Multi-wire bead welding system and process thereof

A welding process and process technology, which is applied in the multi-wire surfacing system and its process field, can solve the problems of expensive plasma arc surfacing equipment, dangerous process, narrow weld bead width, etc., and achieve wide weld seam and machining time Effect of reduction and high deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

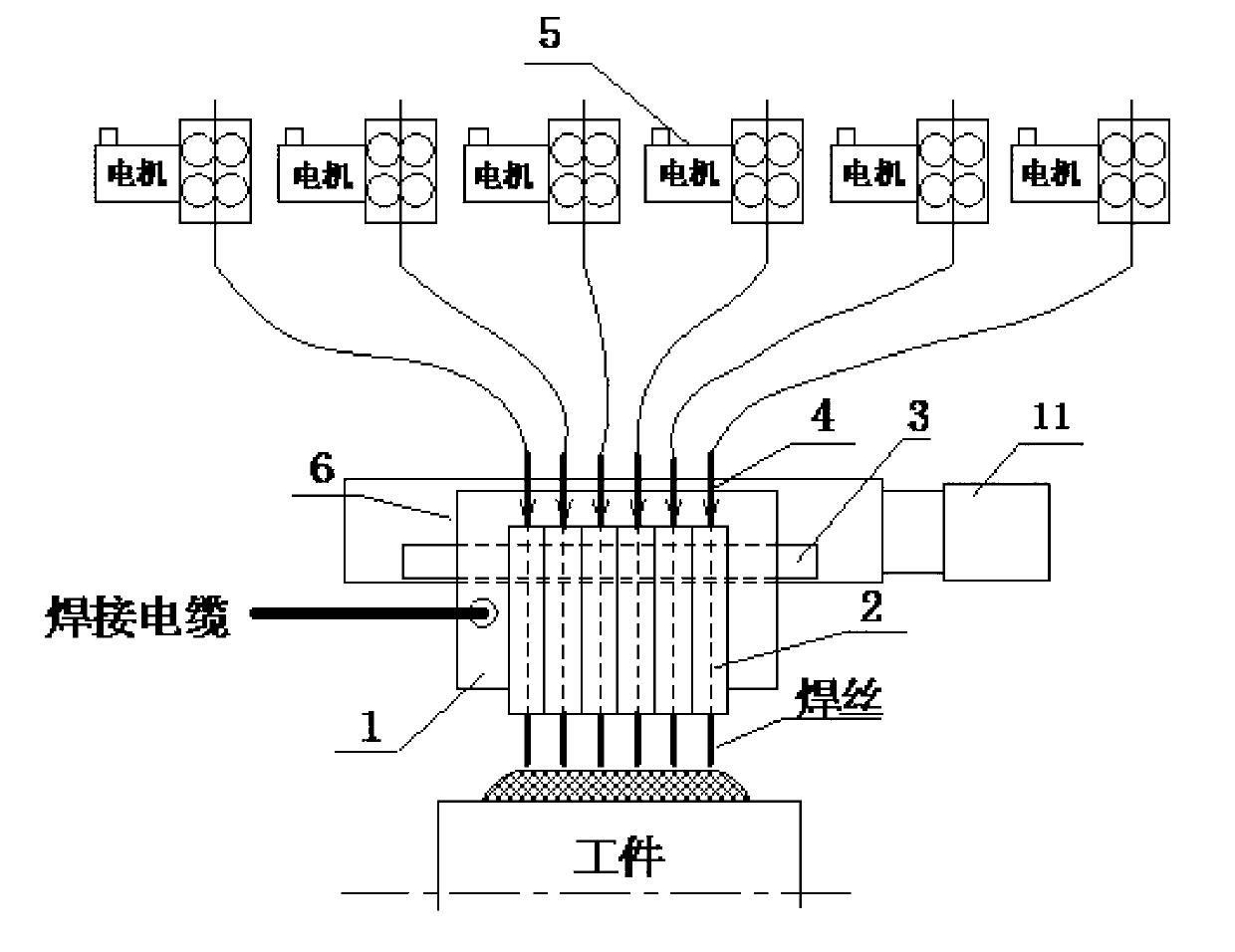

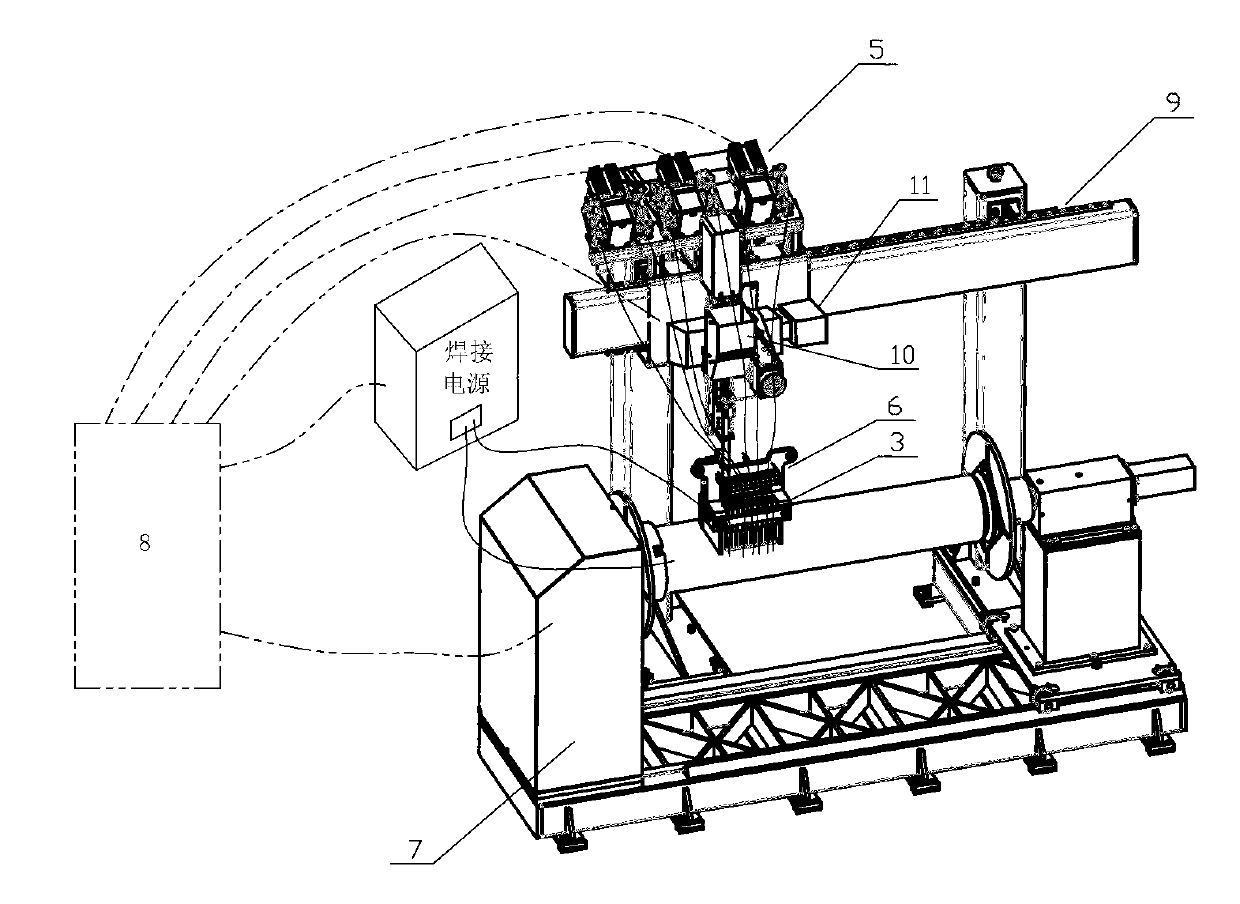

[0036] Taking 8-wire surfacing welding as an example, the multi-wire surfacing system includes a multi-wire welding torch, 8 wire feed tubes and two wire feeders. The multi-wire welding torch includes a welding torch body, 8 contact tips and cooling components. The cable is connected to the welding power source, the wire feed tube is fixed on the welding torch, and the positions of the wire feed tubes correspond to the contact tips. The wire feeder feeds the welding wires into the wire feed tubes of the multi-wire welding torch respectively, and the welding wires pass through the contact tips in parallel. The system It also includes a workpiece clamping rotary machine tool, a welding control system, and a welding torch traveling car. The multi-wire welding torch performs linear motion on the elongated rod of the welding torch traveling car. The welding control system communicates with the welding torch traveling car and the workpiece holder respectively It is connected with rot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com