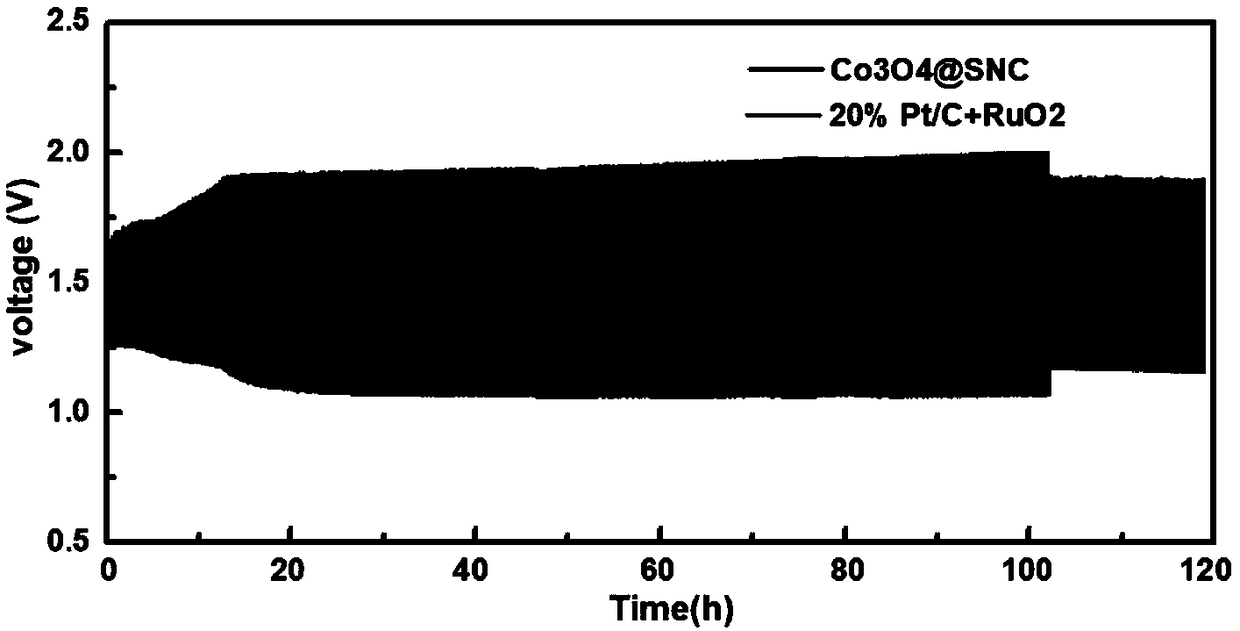

Carbon-doped transition metal oxide composite material and preparation method and application thereof

A technology of transition metals and composite materials, applied in the field of electrochemistry, can solve the problems of long precursor preparation cycle, large consumption of organic solvent, complicated operation, etc., and achieve the effect of promoting reaction kinetics, strengthening low-temperature oxidation process, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1) Add sodium alginate to deionized water, stir to form a uniform transparent viscous solution, and control the mass percent concentration of sodium alginate to 1.0%;

[0042] 2) The sulfur and nitrogen source is added to the nickel sulfate solution with a mass fraction of 3%, and stirred to form a uniform green solution, wherein the sulfur and nitrogen source is thiourea, and the amount added is 1 / 2 of the quality of sodium alginate, mixed with the nickel sulfate The mass ratio is 1:6;

[0043] 3) adding the sodium alginate solution in step 1) dropwise to the green solution in step 2), stirring and then standing still to form a tubular hydrogel;

[0044] 4) The hydrogel in step 3) is filtered, washed with deionized water, and freeze-dried to obtain a xerogel;

[0045] 5) The xerogel obtained in step 4) is placed in a tube furnace for carbonization treatment under an argon atmosphere, and naturally cooled to room temperature to obtain pyrolysis clinker. Among them, th...

Embodiment 2

[0048] 1) Add sodium alginate to deionized water, stir to form a uniform transparent viscous solution, and control the mass percent concentration of sodium alginate to 0.5%;

[0049] 2) The sulfur and nitrogen source is added into the manganese sulfate solution with a mass fraction of 4%, wherein the sulfur and nitrogen source is stirred to form a uniform gray solution, wherein the sulfur and nitrogen source is thiourea, and the amount of addition is the quality of sodium alginate, and the amount of manganese nitrate The mass ratio is 1:3;

[0050] 3) adding the sodium alginate solution in step 1) dropwise to the gray solution in step 2), stirring and standing to form a tubular hydrogel;

[0051] 4) The hydrogel in step 3) is filtered, washed with deionized water, and freeze-dried to obtain a xerogel;

[0052] 5) The xerogel obtained in step 4) is placed in a tube furnace for carbonization treatment under a nitrogen atmosphere, and naturally cooled to room temperature to obta...

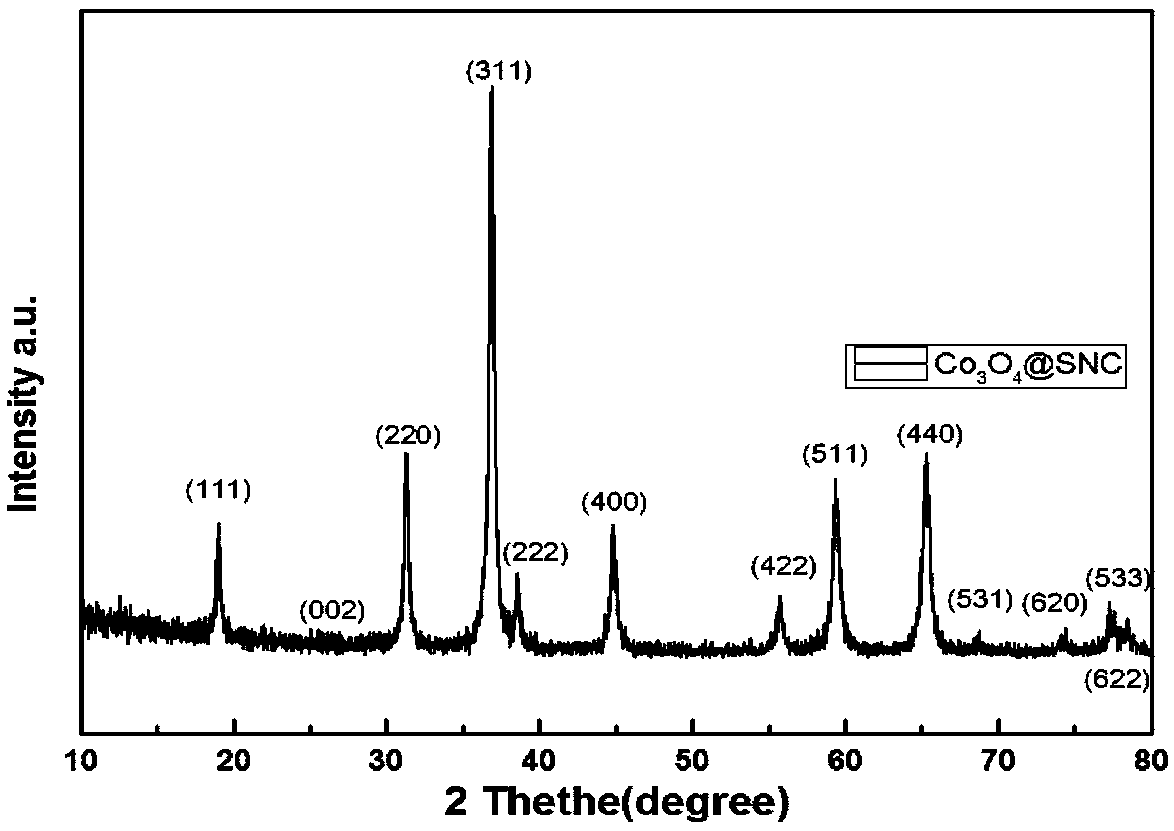

Embodiment 3

[0055] 1) Add sodium alginate to deionized water, stir to form a uniform transparent viscous solution, and control the mass percent concentration of sodium alginate to 1.5%;

[0056] 2) The sulfur and nitrogen source is added to the cobalt chloride solution with a mass fraction of 5%, and stirred to form a uniform pink solution, wherein the sulfur and nitrogen source is potassium thiocyanate, and the amount added is the quality of sodium alginate, mixed with cobalt chloride The mass ratio is 1:5;

[0057] 3) adding the sodium alginate solution in step 1) dropwise to the blood-red solution in step 2), stirring and then standing still to form a tubular hydrogel;

[0058] 4) The hydrogel in step 3) is filtered, washed with deionized water, and freeze-dried to obtain a xerogel;

[0059] 5) The xerogel obtained in step 4) is placed in a tube furnace for carbonization treatment under an inert atmosphere, and naturally cooled to room temperature to obtain pyrolysis clinker. Among t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com