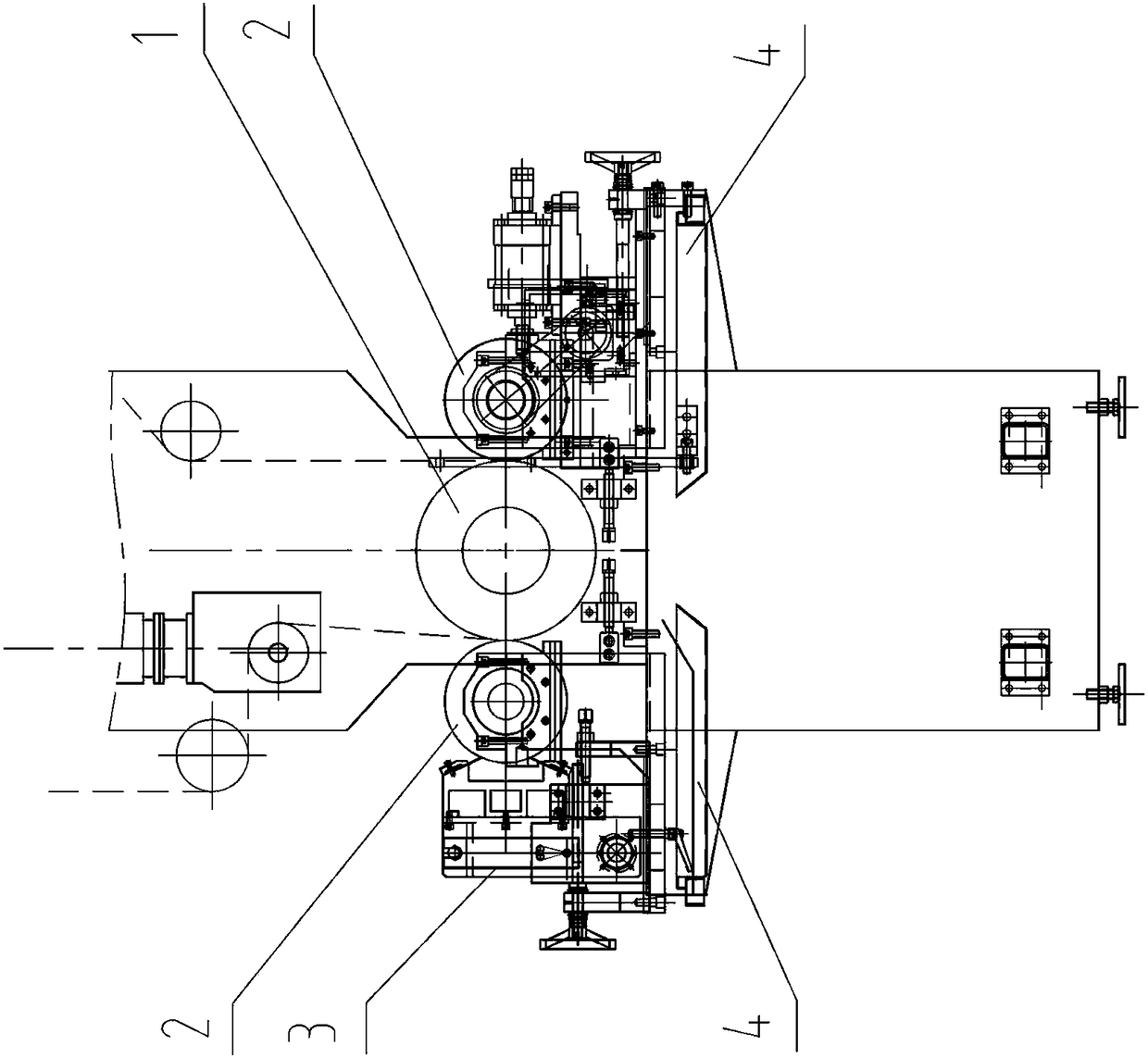

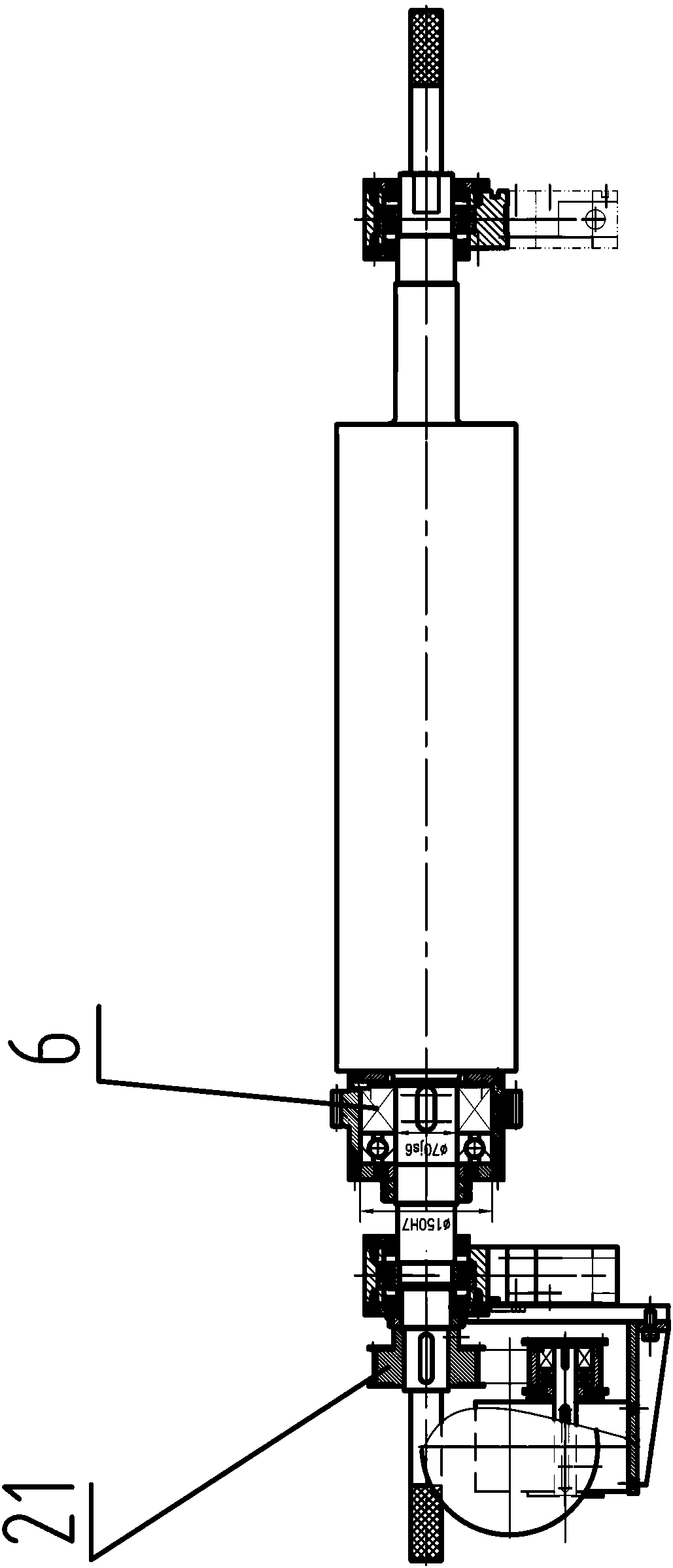

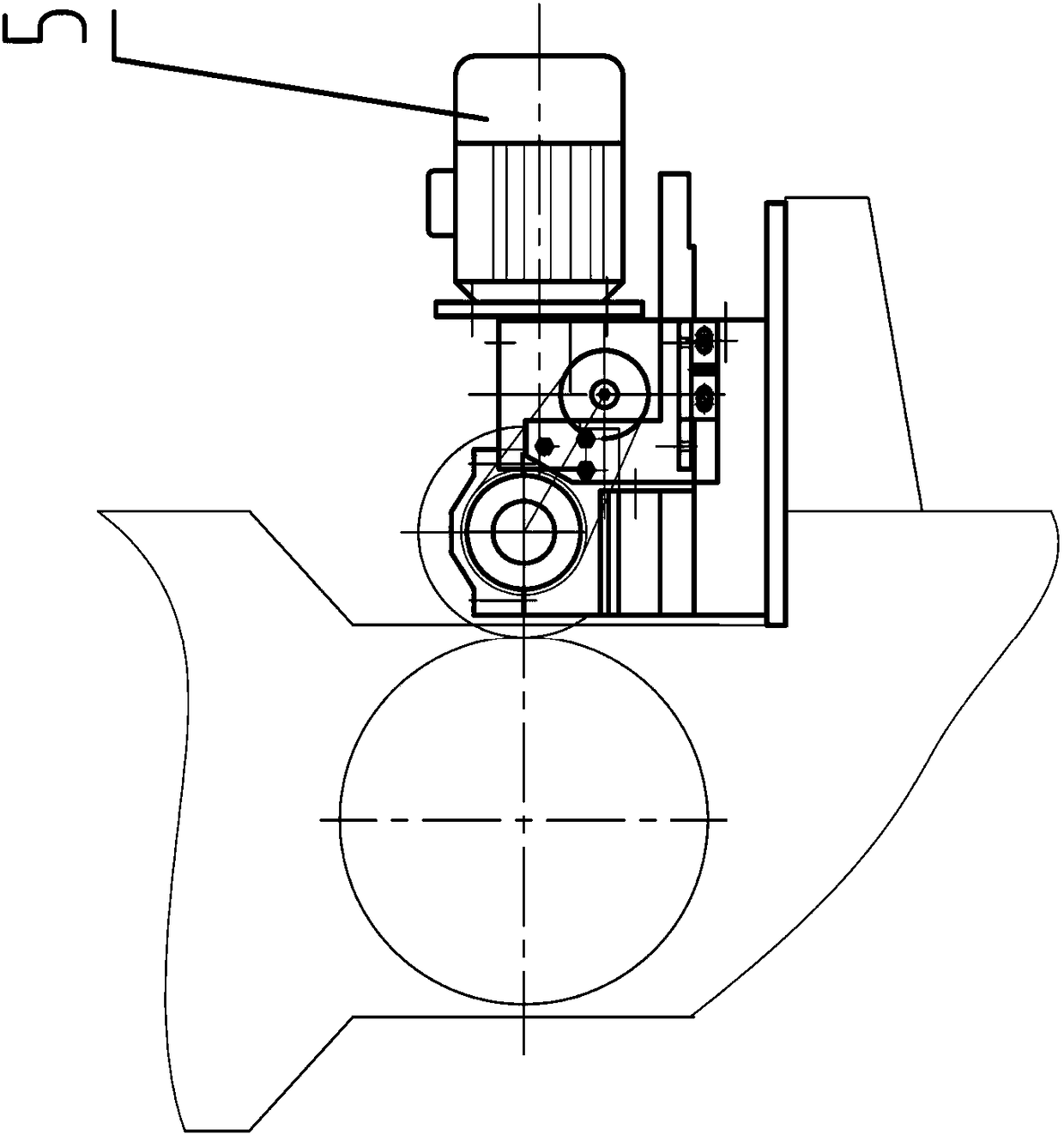

Anilox roller pretreatment device

A technology of anilox roller and main roller, which is applied in the processing of textile materials, processing of textile material drums, liquid/gas/steam textile material processing, etc., can solve the problems of high manufacturing cost and complicated mechanism, and achieve low sizing volume , uniform sizing, easy to control the effect of penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments for carrying out the present invention will be described below with reference to the drawings. It is to be noted that the embodiments described below are merely exemplary embodiments of the present invention, and those skilled in the art can appropriately modify detailed configurations within the scope not departing from the gist of the present invention. In addition, the numerical values used in the examples are reference numerical values and do not limit the present invention. It should also be understood that the dimensions, materials, forms, and relative arrangements of the components described below can also be appropriately modified according to the configuration and various conditions of the equipment to which the present invention is applied, and the scope of the present invention is not limited to those configurations unless explicitly stated .

[0023] The flow process of the transfer printing method is: first apply the pretreatment liquid to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com