Freezing salt separation system and freezing salt separation method

A technology of salt separation and freezing crystallization, applied in chemical instruments and methods, frozen water/sewage treatment, alkali metal sulfite/sulfate purification, etc. and other problems, to achieve the effect of mild operating conditions, shortened process flow, and good salt separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] This embodiment provides a method for freezing and separating salt.

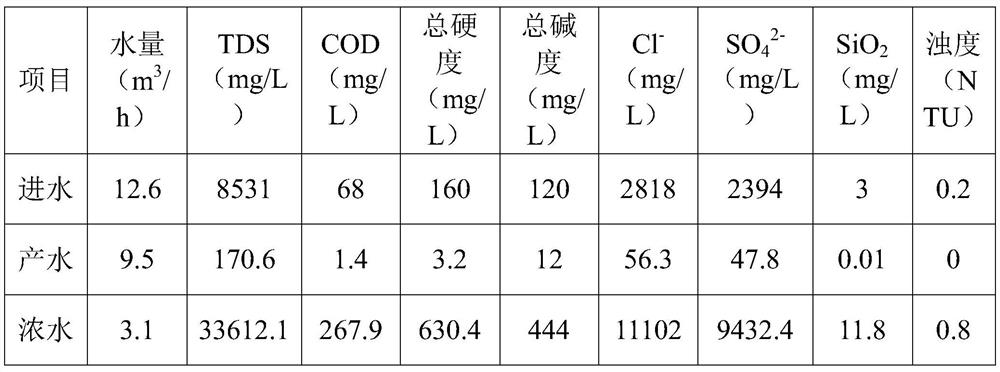

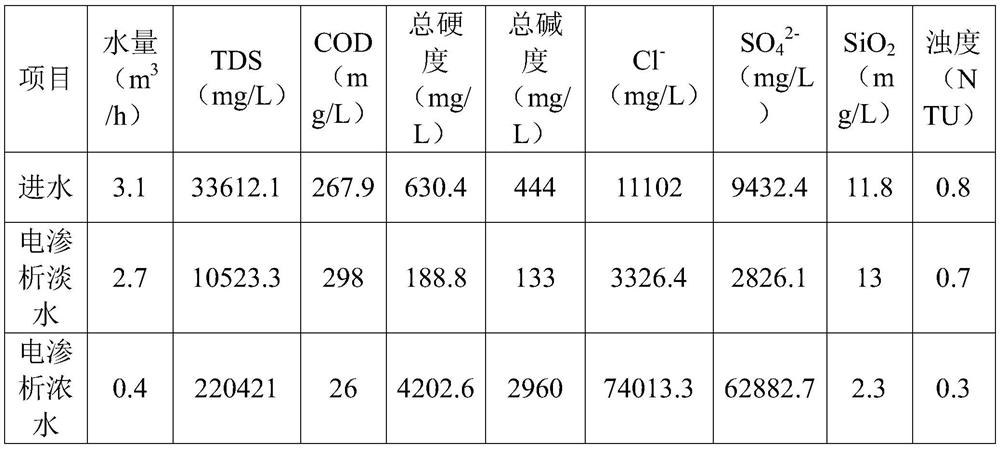

[0065] Taking a high-salt wastewater as an example, the flow Q=12m 3 / h, COD=68mg / L, TDS=7397mg / L, HCO 3- =110mg / L, Cl - =1837mg / L, SO 4 2- = 2394mg / L, total hardness = 2008mg / L, silicon dioxide 38mg / L, suspended solids = 5mg / L, pH = 8-9.

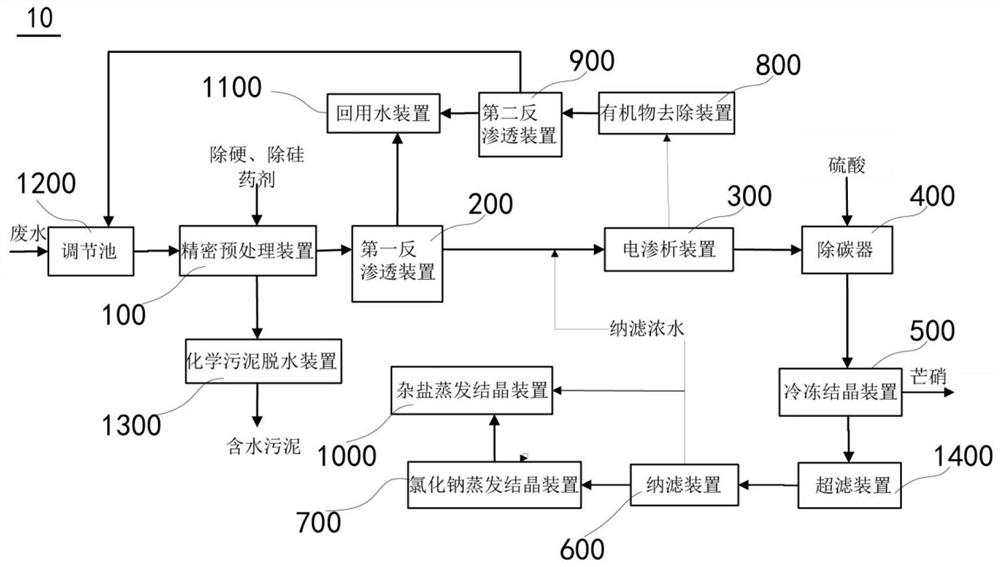

[0066] (1) Wastewater first enters the regulating tank 1200 for homogeneous adjustment of water quality and water volume, and then enters the precision pretreatment device 100 after stabilization. The precision pretreatment device 100 includes a high-density sedimentation tank, a V-shaped filter tank, and an ultrafiltration system. In the precision pretreatment device 100, adjust the pH value to 11.5 with sodium hydroxide, then add sodium carbonate, silicon remover, polyferric chloride, and PAM respectively, and remove calcium ions in the wastewater by means of coagulation, precipitation, and filtration , magnesium ions, suspended solids, colloids, silicon dio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| turbidity | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com