Unequal-thickness resistance spot welding method for GH4169 nickel-based high-temperature alloy clamp and strap

A nickel-based superalloy, GH4169 technology, applied in resistance welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of small heat input, reduced strength, large welding deformation of parts, etc., to improve the use function and reduce welding deformation And assembly error is small, the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

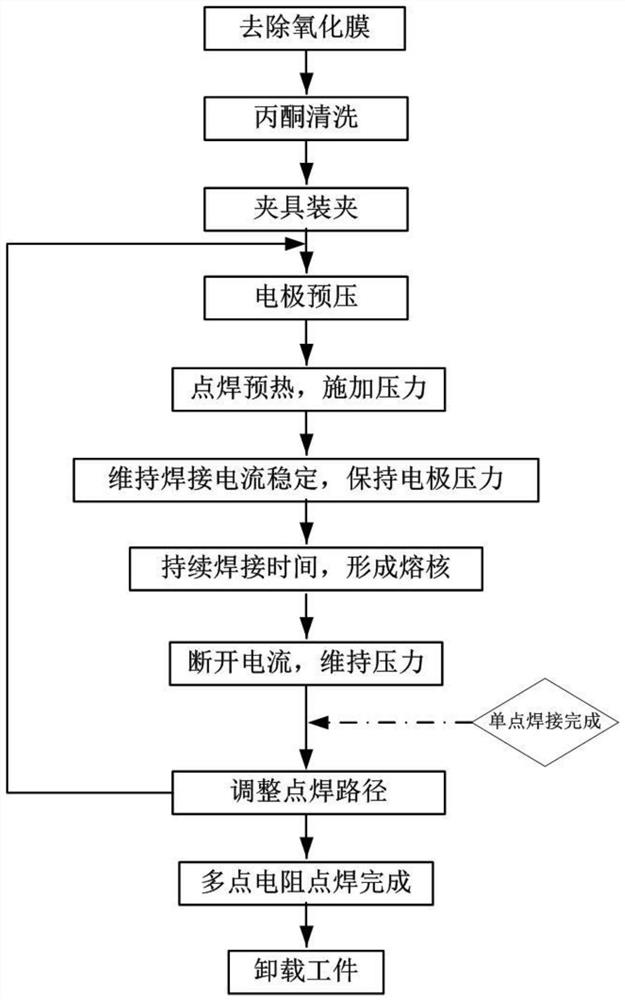

Method used

Image

Examples

Embodiment 1

[0039] (A) Pretreatment of GH4169 nickel-based superalloy clamps and GH4169 nickel-based superalloy bands: the thickness of the clamps used is 1.5mm, and the thickness of the bands is 0.8mm. Both materials are GH4169 nickel-based superalloys. The parts to be welded of the collar and the hoop are polished with SiC sandpaper to remove the oxide film existing on the surface, and then the surface of the hoop is cleaned with acetone and water to obtain a pre-treated workpiece. Finally, the pre-treated workpieces are placed on the welding table in the form of lap joints, and fixtures are used to ensure that there is no gap between the two unequal thickness workpieces.

[0040] (B) The electrode preload is applied by the spot welding robot, in which the upper and lower electrode heads are conical electrodes, the end diameter of the electrode is 3.5mm, the applied electrode preload is 9KN, and the preload time is 50ms. The pressure sensor and other feedback components are used to accu...

Embodiment 2

[0046](A) Pretreatment of GH4169 nickel-based superalloy clamps and GH4169 nickel-based superalloy bands: the thickness of the clamps used is 1.5mm, and the thickness of the bands is 0.8mm. Both materials are GH4169 nickel-based superalloys. The parts to be welded of the collar and the hoop are polished with SiC sandpaper to remove the oxide film existing on the surface, and then the surface of the hoop is cleaned with acetone and water to obtain a pre-treated workpiece. Finally, the pre-treated workpieces are placed on the welding table in the form of lap joints, and fixtures are used to ensure that there is no gap between the two unequal thickness workpieces.

[0047] (B) The electrode preload is applied by the spot welding robot, where the upper and lower electrode heads are cylindrical planar electrodes, the end diameter of the electrode is 4mm, the applied electrode preload is 8.5KN, and the preload time is 50ms. The pressure sensor and other feedback components are used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com