Recombinant microorganism having increased d(-) 2,3-butanediol productivity, and method for producing d(-) 2,3-butanediol by using same

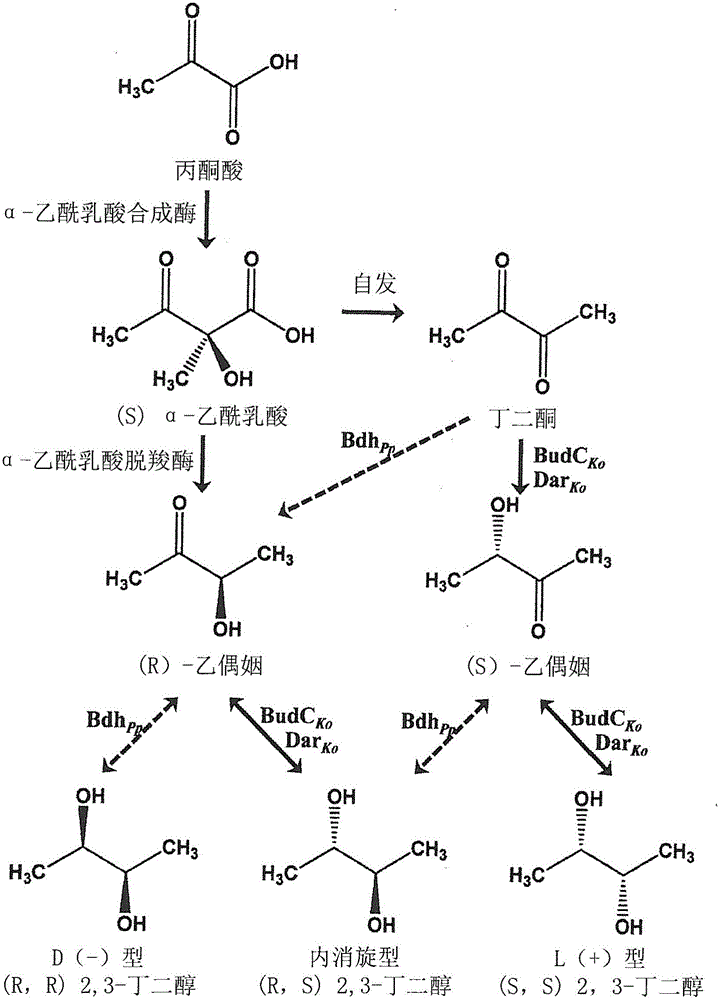

一种重组微生物、生产方法的技术,应用在D(-)型2,3-丁二醇的生产率得到增强的重组微生物及利用其的D(-)型2,3-丁二醇的生产领域,能够解决无光学活性、多粘类芽孢杆菌高营养成分的要求生产率及产量低等问题,达到生产率高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] Preparation method of D(-) type 2,3-butanediol

[0050] The present invention relates to a method for preparing D(-)-type 2,3-butanediol, which comprises the steps of inoculating the recombinant microorganism of the present invention and culturing the above-mentioned recombinant microorganism. The above-mentioned production method of D(-)-type 2,3-butanediol may further comprise the step of recovering the produced D(-)-type 2,3-butanediol.

[0051] The preparation method of 2,3-butanediol

[0052] The present invention relates to a method for producing a desired 2,3-butanediol having a composition of 2,3-butanediol isomers using the recombinant microorganism of the present invention, ie, without inhibiting the use of acetoin for When a gene encoding an enzyme for converting meso-2,3-butanediol is introduced into a gene encoding an enzyme for converting acetoin to D(-)-type 2,3-butanediol 2,3-butanediol containing meso-type 2,3-butanediol and (D)-type 2,3-butanedio...

specific Embodiment

[0055] Advantages and features of the present invention, and methods for achieving them, will become apparent by reference to the embodiments described in detail. However, the present invention is not limited to the embodiments disclosed below, but can be implemented in other various manners, and the present embodiments are only used to complete the disclosure of the present invention, and to make those of ordinary skill in the art to which the present invention pertain completely comprehensible. The invention is provided with an understanding of the scope of the invention, and the invention is only defined by the scope of the claimed scope of the invention.

[0056] Materials and Methods

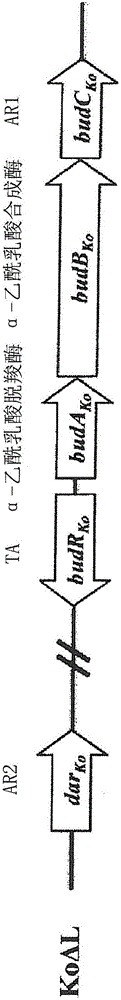

[0057] Preparation of Klebsiella oxytoca KCTC12133BP△ldhA(KO△L) strain

[0058] The Klebsiella oxytoca KCTC12133BPΔldhA(KOΔL) strain lacking lactate dehydrogenase (lactate dehydrogenase, LdhA) was prepared by the following method. First, in order to clone the lactate dehydrogenase of Kl...

experiment example 1

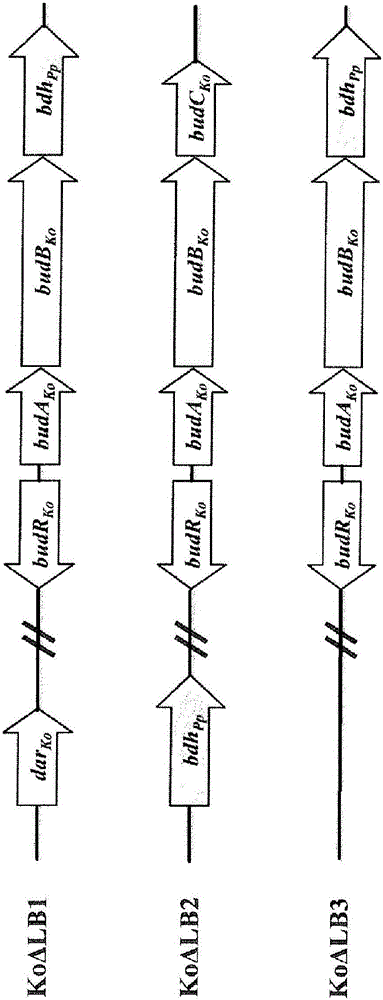

[0075] Experimental Example 1: Preparation of Recombinant Microorganisms

[0076] Klebsiella oxytoca KCTC12133BP△ldhAbudC Ko ::bdh Pp (Ko△LB1) strain

[0077] BdhPp, which is an acetoin reductase derived from Paenibacillus polymyxa, is an enzyme belonging to a medium-chain dehydrogenase / reductase. Recombinant Klebsiella oxytoca utilizes bdh as the gene encoding it Pp , to replace budCKo, which is one of the endogenous acetoin reductases of KCTC12133BP, the recombinant Klebsiella oxytogens was prepared by the following method. Specifically, based on Klebsiella oxytoca KCTC12133BPΔldhA(KoΔL), it was prepared by the following method, and the genome schema of the above strain is as follows image 3 shown. Bdh derived from the above Paenibacillus polymyxa KCTC1663 Pp The amino acid sequence of is described in SEQ ID NO.20, as the bdh of the gene encoding it Pp The base sequence is SEQ ID NO. 21 (Table 4).

[0078] Table 4

[0079]

[0080] First, in order to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com