Method for preparing polyurethane resin for high-wearing-resistance working gloves

A technology of polyurethane resin and labor protection gloves, applied in the field of synthetic leather, can solve problems such as limiting the application scope and application effect of polyurethane resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0011] The preparation method of the polyurethane resin for this high wear-resistant labor protection gloves comprises the following steps:

[0012] (1) polyglycol and isocyanate are carried out prepolymerization according to the ratio of the molar number of isocyanate and polyglycol in the ratio of (0.5~2.0): 1 in solvent dimethylformamide;

[0013] (II) Add auxiliary agent and glycol chain extender, continue heating to make prepolymer react with glycol chain extender;

[0014] (Ⅲ) adding isocyanate to continue the reaction, during the reaction, gradually add solvent and auxiliary agent in the system;

[0015] (Ⅳ) Detect the viscosity of the resin, when it reaches 2.2×10 5 ~2.6×10 5 At mPa·s / 25°C, add a small molecule monohydric alcohol to terminate the reaction, add additives and a small amount of solvent and stir well;

[0016] Wherein the sum of the moles of the polyglycol in the first step plus the moles of the diol chain extender in the second step is equal to the tot...

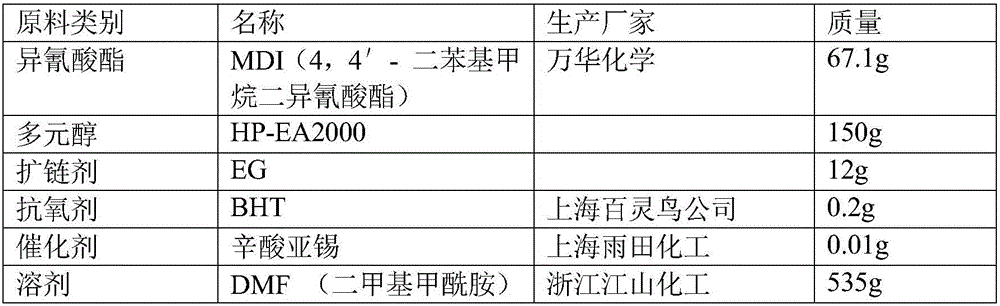

Embodiment 1

[0024] (a) Raw material ratio

[0025]

[0026] (b) Preparation process

[0027] (1) Add dihydric alcohol HP-EA2000, antioxidant, and DMF 100g into the reaction bottle, heat to 50°C and stir for 30 minutes; put in 37.5g of MDI, heat to 75°C for 2 hours to react.

[0028] (2) Add 200g of DMF and 12g of ethylene glycol, and react at a controlled temperature of 45°C for 30 minutes; add the remaining isocyanate in 2 times, and react at a controlled temperature of 75°C, each reaction time is 40 minutes, and 0.01g of catalyst is added in the middle to speed up the reaction. During the reaction process, add the remaining DMF as the viscosity increases, and then check the viscosity until the viscosity reaches 2.2×10 5 mPa·s / 25°C.

[0029] (3) 0.20 g of methanol was added to react for 150 min, and the material was unloaded to obtain 764 g of polyurethane resin with a solid content of 30%.

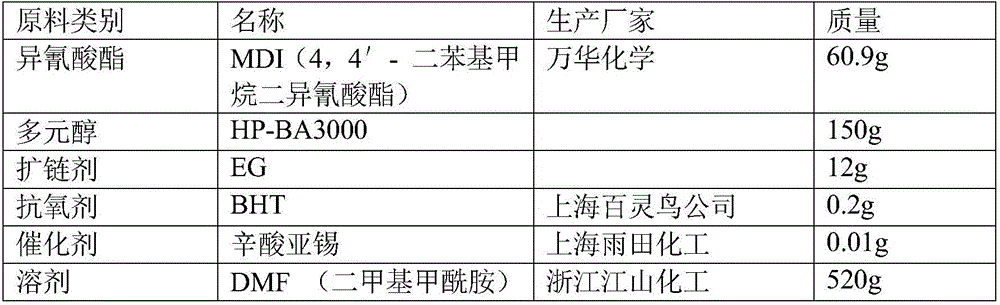

Embodiment 2

[0031] (a) Raw material ratio

[0032]

[0033] (b) Preparation process

[0034] (1) Add diol HP-BA3000, antioxidant, and DMF 90g into the reaction bottle, heat to 50°C and stir for 30 minutes; put in 22.5g of MDI, heat to 75°C for 2 hours to react.

[0035] (2) Add 250g of DMF, 12g of ethylene glycol, and react at a controlled temperature of 45°C for 30 minutes; add the remaining isocyanate in 2 times, and react at a controlled temperature of 75°C, each reaction time is 40 minutes, adding 0.01g of catalyst in the middle to speed up the reaction. During the reaction process, add the remaining DMF as the viscosity increases, and then check the viscosity until the viscosity reaches 2.2×10 5 mPa·s / 25°C.

[0036] (3) 0.20 g of methanol was added to react for 150 min, and the material was unloaded to obtain 743 g of polyurethane resin with a solid content of 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com