Welding method of dissimilar metals and its products and applications

A technology of dissimilar metals and welding methods, applied in welding/welding/cutting items, applications, welding equipment, etc., can solve the problems of high welding process requirements, over-burning and other problems, achieve low welding process requirements, reduced weld bead brittleness, The effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

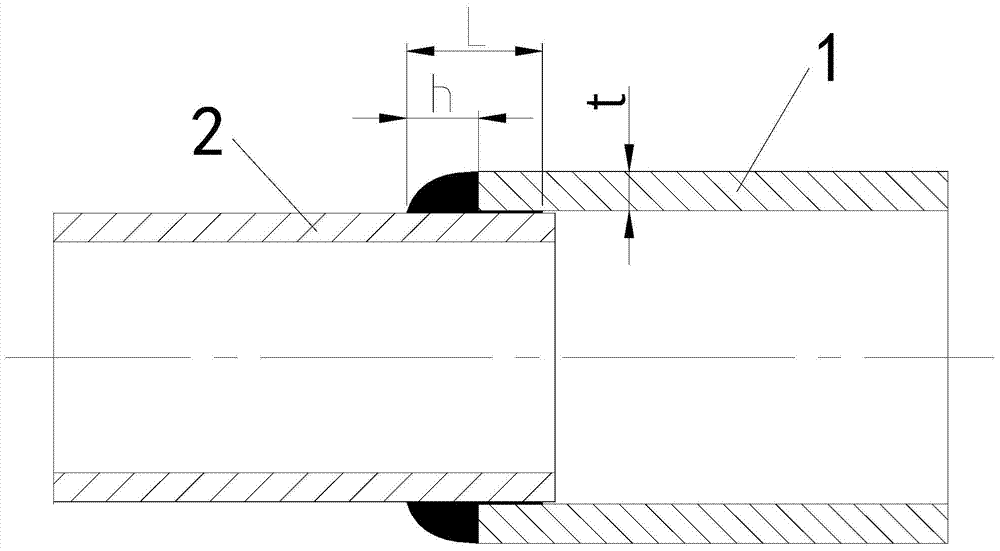

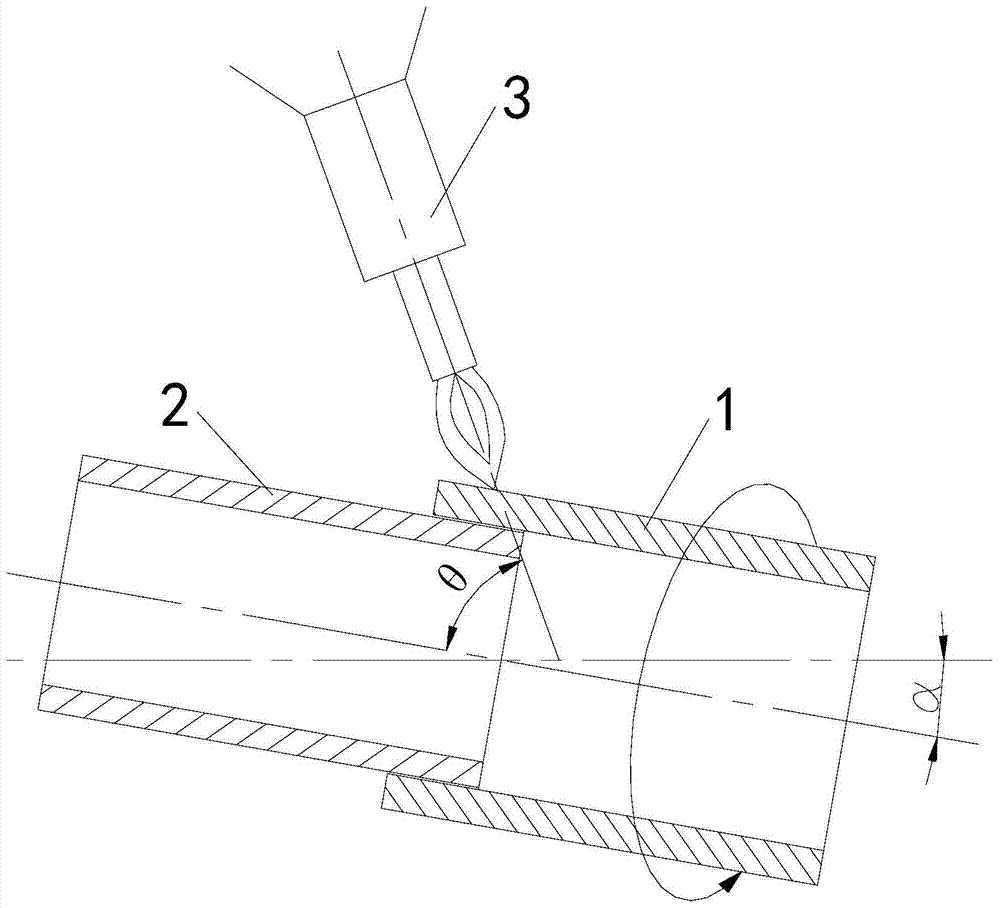

[0031] Such as figure 1 , figure 2 As shown, in this embodiment, a copper pipe 1 and an iron pipe 2 are adopted, and the copper pipe 1 is sleeved on the outside of the iron pipe 2 to form a weld. The wall thickness t of the copper pipe 1 is 1mm, and the wall thickness of the iron pipe is 0.8mm. The socket depth of the two is ≥1.5mm. After the copper tube 1 is socketed on the iron tube 2, the unilateral gap is 0-0.4mm. Since the expansion coefficient of copper is larger than that of iron, even if the unilateral gap is 0, once the copper tube 1 is heated and expanded, it will still contact the outer wall of the iron tube 2. A gap greater than 0 is formed.

[0032]Argon arc welding is used for welding, and the welding temperature is lower than the melting temperature of iron and higher than the melting temperature of copper. In this embodiment, the welding temperature is about 1200°C. The edge of the copper pipe 2 to be welded is melted as solder to seal the weld seam, and a...

Embodiment 2

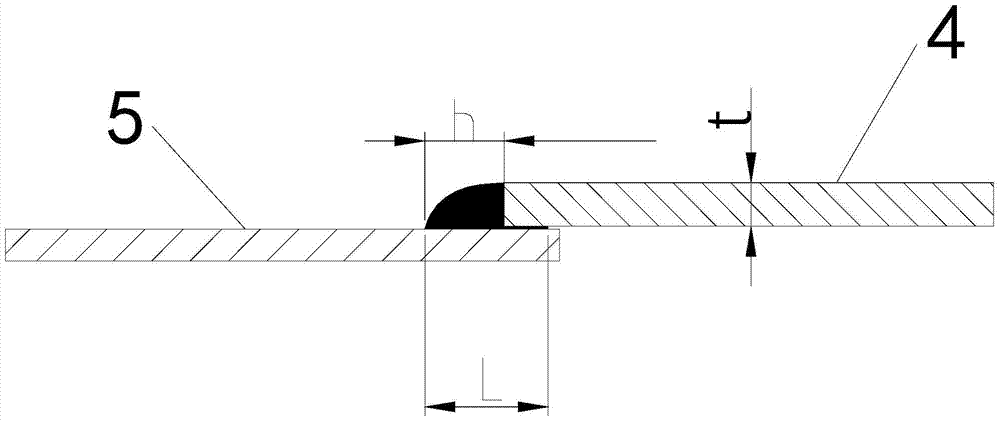

[0038] Such as image 3 , Figure 4 As shown, in this embodiment, a copper plate 4 and a stainless steel plate 5 are used, and the edge of the copper plate 4 is overlapped with the edge of the stainless steel plate 5 to be welded. The thickness t of the copper plate 4 is 3 mm, and the thickness t of the stainless steel plate 5 is 2 mm. The overlapping depth of the two is ≥1.5mm.

[0039] Argon arc welding is used for welding, and the welding temperature is lower than the melting temperature of iron and higher than the melting temperature of copper. In this embodiment, the welding temperature is about 1200°C. The edge of the copper plate 4 to be welded is melted as solder to seal the weld, and after cooling, a smooth slope with a certain radian is formed. The height of the slope is h=3mm, and the molten copper part is also filled into the weld. The width of the track is more than 3mm, so that the dissimilar metal plates including the copper plate 4 and the stainless steel pl...

Embodiment 3

[0042] When welding, nickel-based solder with a nickel content of more than 8% is used to melt the nickel solder and copper to form a mixture, which penetrates into the iron together to form a solid solution.

[0043] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com