Microcapsule fire-extinguishing agent

A technology of fire extinguishing agent and microcapsule, which is applied in the field of microcapsule fire extinguishing agent to achieve the effect of improving fire extinguishing efficiency, improving fire extinguishing effect and reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation process of microcapsule fire extinguishing agent is as follows:

[0033] (1) Weighing 82-95 g of potassium salt solution with a concentration of 0.5%-50%, 2-15 g of capsule shell material, and 0-5 g of additives;

[0034] (2) Heating the aqueous potassium salt solution to 60-95°C, adding 0-5g of the additive, and stirring until completely dissolved;

[0035] (3) Put the mixed liquid that has been stirred until completely dissolved in a high-speed stirring container, add the capsule shell material, set the rotation speed at 17000-28000r / min, and stir for 15-35s;

[0036] (4) Cool the stirred product at room temperature for 60-150 minutes to obtain the microcapsule fire extinguishing agent.

[0037] The microcapsule fire extinguishing agent of the present invention can also be prepared by a high-speed shearing method, other conventional soft capsule preparation methods, and hollow microsphere preparation methods.

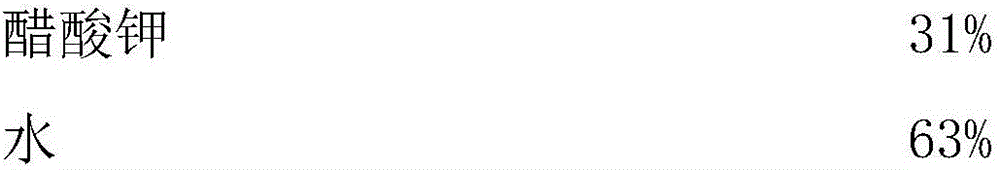

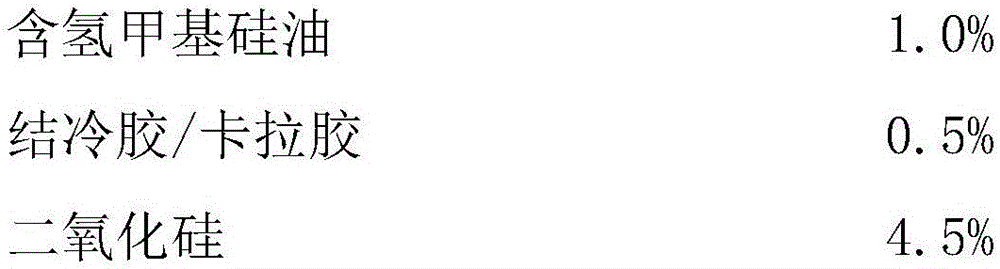

Embodiment 1

[0039] The microcapsule fire extinguishing agent of this embodiment is formed by mixing water, potassium acetate, hydrogen-containing methyl silicone oil, gellan gum / carrageenan, and granular silicon dioxide. Calculated by total weight, the weight percentage of each part is:

[0040]

[0041]

[0042] Preparation method: First, weigh 31g of potassium acetate and dissolve it in 63ml of hot water at 60°C. After the potassium acetate is completely dissolved, add 1g of hydrogen-containing methyl silicone oil and 0.5g of gellan gum / carrageenan, mix well, and place under high-speed stirring Add 4.5g of granular silicon dioxide to the container, stir at a high speed of 22000r / min for 25s, and cool the stirred product at room temperature for 60min to obtain a microcapsule fire extinguishing agent.

[0043] The fire extinguishing efficiency of the fire extinguishing agent of this embodiment is 10 times of the fire extinguishing efficiency of "GB4066.1--2004 dry powder fire extingu...

Embodiment 2

[0045] The microcapsule fire extinguishing agent of this embodiment is mixed by the mixture of water, potassium oxalate and potassium sorbate, additive phenolic resin, gelatin, granular silicon dioxide, calculated by total weight, the weight percentage of each part is:

[0046]

[0047] The preparation method is similar to that of Example 1, and the temperature of the hot water is raised to 80°C.

[0048] The fire extinguishing efficiency of the fire extinguishing agent of this embodiment is 10 times of the fire extinguishing efficiency of "GB4066.1--2004 dry powder fire extinguishing agent, the first part BC dry powder fire extinguishing agent".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com