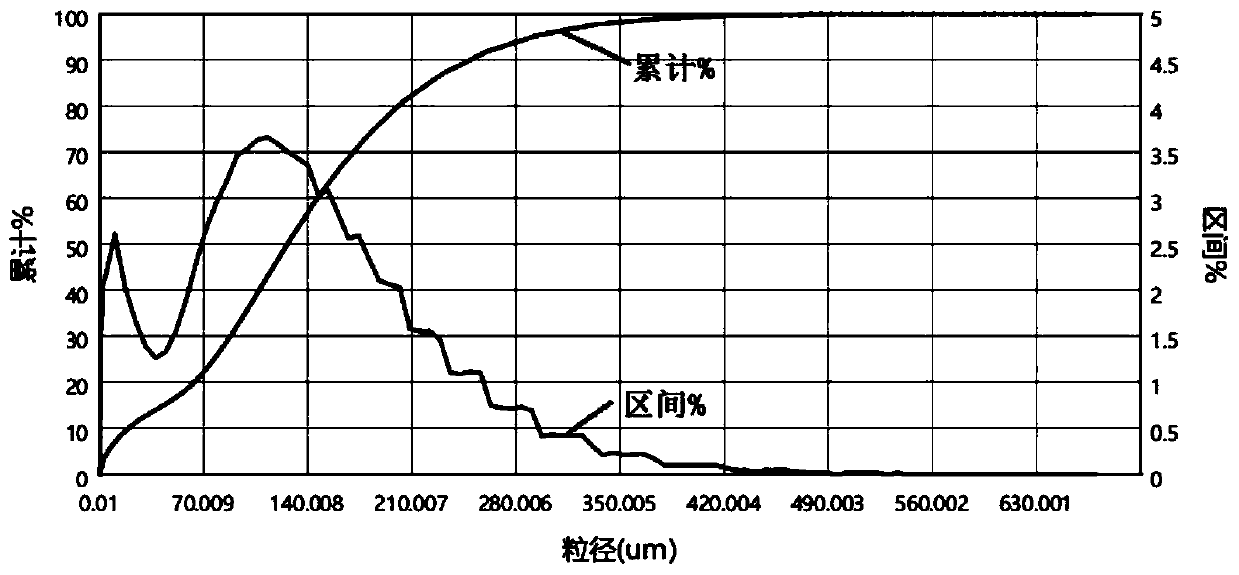

Preparation method of bimodal gradation zirconium powder

ActiveCN110479956ASimple production processEasy to implementMould handling/dressing devicesMicrometerCryogenic treatment

The invention relates to the technical field of preparation of bimodal concrete gradation powder and particularly relates to a preparation method of bimodal concrete gradation zirconium powder. The method comprises the following steps of heating zircon serving as raw sand, carrying out rapid cryogenic treatment to form a large number of micro cracks in the raw sand so as to increase the crushing speed of the raw sand in a ball milling process, and mixing the raw sand with raw sand free of rapid cryogenic treatment and carrying out ball milling treatment to obtain the zirconium powder with bimodal particle size distribution. According to the preparation method of the bimodal gradation zirconium powder, the peak particle size of the fine bimodal gradation zirconium powder is 7 micrometers to14 micrometers, and the peak particle size of the coarse bimodal gradation zirconium powder can be controlled by adjusting a raw sand particle size and ball milling time; and meanwhile, the process is simple, a conventional heating furnace and a conventional ball mill are required, the investment is small, the production cost is low, and the bimodal gradation powder suitable for different conditions can be obtained through raw sand and the control of process parameters.

Owner:江苏铸友锆钛科技有限公司 +1

A new process for the joint production of dimethylhexynediol and diacetone alcohol

ActiveCN109824478BAdjustable ratioLow investment costOrganic compound preparationHydroxy compound preparationDiacetone alcoholDiacetonamine

The invention provides a new technology for co-production of dimethyl hexylenediol and diacetone alcohol, and belongs to the technical field of organic fine chemical preparation. According to the technology, methylbutynol and acetone serve as raw materials and are subjected to a reaction under the catalytic effect of alkali in a reaction solvent, then hydrolysis and layering are conducted, and theproducts dimethyl hexylenediol and diacetone alcoho are obtained after an upper-layer oil phase is washed for dealkalization, neutralized and rectified; lower-layer alkali liquor is recycled after catalyst regeneration, and water generated in the process is used for washing and hydrolysis. By means of the technology, co-production of the dimethyl hexylenediol and diacetone alcohol can be achieved, the total yield of the dimethyl hexylenediol and diacetone alcohol on the acetone is about 96%, the yield of the dimethyl hexylenediol on the methylbutynol is about 93%, and the mole ratio of the dimethyl hexylenediol to the diacetone alcohol is larger than 0.22 and is adjustable. By means of the technology, fixed investment and production cost can be effectively lowered, the added value of products, the utilization rate and the market resilience of devices are significantly increased, and the economic benefit increment is considerable.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

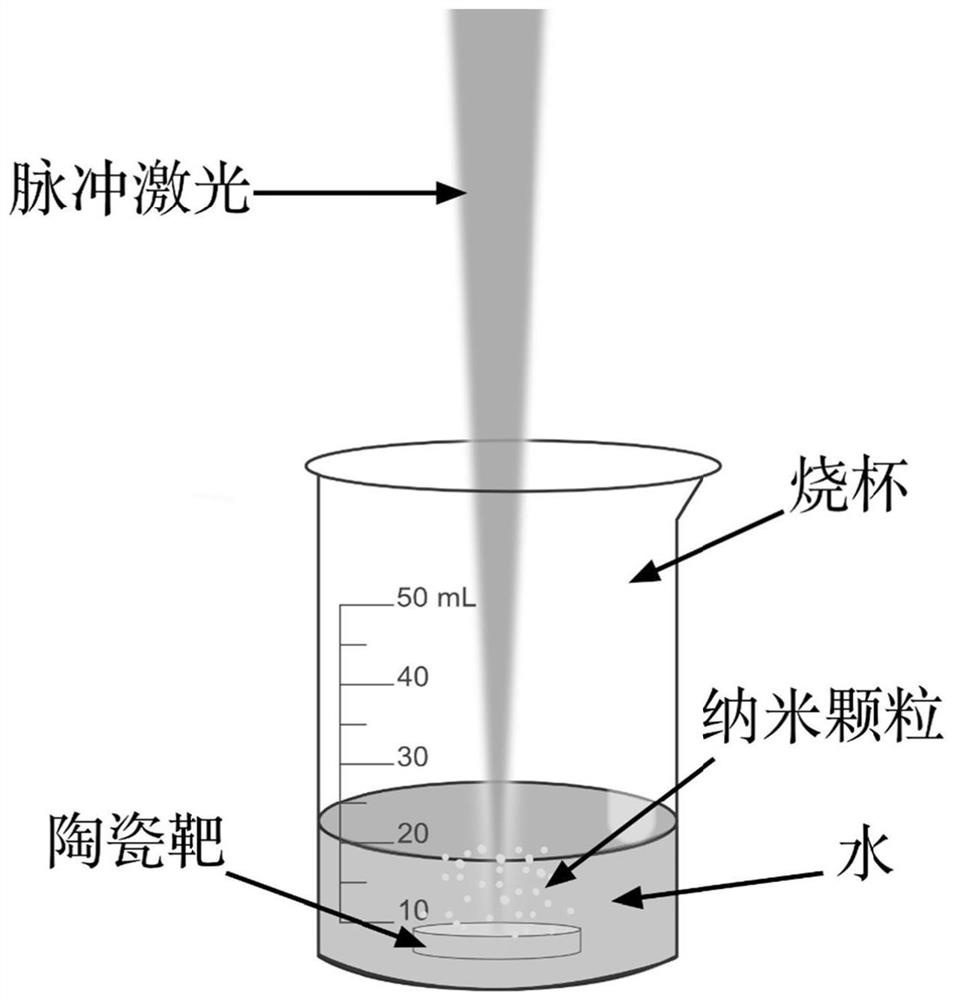

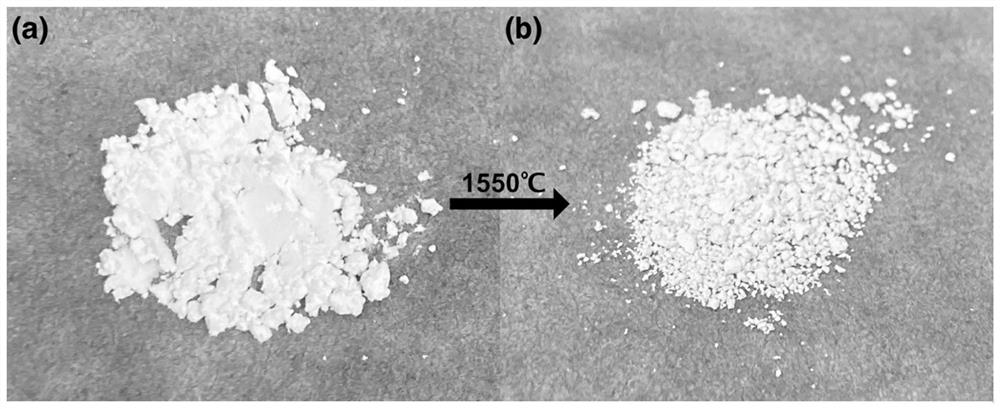

Nanocrystal, preparation method and application thereof

PendingCN113897196ASmall particle sizeLow cytotoxicityNanoopticsLuminescent compositionsGadolinium oxideCytotoxicity

The invention discloses a nanocrystal, a preparation method and application thereof. The nanocrystal is a monoclinic crystal phase erbium oxide doped gadolinium oxide nanocrystal. The nanocrystal provided by the invention is a monoclinic crystal phase erbium oxide doped gadolinium oxide nanocrystal, and has the advantages of small particle size and controllable erbium ion doping. The monoclinic crystal phase erbium oxide doped gadolinium oxide nanocrystal is prepared by combining a solid-phase sintering method with a liquid-phase laser ablation technology, wherein the method is simple in preparation process and environmentally friendly. The nanocrystal has low cytotoxicity and an excellent up-down conversion dual-mode fluorescence function, can be applied to the fields of biological imaging and LED illumination, and is an excellent fluorescent material.

Owner:SUN YAT SEN UNIV

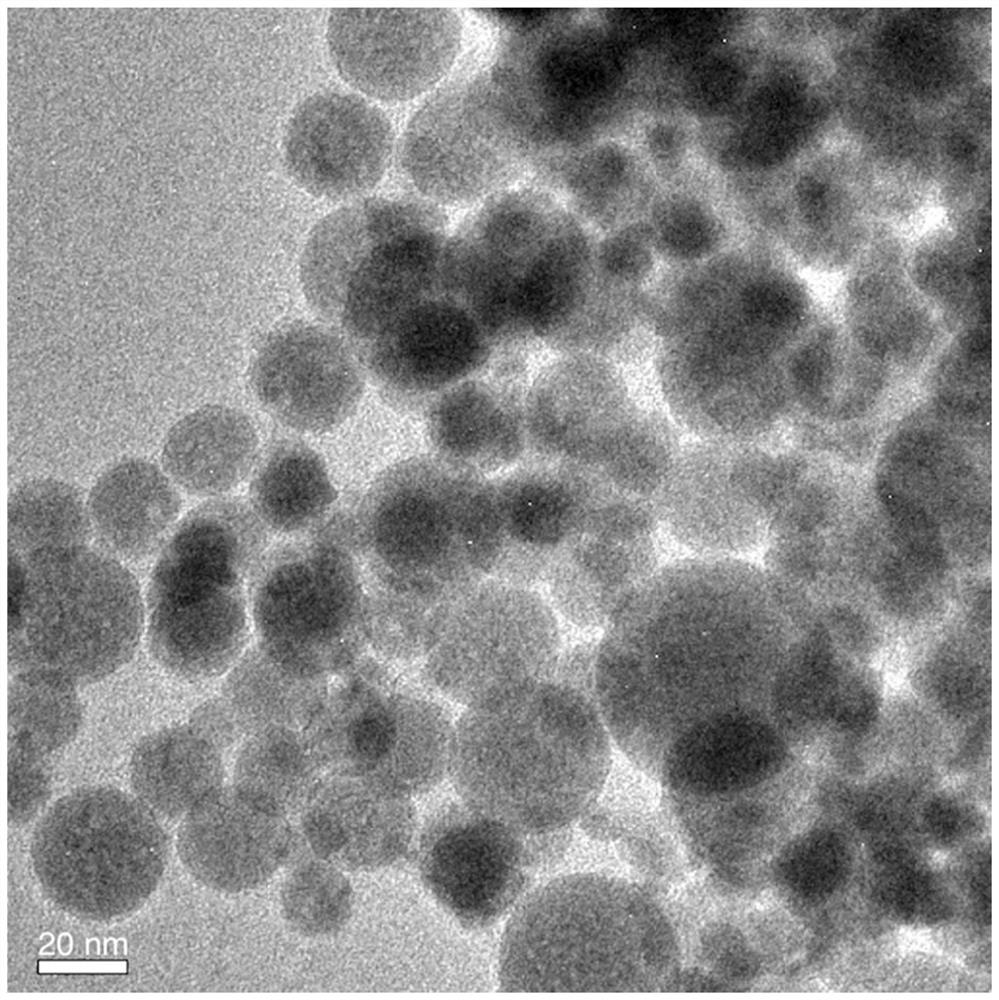

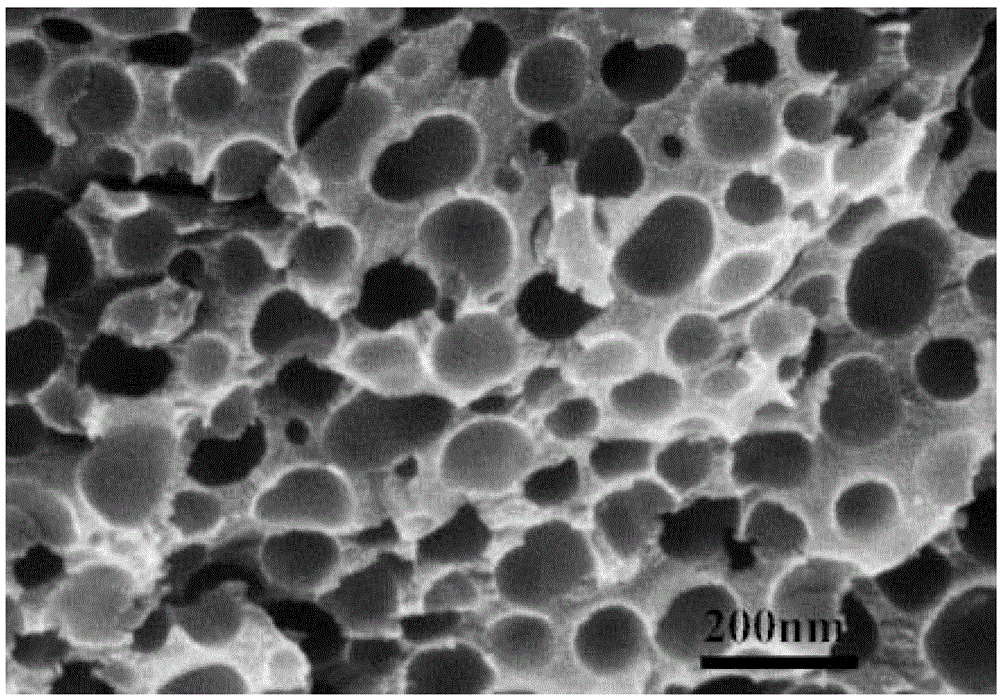

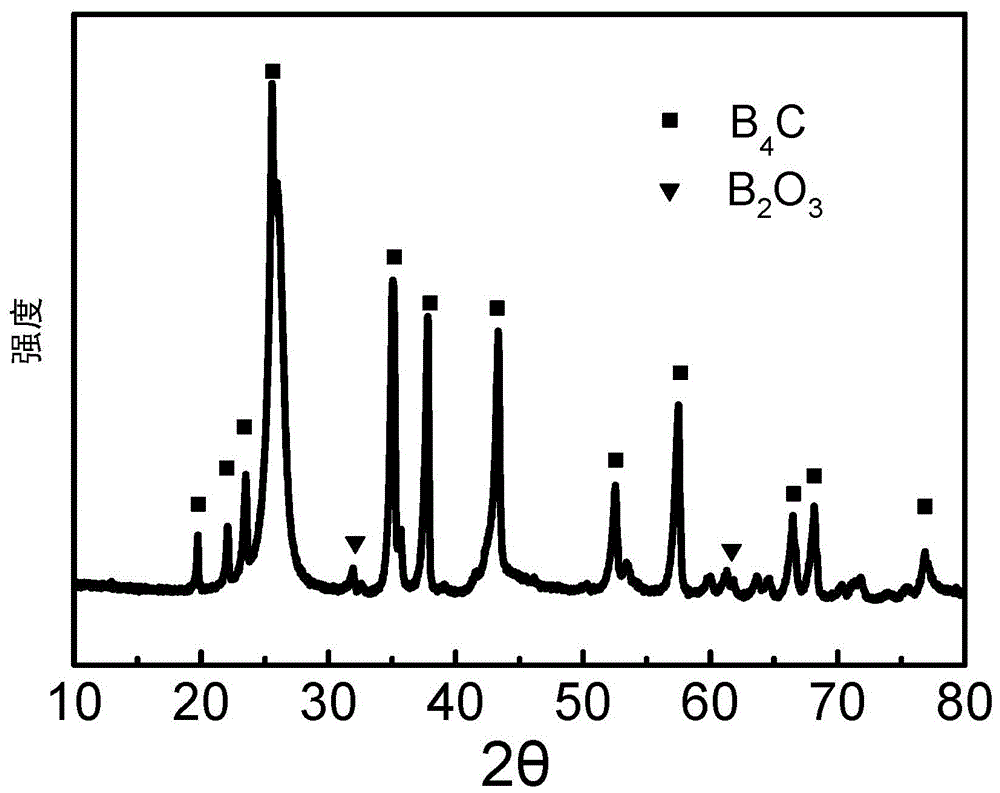

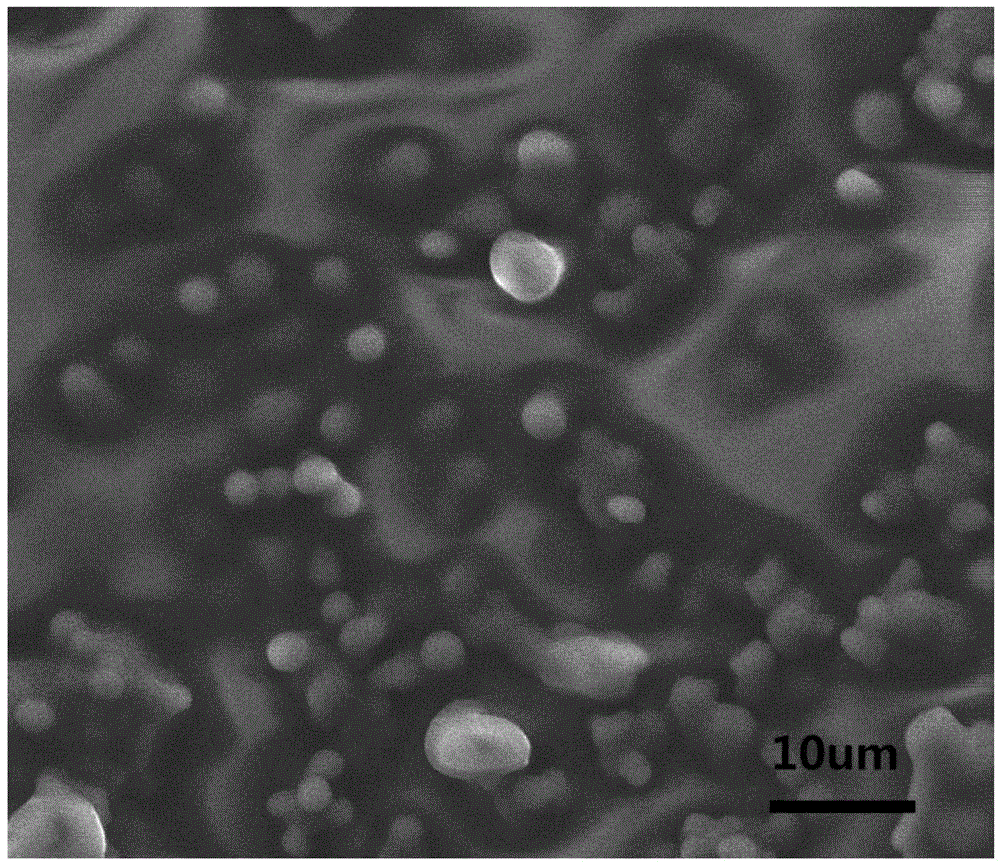

A method for synthesizing boron carbide powder at low temperature with high yield

The invention relates to a method for synthesizing boron carbide powder in high yield at low temperature. The method comprises the following steps: respectively measuring boric acid and polyvinyl alcohol according to a molar ratio of (4 to 7) : 10, mixing and stirring the boric acid and glycerol to be completely dissolved, adding alkali, adjusting the pH to 4 to 6, and obtaining a boric acid solution; mixing and stirring the polyvinyl alcohol and water to be completely dissolved, and obtaining a polyvinyl alcohol solution; mixing and stirring the obtained boric acid solution and the obtained polyvinyl alcohol solution, and heating and evaporating a solvent to completely form gel; drying the obtained gel to obtain dry gel; preserving the heat of the dry gel for 2 to 4 hours in a vacuum or inert atmosphere at the temperature of 500 to 700 DEG C, and carrying out the dissociation; preserving the heat of a dissociation product in a vacuum or inert atmosphere at the temperature of 1300 to 1500 DEG C for 3 to 5 hours, and carrying out the carbon thermal reduction for the dissociation product, and obtaining boron carbide powder. By adopting the method, the problems that B2O3 is severely volatilized and lost and the concentration of boric acid in a boric acid-polyvinyl alcohol system is extremely low in the subsequent process of gel of a boric acid-glycerol system are simultaneously overcome.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method for manufacturing polyester staple fibers through recycled polyester bottles

InactiveCN103305960BSave natural resourcesReduce white pollutionFilament forming substance formingMelt spinning methodsPolyesterFiber

The invention discloses a method for manufacturing polyester staple fibers through recycled polyester bottles. The method comprises the following steps of: recycling waste polyester bottles, and performing crushing, cleaning, burdening, melt-extruding, spinning-extruding, drawing, drying, sizing and cutting on the recycled polyester bottles to obtain the polyester staple fibers. The production method disclosed by the invention not only saves natural resources, but also alleviates white pollution and protects the environment, thereby having good economic and social benefits, and the proportions of the raw materials can be adjusted to obtain products with given specifications. The product is a superior product according to the product grade of the textile raw material product standard of China, and is capable of replacing staple fibers produced by conventional production methods.

Owner:FUJIAN SANDA FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com