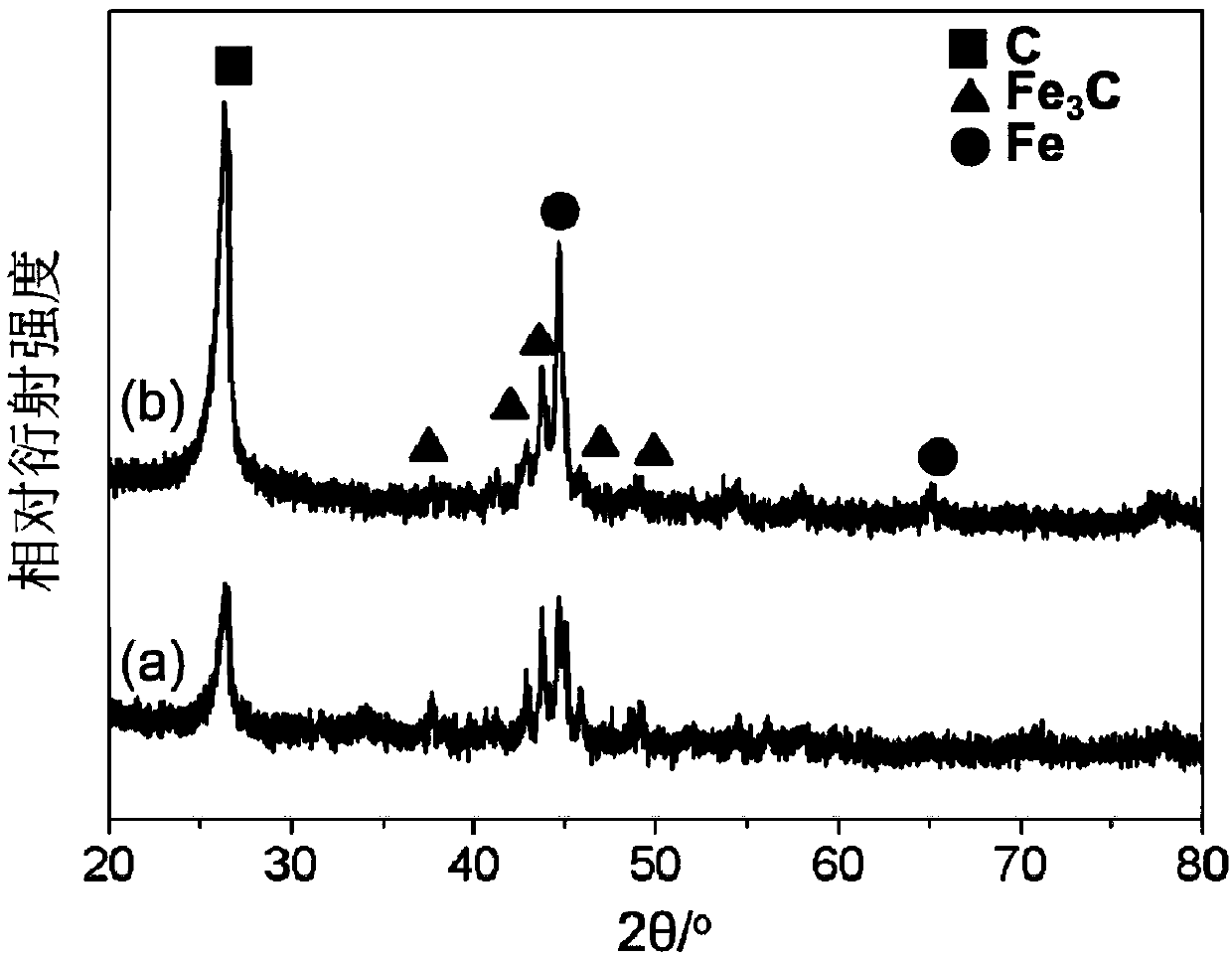

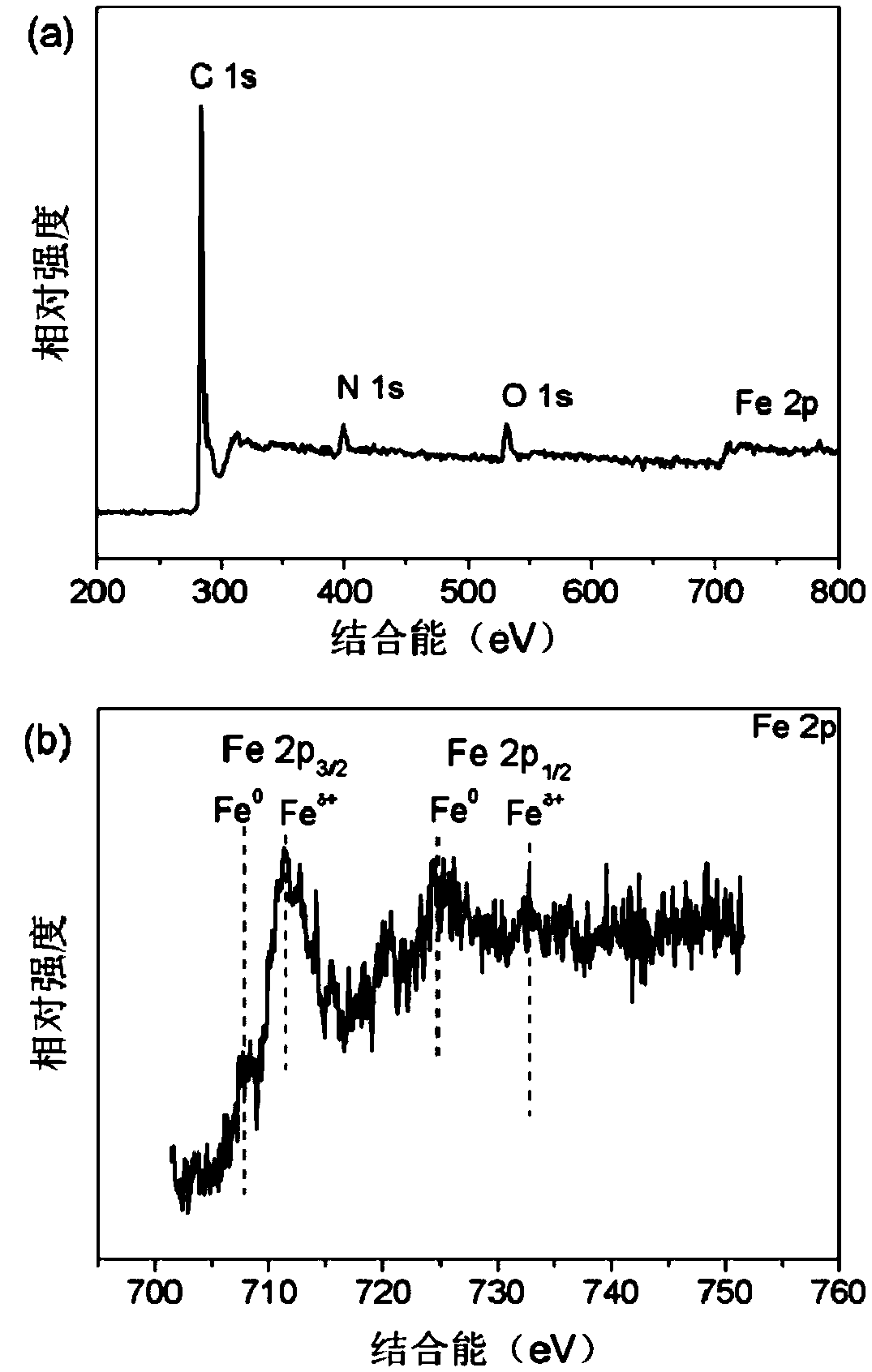

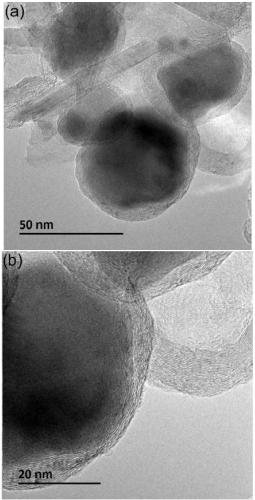

Nano-composite of carbon-coated iron and iron carbide, and preparation method for same

A nano-composite material and composite material technology are applied in the field of carbon-coated iron and iron carbide nano-composite materials and their preparation, which can solve the problems of poor coating, limited application of materials, and only remaining iron mass fraction, and achieve environmental friendliness. , broad application prospects, the effect of reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the present invention may also include step S5, wherein the product obtained in step S4 is purified in an acidic solution to remove incompletely coated iron and iron carbide cores.

[0039] Wherein the acidic solution used in step S5 is hydrochloric acid, sulfuric acid or hydrofluoric acid aqueous solution, and the concentration range is 0.1-5 mol / L.

Embodiment 1

[0041] Weigh 10mmol Fe(OH) 3 10mmol of ethylenediaminetetraacetic acid was added to 100mL of deionized water, stirred at 80°C to obtain a homogeneous solution, 30mmol of dicyandiamide was added and continued to heat and evaporate to dryness, and the solid was ground to obtain the first precursor.

[0042] Put the obtained first precursor in the porcelain boat, then place the porcelain boat in the constant temperature zone of the tube furnace, pass nitrogen gas, the flow rate is 100mL / min, and raise the temperature to 700°C at a rate of 5°C / min, and keep the temperature for 3 hours Stop heating, and cool to room temperature under a nitrogen atmosphere to obtain a carbon-coated composite material.

[0043] The obtained carbon-coated composite material and dicyandiamide were added into 40 mL of deionized water at a mass ratio of 1:1, stirred at 80°C and evaporated to dryness, and the solid was ground to obtain a second precursor.

[0044] Put the second precursor in the porcelai...

Embodiment 2

[0047] Weigh 10mmol Fe(OH) 3 10mmol of ethylenediaminetetraacetic acid was added to 100mL of deionized water, stirred at 70°C to obtain a homogeneous solution, 30mmol of dicyandiamide was added and evaporated to dryness, and the solid was ground to obtain a precursor.

[0048] Put the obtained precursor in the porcelain boat, then place the porcelain boat in the constant temperature zone of the tube furnace, pass nitrogen gas, flow rate 100mL / min, and raise the temperature to 800°C at a rate of 5°C / min, stop heating after 3 hours of constant temperature , cooled to room temperature under a nitrogen atmosphere to obtain a carbon-coated composite material.

[0049] The obtained carbon-coated composite material and dicyandiamide were added into 60 mL of deionized water at a mass ratio of 1:1, stirred at 80°C and evaporated to dryness, and the solid was ground to obtain a second precursor.

[0050] Put the second precursor in the porcelain boat, then place the porcelain boat in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| loss rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com