Method for preparing polylactic acid porous support material

A technology of porous scaffold and polylactic acid, which is applied in medical science, prosthesis, etc., can solve the problem of small pore size of porous scaffold, and achieve the effect of no residue of impurities, simple process and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Preparation of Polylactic Acid Porous Scaffold

[0018] Dissolve polylactic acid in a mixed solvent of dioxane and water at a temperature of 40°C to 80°C to obtain a polylactic acid solution. The weight volume concentration of the polylactic acid solution is 1% to 10%. The volume ratio of water is 100 / 1 to 80 / 20; inject the above polylactic acid solution into the mold, roughen for 1 to 12 hours, and the roughening temperature is 10°C to 50°C. Freeze for 0.5 to 3 hours at ℃, and then freeze in a freeze dryer to obtain the polylactic acid porous scaffold of the present invention.

Embodiment 2

[0020] Effect of polylactic acid concentration on the performance of porous scaffolds

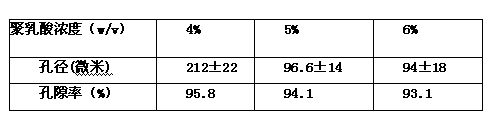

[0021] Dissolve poly-L-lactic acid in a mixed solvent of dioxane: water (volume ratio 85 / 15) at 80°C, and the weight-volume concentrations of poly-lactic acid are 4%, 5% and 6% (w / v), Pour into a glass mold with a diameter of 1.2cm and a thickness of 8cm, roughen at 25°C for 5 hours, freeze at -20°C for 1 hour, and then freeze-dry in a freeze dryer for 24 hours to obtain a three-dimensional poly-L-lactic acid porous scaffold . The effect of polylactic acid concentration on the pore size and porosity of porous scaffolds is shown in Table 1.

[0022] Table 1 Effect of polylactic acid concentration on the pore size and porosity of porous scaffolds

[0023]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com