A kind of molten salt electrolysis method for preparing aluminum-scandium master alloy

A technology of molten salt electrolysis and master alloy, which is applied in the field of molten salt electrolysis for the preparation of aluminum-scandium master alloy and the preparation of aluminum-scandium master alloy, which can solve the waste of raw materials, affect the stable operation of the electrolytic cell, and cannot meet the high cost of the production process. Efficiency operation and other issues to achieve the effect of reducing production costs, high degree of automation, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

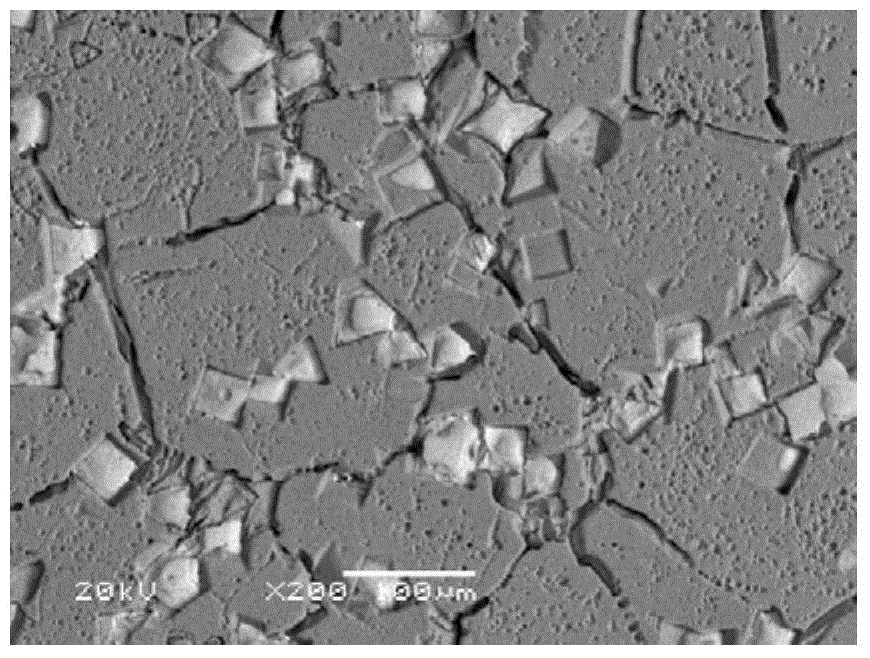

Embodiment 1

[0027] In the 160kA prebaked anode molten salt electrolyzer with point feeding, the fluoride molten salt 80%Na 3 AlF 6 -20%AlF 3 as the basic electrolyte, Al 2 o 3 with Sc 2 o 3 The cutting amount is 98.5:1.5 by mass percentage, the Sc 2 o 3 Add from the middle feeding point in the tank, Al 2 o 3 Add from other feeding points, at electrolysis temperature 940°C, current density 0.75A / cm 2 , under the condition that the pole distance is 4cm, the aluminum-scandium master alloy product with a mass percentage of scandium metal of 1.65% and a total mass percentage of aluminum and scandium of 99.2% can be obtained at the cathode. The electrolytic cell runs smoothly and the cell Al does not appear at the bottom 2 o 3 or Sc 2 o 3 precipitation phenomenon.

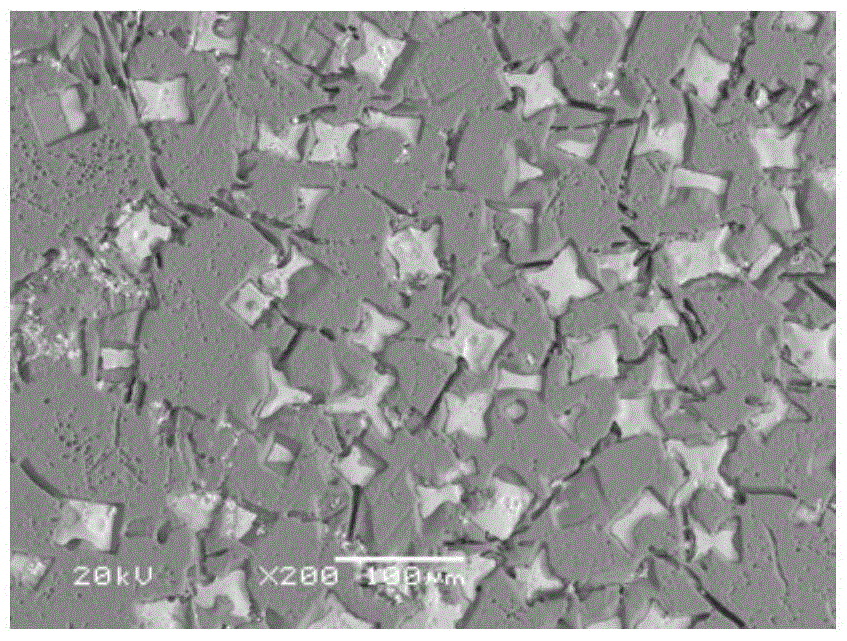

Embodiment 2

[0029] In the 160kA prebaked anode molten salt electrolyzer with point feeding, the fluoride molten salt 80%Na 3 AlF 6 -8% Li 3 AlF 6 -12%AlF 3 as the basic electrolyte, Al 2 o 3 with ScCl 3 The blanking amount is 96.2:3.8 by mass percentage, with ScCl 3 Add from the middle feeding point in the tank, Al 2 o 3 Add from other feeding points, at electrolysis temperature 945°C, current density 0.85A / cm 2 , under the condition that the pole distance is 4cm, an aluminum-scandium master alloy product with a metal scandium mass percentage content of 2.13% and a total mass percentage content of aluminum and scandium of 99.5% can be obtained at the cathode. The electrolytic cell runs smoothly, and the cell Al does not appear at the bottom 2 o 3 or ScCl 3 precipitation phenomenon.

Embodiment 3

[0031] In the 160kA prebaked anode molten salt electrolyzer with point feeding, the fluoride molten salt 66%Na 3 AlF 6 -16%K 3 AlF 6 -18%AlF 3 as the basic electrolyte, Al 2 o 3 with ScF 3 The cutting amount is 97.5:2.5 by mass percentage, the ScF 3 Add from the middle feeding point in the tank, Al 2 o 3 Add from other feeding points, at electrolysis temperature 900°C, current density 0.88A / cm 2, under the condition that the pole distance is 4cm, an aluminum-scandium master alloy product with a metal scandium mass percentage content of 1.97% and a total mass percentage content of aluminum and scandium of 99.6% can be obtained at the cathode. The electrolytic cell runs smoothly, and the cell Al does not appear at the bottom 2 o 3 or ScF 3 precipitation phenomenon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com