Process of increasing energy conversion and electrochemical efficiency of a scaffold material using a deposition material

a technology of deposition material and scaffold material, which is applied in the direction of electrolysis inorganic material coating, regenerative fuel cell, electrical apparatus, etc., can solve the problems of poor mechanical properties, poor electrical conductivity of amorphous natural carbon with a low degree of graphitization, and interference with the mass transport of reactants, so as to increase the surface area of the scaffold material and increase the energy conversion and electrochemical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

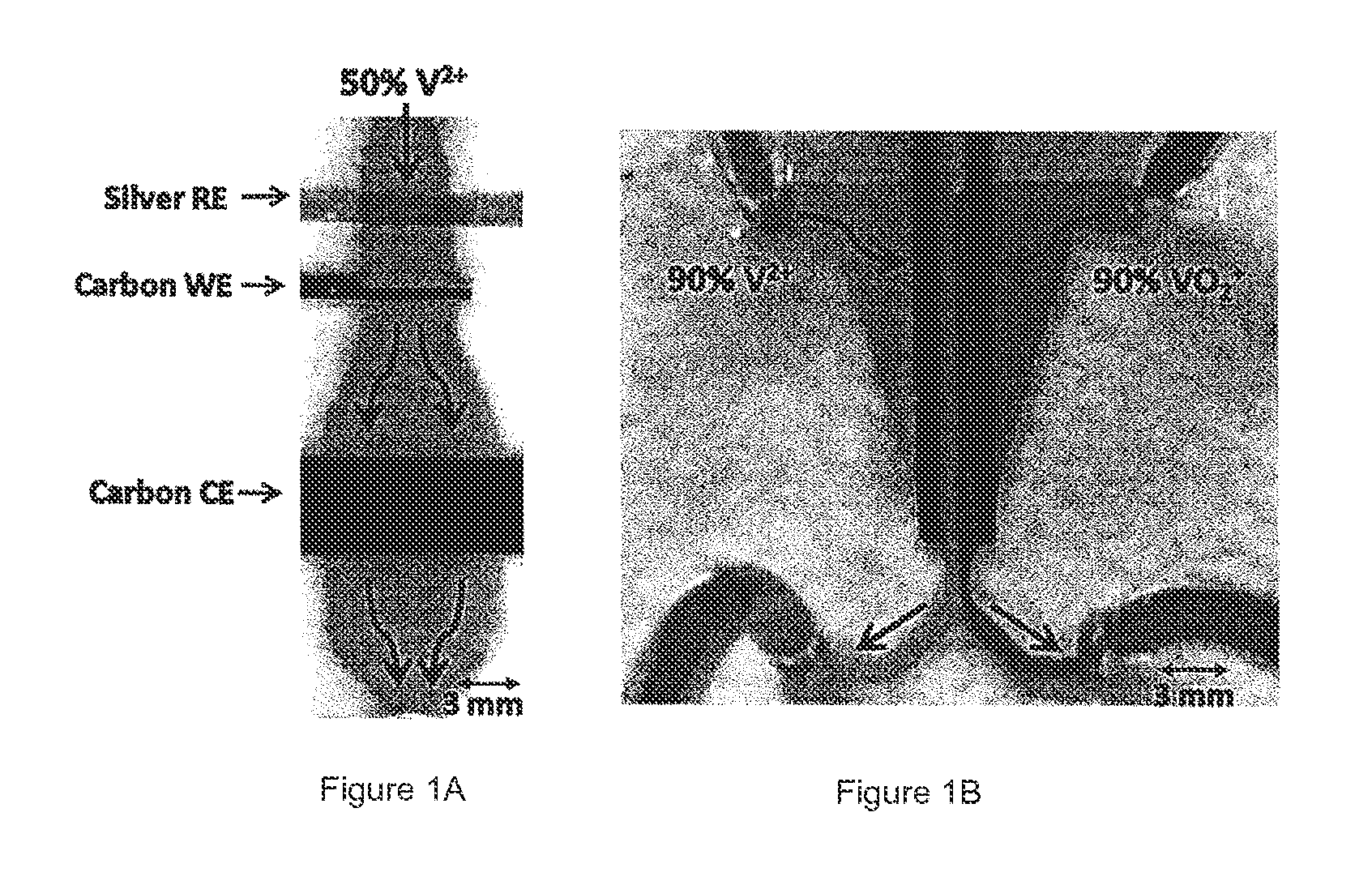

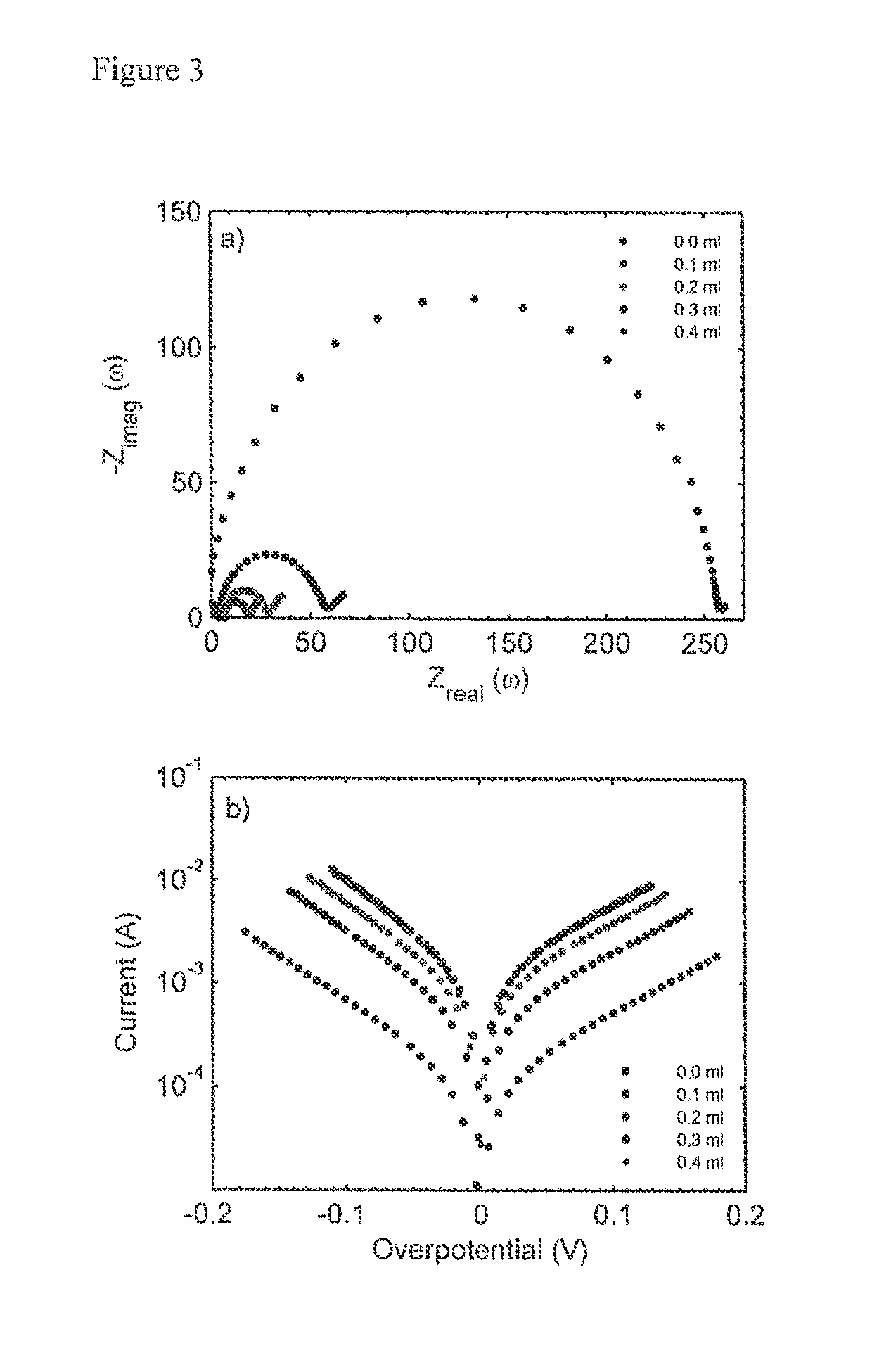

[0080]In both examples seen in FIG. 1, a customized microfluidic channel is used to force vanadium electrolyte through the electrodes. In the first case depicted in FIG. 1-a), the electrochemical cell in question is an analytical device used for characterization of materials. As such, it can be used to characterize, as it has in the present example, to characterize the deposition process. This method is used in addition to electrochemical impedance spectroscopy (EIS) to quantify the performance improvement of a novel CNT deposition process of the invention within flow-through porous electrodes. This deposition process is shown to increase the ESA of the carbon paper and the exchange current density of the V2+ / V3+ reaction by an order of magnitude. It is also shown that this process of the invention can be used in situ to enhance the reaction rates of the previously published / made microfluidic co-laminar flow cell (CLFC) based on vanadium redox reactants and carbon paper flow-through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore size | aaaaa | aaaaa |

| Electrical conductivity | aaaaa | aaaaa |

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com