Tee product preparation method

A tee and product technology, applied in the field of tee product preparation, can solve problems such as difficult production and manufacture, and the finished product cannot meet the needs of tee products, and achieves the effect of reducing the difficulty of research and development, avoiding repeated heating, and solving technical bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

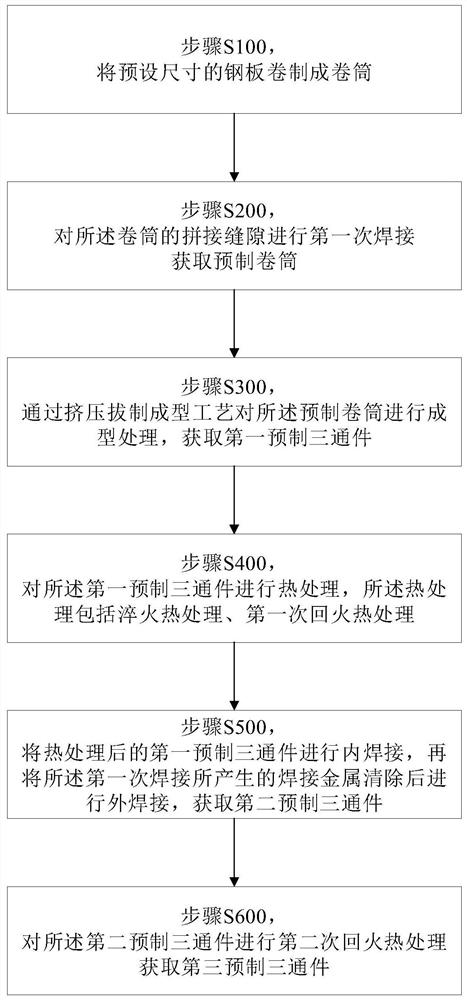

[0030] A kind of tee product preparation method of the present invention, this welding method comprises the following steps:

[0031] Step S100, rolling a steel plate with a preset size into a roll;

[0032] Step S200, performing the first welding on the splicing gap of the reel to obtain a prefabricated reel;

[0033] Step S300, forming the prefabricated roll through extrusion and drawing forming process to obtain the first prefabricated tee;

[0034] Step S400, performing heat treatment on the first prefabricated tee, and the heat treatment includes quenching heat treatment and first tempering heat treatment;

[0035] Step S500, performing internal welding on the heat-treated first prefabricated tee piece, and then removing the weld metal produced by the first welding and performing external welding to obtain a second prefabricated tee piece;

[0036] Step S600, performing a second tempering heat treatment on the second prefabricated three-way piece to obtain a third prefa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com