An electro-oxidative ozone generator

An ozone generator and electro-oxidation technology, applied in the direction of electrodes, electrolytic processes, electrolytic components, etc., can solve the problems of increased contact resistance, high energy consumption and temperature rise, long start-up time, etc., to achieve reduced resistance and energy consumption, high Ozone generation efficiency and the effect of simple equipment manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

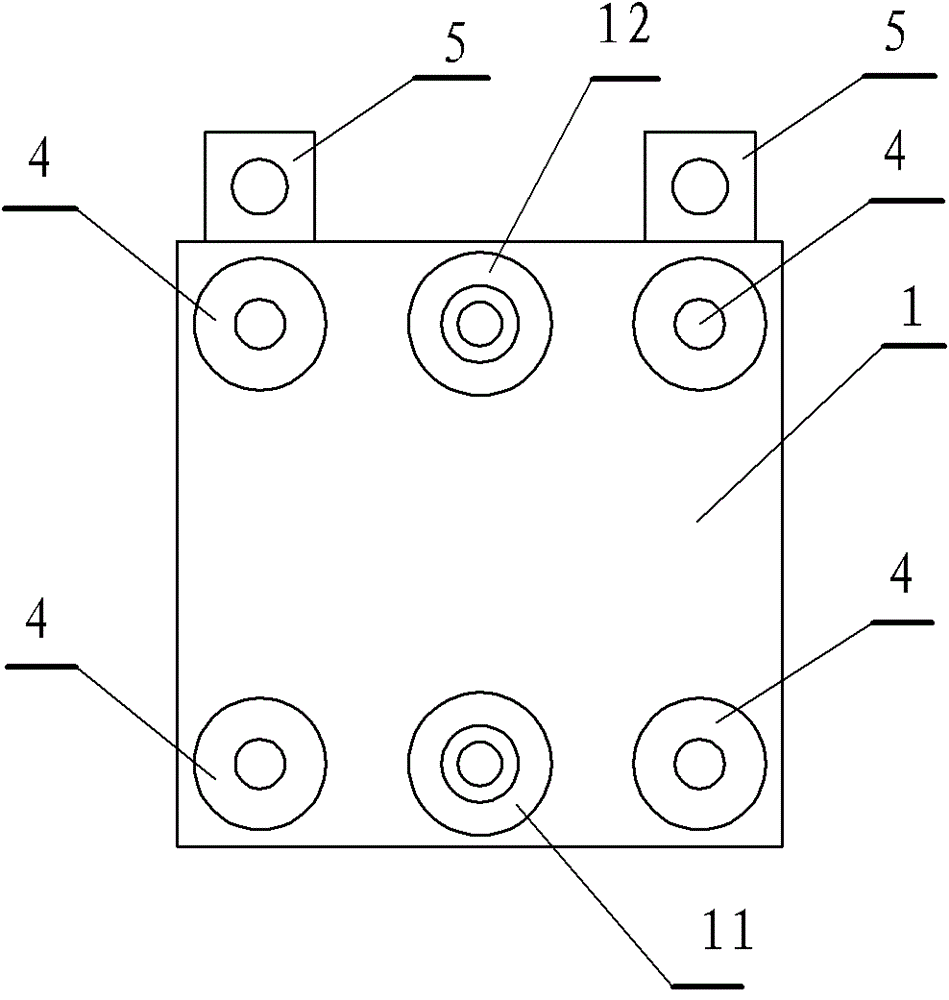

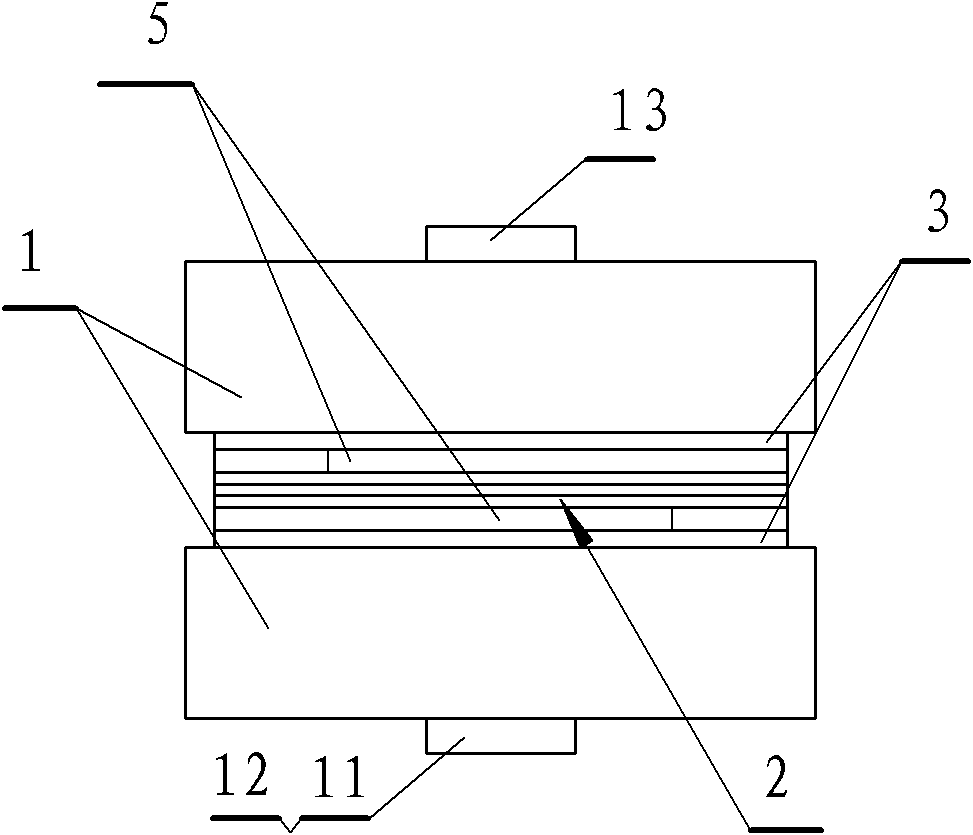

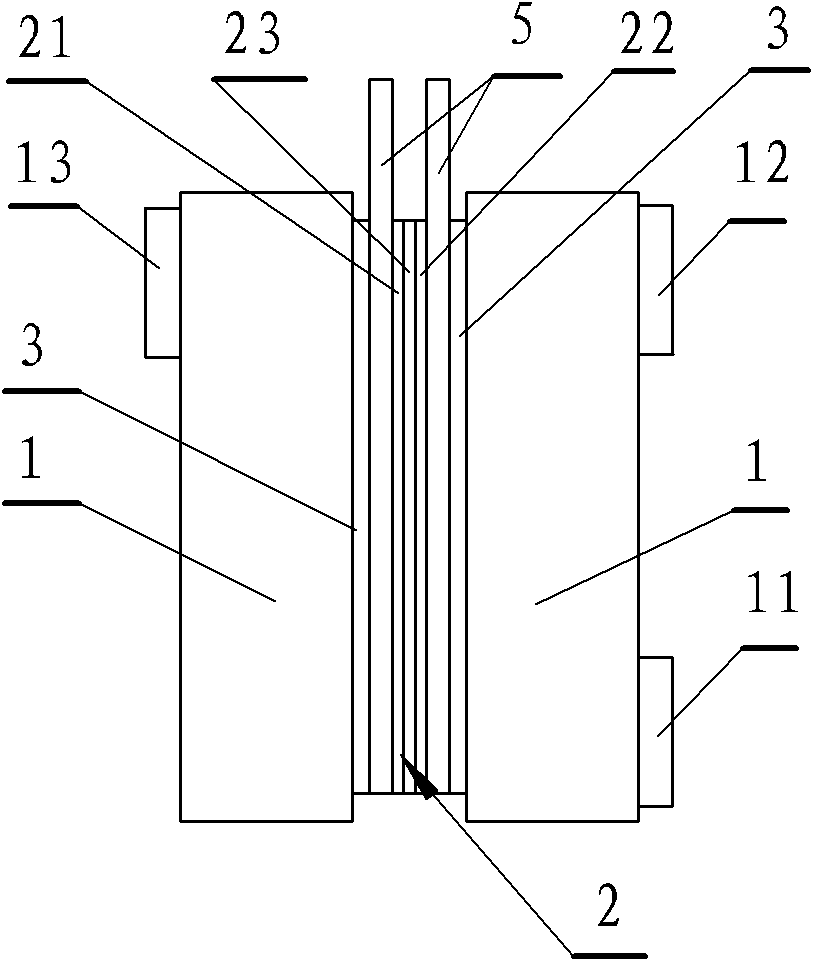

[0024] Such as Figures 1 to 3 and Figure 7 As shown, the electro-oxidation ozone generator of the present invention comprises the housing 1 of the electrolytic cell, the core component electrolytic electrode 2, and is formed by adding the gasket 3 and the fastener 4. The housing 1 is composed of two parts, and the middle clamp The inner cavity of the housing 1 is divided into an anode area and a cathode area by the electrolysis electrode 2. The upper part of the anode area is provided with an oxygen and ozone discharge port 12, and the lower part is provided with an electrolyte inlet 11. The upper part of the cathode area side is The hydrogen discharge port 13 provided, certainly the electrolytic solution import port 11 can be opened in the anode area and the cathode area and they are connected with a connecting pipe. The electrolysis electrode 2 then consists of an anodic membrane permeation electrode 21, a cathode membrane permeation electrode 22, an ion exchange membrane...

Embodiment 2

[0030] Such as Figures 4 to 7 As shown, the electro-oxidation ozone generator of the present invention comprises the housing 1 of the electrolytic cell, the core component electrolytic electrode 2, and is formed by adding the gasket 3 and the fastener 4. The housing 1 is composed of two parts, and the middle clamp The inner cavity of the housing 1 is divided into an anode area and a cathode area by the electrolysis electrode 2. The upper part of the anode area is provided with an oxygen and ozone discharge port 12, and the lower part is provided with an electrolyte inlet 11. The upper part of the cathode area side is The hydrogen discharge port 13 provided, certainly the electrolytic solution import port 11 can be opened in the anode area and the cathode area and they are connected with a connecting pipe.

[0031] The electrolysis electrode 2 is composed of an anodic membrane permeation electrode 21, a cathode membrane permeation electrode 22, an ion exchange membrane 23 sand...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com