Preparation method for nanoscale composite structure molecular sieve

A composite structure and molecular sieve technology, applied in molecular sieves and base exchange compounds, nanotechnology, nanotechnology, etc., can solve the problems of molecular sieve catalytic performance degradation, achieve high activity and anti-carbon deposition ability, simplify synthesis process, and widely distribute acidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

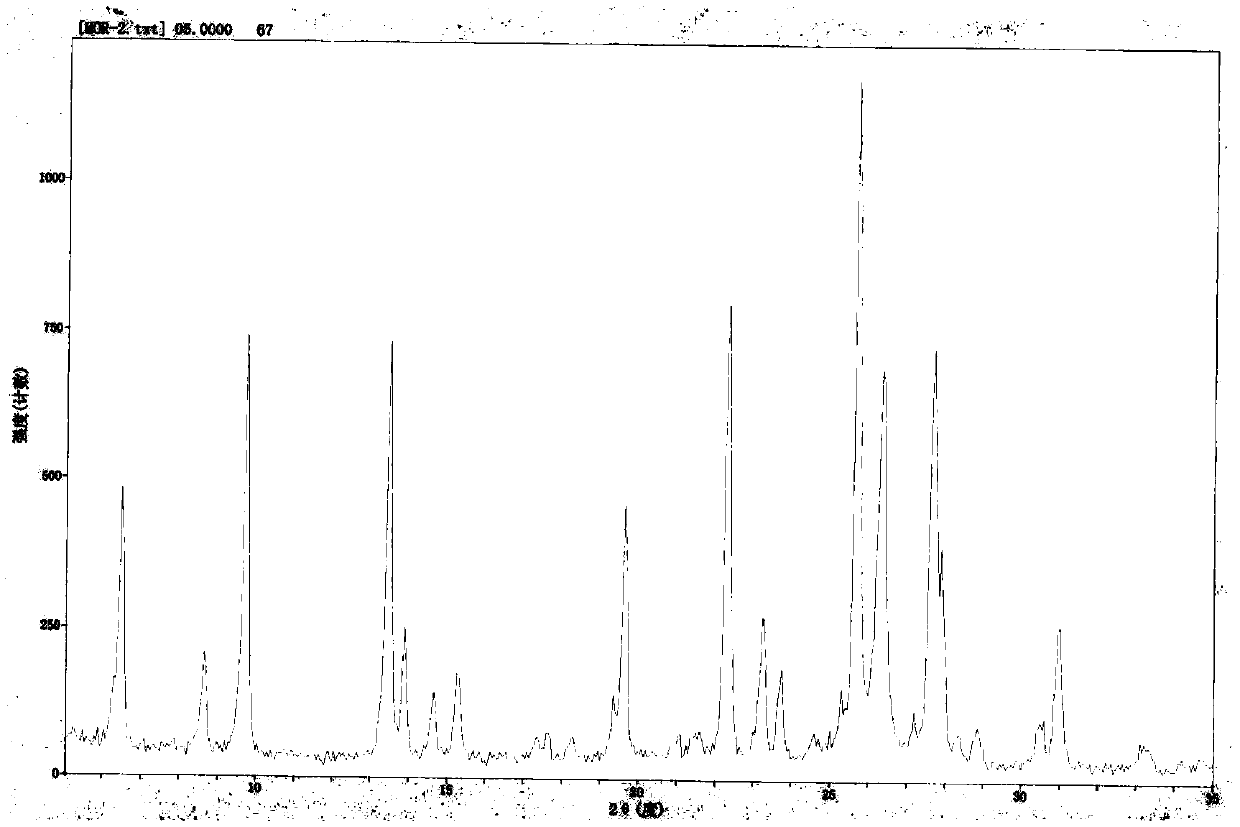

Image

Examples

Embodiment 1

[0027] A preparation method of molecular sieve with nanoscale composite structure, comprising the following steps:

[0028] (1) Add 1391g deionized water into the beaker, start stirring, add 60.9g sodium hydroxide, stir to dissolve, add 65.28g aluminum sol (AL2O3 content 25%), after stirring for 25min, slowly add 600g silica sol (SiO2 content 40%) %), the mixture sol was obtained after stirring for 2h;

[0029] (2) Transfer the mixture sol obtained in step (1) into a high-pressure crystallization kettle. The crystallization adopts a temperature program, and the temperature is raised to 168°C in 8 hours. After 24 hours at a constant temperature, the temperature is lowered and cooled. The value is 9;

[0030] (3) Mix the pre-configured 1800ml, 0.5mol / L sulfuric acid aqueous solution with the washed solid product, heat to 80°C, keep the temperature for 2h, filter and wash until the pH value is 4, stop at 120°C The molecular sieve with nanoscale composite structure is obtained b...

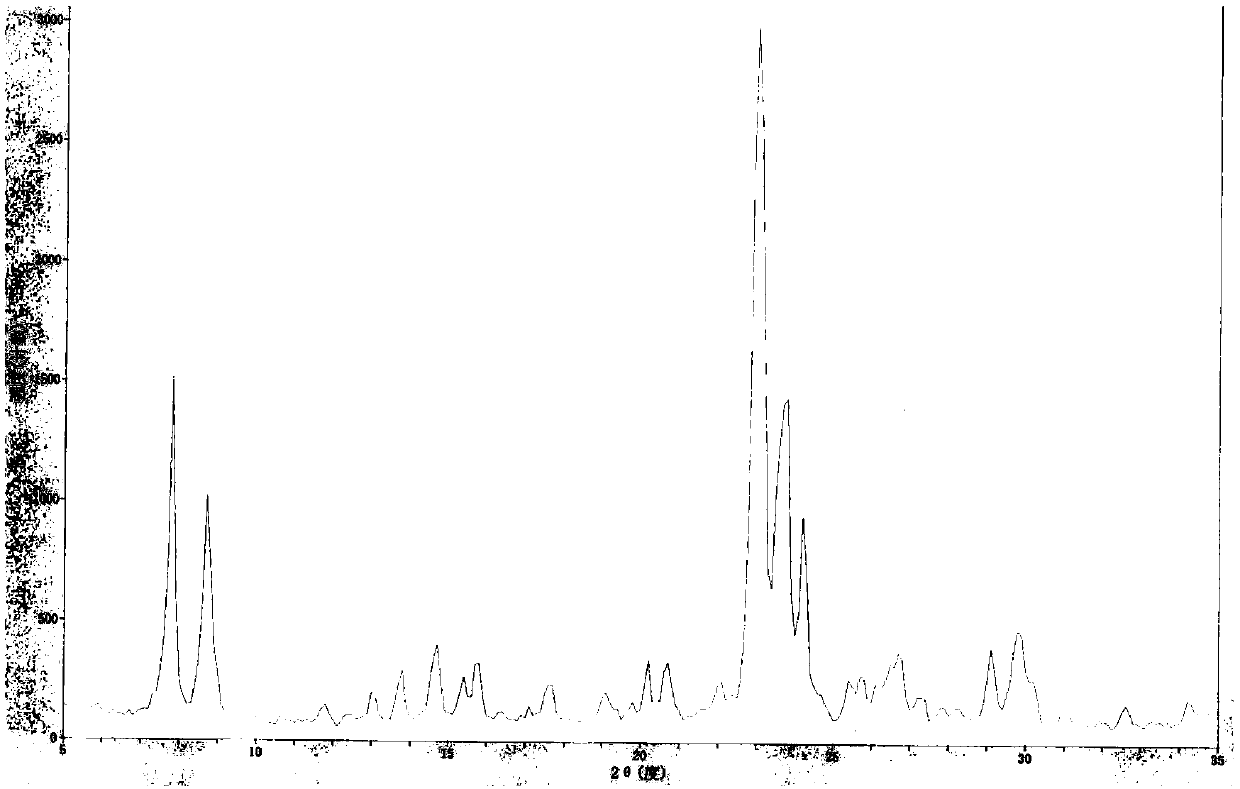

Embodiment 2

[0032] A preparation method of molecular sieve with nanoscale composite structure, comprising the following steps:

[0033] (1) Add 1756.3g deionized water into the beaker, start stirring, add 51.7g potassium hydroxide, stir to dissolve, add 58.29g aluminum sol (AL2O3 content 25%), stir for 30min, slowly add 600g silica sol (SiO2 content 40%), the mixture sol was obtained after stirring for 2 hours;

[0034] (2) Transfer the mixture sol obtained in step (1) into a high-pressure crystallization kettle. The crystallization adopts a temperature program, and the temperature is raised to 172°C in 8 hours. After 24 hours at a constant temperature, the temperature is lowered and cooled. value is 8;

[0035] (3) Mix the pre-configured 1800ml, 0.5mol / L sulfuric acid aqueous solution with the washed solid product, heat to 80°C, keep the temperature for 2h, filter and wash until the pH value is 5, stop it at 125°C The molecular sieve with nanoscale composite structure is obtained by dr...

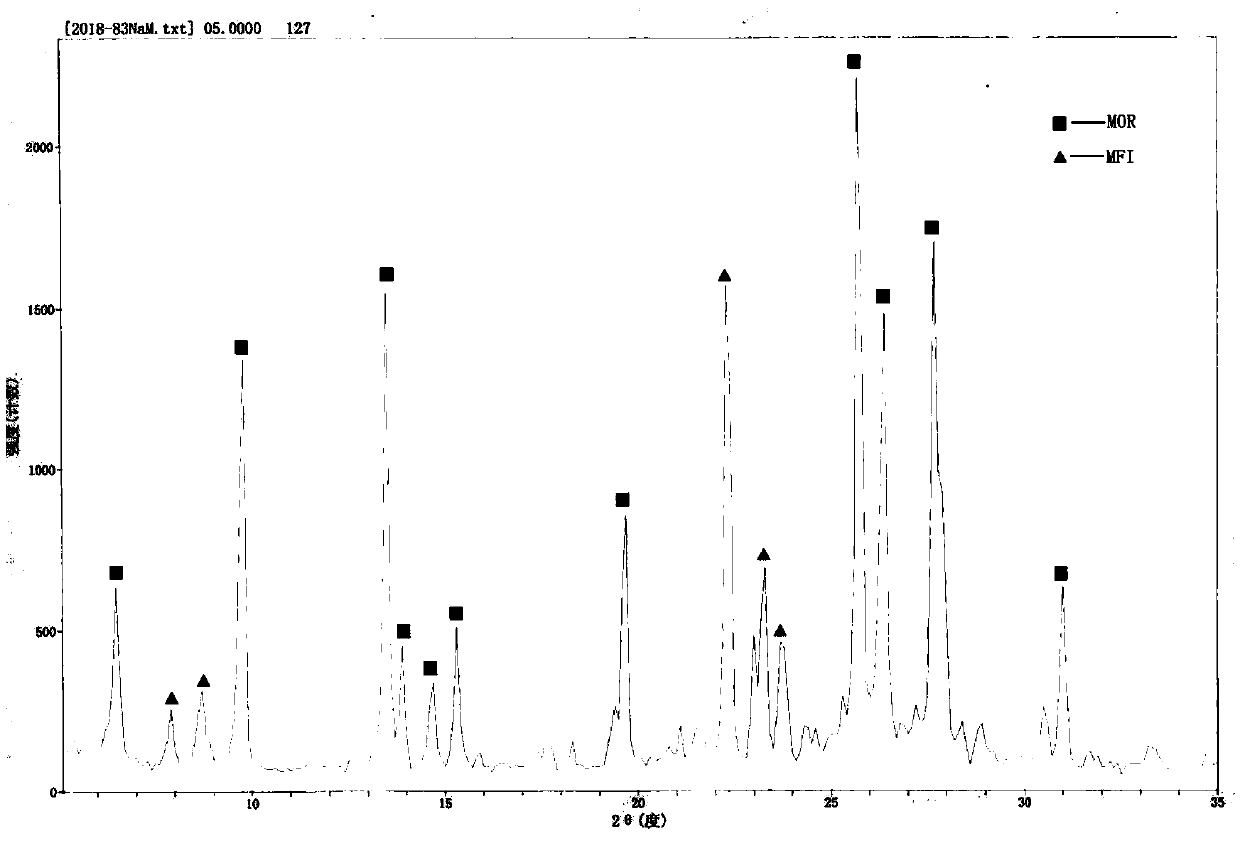

Embodiment 3

[0037] A preparation method of molecular sieve with nanoscale composite structure, comprising the following steps:

[0038] (1) Add 1610.67g deionized water into the beaker, start stirring, add 57.35g sodium hydroxide, stir to dissolve, add 60.44g aluminum sol (AL2O3 content 25%), stir for 35min, slowly add 600g silica sol (SiO2 content 40%), the mixture sol was obtained after stirring for 2 hours;

[0039] (2) Transfer the mixture sol obtained in step (1) into a high-pressure crystallization kettle. The crystallization adopts a temperature program, and the temperature is raised to 166°C in 8 hours. After 24 hours at a constant temperature, the temperature is lowered and cooled. The value is 9;

[0040] (3) Mix the pre-configured 1800ml, 0.5mol / L sulfuric acid aqueous solution with the washed solid product, heat to 80°C, keep the temperature for 2h, filter and wash until the pH value is 4, stop it at 130°C The molecular sieve with nanoscale composite structure is obtained by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com